Preparation method of low-density refractory high-entropy alloy cladding layer for laser cladding

A high-entropy alloy and laser cladding technology, which is applied in the coating process and coating of metal materials, can solve the problems that titanium alloys cannot be endowed with long-term service conditions, cannot meet high-strength applications, and have poor microstructure compactness. Achieve excellent binding properties, good macroscopic morphology, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

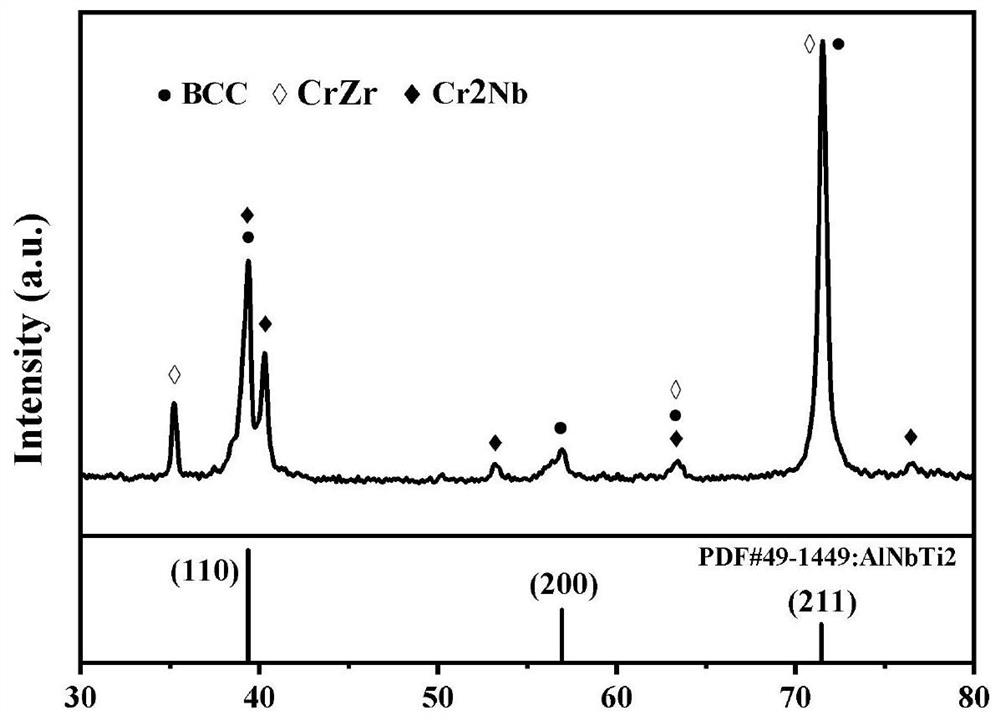

[0029] S1: The high-entropy alloy material described in this example is composed of six metal element powders of Ti, Al, Mo, Nb, Cr and Zr, and the molar ratio of each component is 1:1:1:1:1:1; After each powder is weighed and mixed in proportion, it is vacuum ball milled for 3 hours to obtain an alloy powder with a particle size of 200-325 mesh;

[0030] S2: TC4 (Ti6-Al4-V) is selected as the base material, polished with 200-400 mesh sandpaper to remove surface oxides, oil stains are removed with acetone, and cleaned with ultrasonic alcohol;

