Metal-coated foamy copper-based self-supporting lithium cobalt oxide electrode material and manufacturing method thereof

A metal-coated, type-type lithium cobalt oxide technology, applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., can solve the problem of three-dimensional specific surface area shortening the lithium ion diffusion path, hindering the supply, rich active sites hindering practical applications, etc. problems, to achieve significant electrochemical performance, high porosity, and significant cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

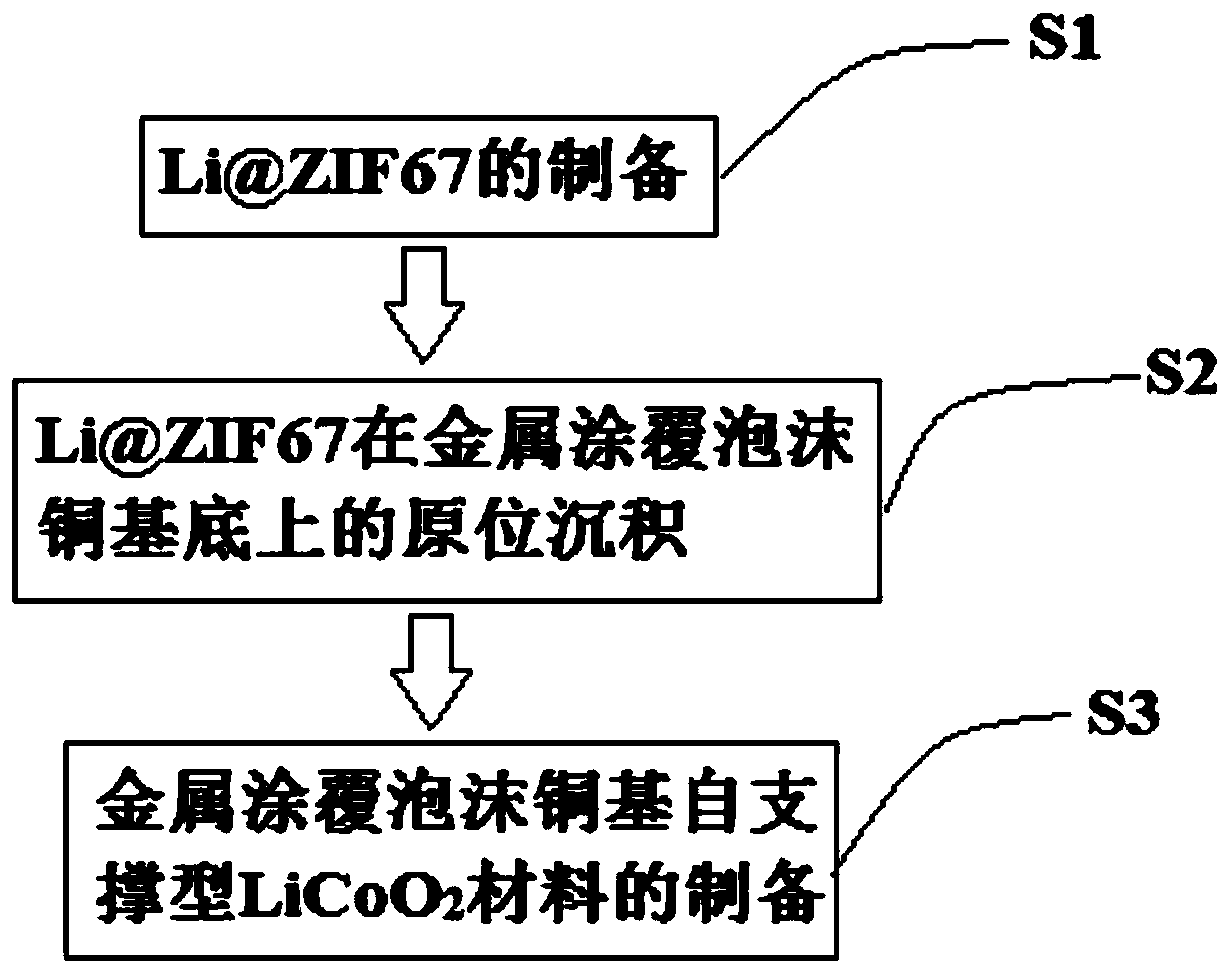

[0060] see figure 1 , in fact, the flow chart of the method for preparing metal-coated foamed copper-based self-supporting lithium cobaltate electrode material of the present invention, the method has the following steps:

[0061] Step S1: Preparation of Li@ZIF67;

[0062] Co(NO 3 ) 2 ·6H 2 O and cetyltrimethylammonium bromide (CTAB) were dissolved in methanol to prepare solution A, and then 2-methylimidazole and Li 2 CO 3 Dissolved in methanol to prepare solution B, then quickly pour solution B into solution A to form mixed solution C, centrifuge the mixed solution C after microwave reaction, wash, and dry to prepare lithium-ion-doped ZIF67 (Li@ ZIF67).

[0063] ZIF series materials are usually synthesized by one-step method, through the reaction of metal salts and organic ligands in a solvent. The commonly used preparation methods also include solvothermal method, liquid phase diffusion method, microwave-assisted method, electrochemical method and mechanochemical synt...

Embodiment 1

[0076] Step S1: Preparation of Li@ZIF67;

[0077] S101: Dissolved, 2.4g of 99% Co(NO 3 ) 2 ·6H 2 O, 0.2g purity is that the CTAB of 99% is dissolved in the 30mL methyl alcohol, stirs and makes it dissolve completely, makes solution A; With 3.3g purity is 99% 2-methylimidazole, 0.4gLi 2 CO 3 Dissolve in 60mL of methanol, stir to dissolve completely, and obtain solution B;

[0078] S102: Microwave reaction, quickly pour solution B into solution A to form a mixed solution, then place the mixed solution in a microwave reactor at a constant temperature of 50°C for 5 minutes, and cool it to room temperature after obtaining a purple solution;

[0079] S103: Centrifuge, centrifuge the purple solution at a speed of 7000r / min for 3 minutes, and collect the solid product;

[0080] S104: washing and drying, using methanol to ultrasonically clean the solid product three times, and vacuum-drying the washed solid product at 60° C. for 24 hours to prepare Li@ZIF67.

[0081] Step S2: in-...

Embodiment 2

[0090] Step S1: Preparation of Li@ZIF67;

[0091] S101: Dissolve, 2.0g of 99% Co(NO 3 ) 2 ·6H 2 O, the CTAB that 0.1g purity is 99% is dissolved in the 30mL methyl alcohol, stirs and makes it dissolve completely, makes solution A; 3.0g purity is 99% 2-methylimidazole, 0.35gLi 2 CO 3 Dissolve in 60mL of methanol, stir to dissolve completely, and obtain solution B;

[0092] S102: Microwave reaction, quickly pour solution B into solution A to form a mixed solution, then place the mixed solution in a microwave reactor at a constant temperature of 50°C for 5 minutes, and cool it to room temperature after obtaining a purple solution;

[0093] S103: Centrifuge, centrifuge the purple solution at a speed of 7000r / min for 3 minutes, and collect the solid product;

[0094] S104: washing and drying, using methanol to ultrasonically clean the solid product three times, and vacuum-drying the washed solid product at 60° C. for 24 hours to prepare Li@ZIF67.

[0095] Step S2: in-situ dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com