Anti-high temperature oxidation coating material and hot dipping process for hot stamping steel

A hot stamping forming, high temperature oxidation resistance technology, applied in hot dip plating process, metal material coating process, coating and other directions, can solve the problem of uneven distribution of elements and organization, waste liquid easily polluting the environment, and high surface roughness problems, to achieve good high temperature oxidation resistance, reduce energy consumption, and achieve good coating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

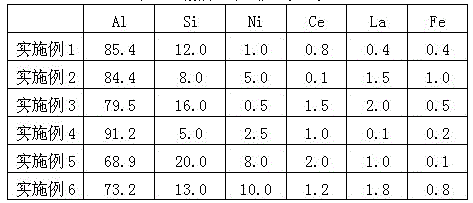

[0022] Examples 1-6: The chemical composition of the plating solution of the high-temperature oxidation-resistant coating for hot stamping steel is shown in Table 1, the main production process of the coating is shown in Table 2, and the main indicators of the obtained coating are shown in Table 3.

[0023] Table 1: Chemical composition of plating solution (wt%)

[0024]

[0025] Table 2: Main production process (parameters)

[0026]

[0027] In Table 2, the temperature of the steel plate refers to the temperature when the steel plate enters the plating solution, that is, the steel plate at this temperature enters the plating solution.

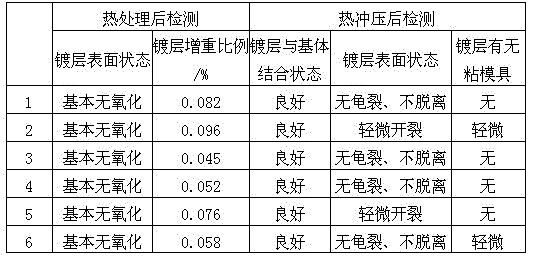

[0028] Table 3: Main anti-oxidation and hot stamping performance indicators of the coating

[0029]

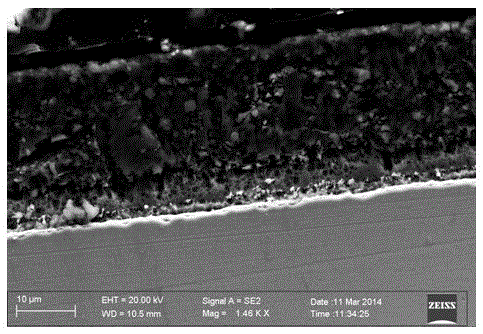

[0030] In Table 3, the weight gain ratio of the coating = (weight before plating - weight after plating) / weight after plating; the combined state of the coating and the substrate is observed by scanning.

[0031] Depend on figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com