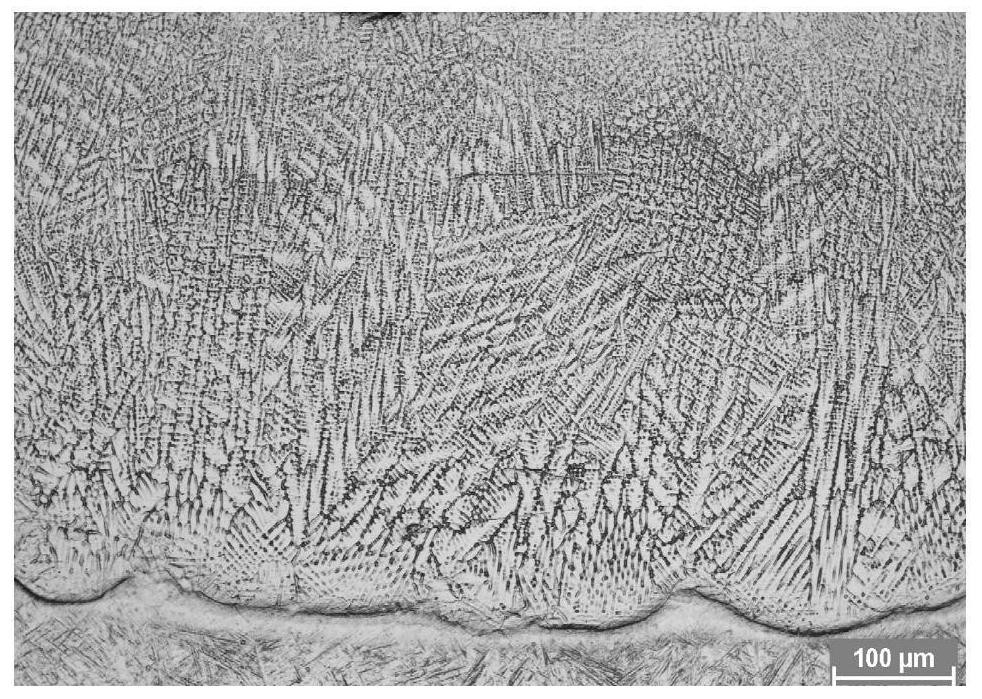

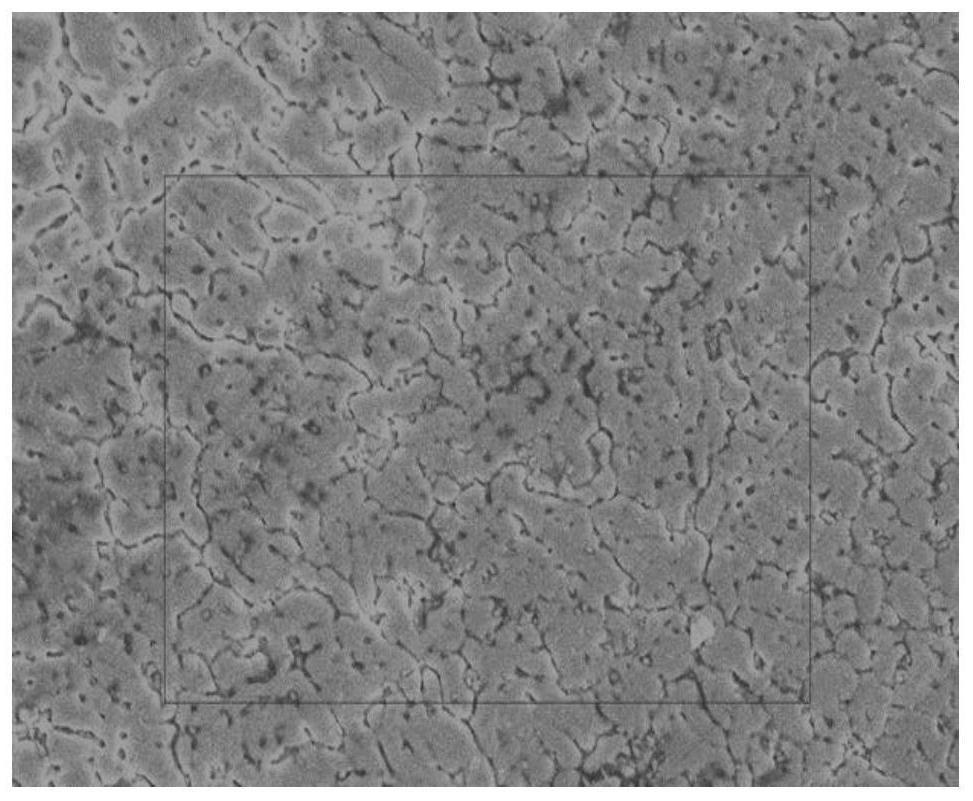

[0031] S3: Press the alloy powder obtained in S1 evenly on the surface of the substrate treated in S2 to form a prefabricated layer with a thickness of 1.2mm, put it in an 80°C drying oven, dry it for 10 hours, and then obtain it by laser cladding For the cladding layer, the process parameters during laser cladding are: laser power 3700W, scanning speed 300mm / min, spot diameter 3.5mm, defocusing distance 20mm, protective gas Ar, gas flo...

Embodiment 2

[0033] S1: The high-entropy alloy material described in this example is composed of six metal element powders of Ti, Al, Mo, Nb, Cr and Zr, and the molar ratio of each component is =1:1:1:1:1:1, After weighing and mixing each powder in proportion, vacuum ball milling was carried out for 3 hours to obtain alloy powder with a particle size of 200-325 mesh;

[0034] S2: TC4 (Ti6-Al4-V) is selected as the base material, polished with 200-400 mesh sandpaper to remove surface oxides, oil stains are removed with acetone, and cleaned with ultrasonic alcohol;

[0035] S3: Press the alloy powder obtained in S1 evenly on the surface of the substrate treated in S2 to form a prefabricated layer with a thickness of 1.2mm, put it in an 80°C drying oven, dry it for 10 hours, and then obtain it by laser cladding For the cladding layer, the process parameters during laser cladding are: laser power 4200W, scanning speed 350mm / min, spot diameter 3.5mm, defocusing distance 20mm, protective gas Ar,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com