Method for preparing cation ester-based type soap-free emulsion polymer

A soap-free emulsion and polymer technology, applied in the fields of emulsion polymerization and polymer synthesis, can solve problems such as latex particles that are not well solved, and achieve the effects of significant entanglement, high reaction efficiency and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

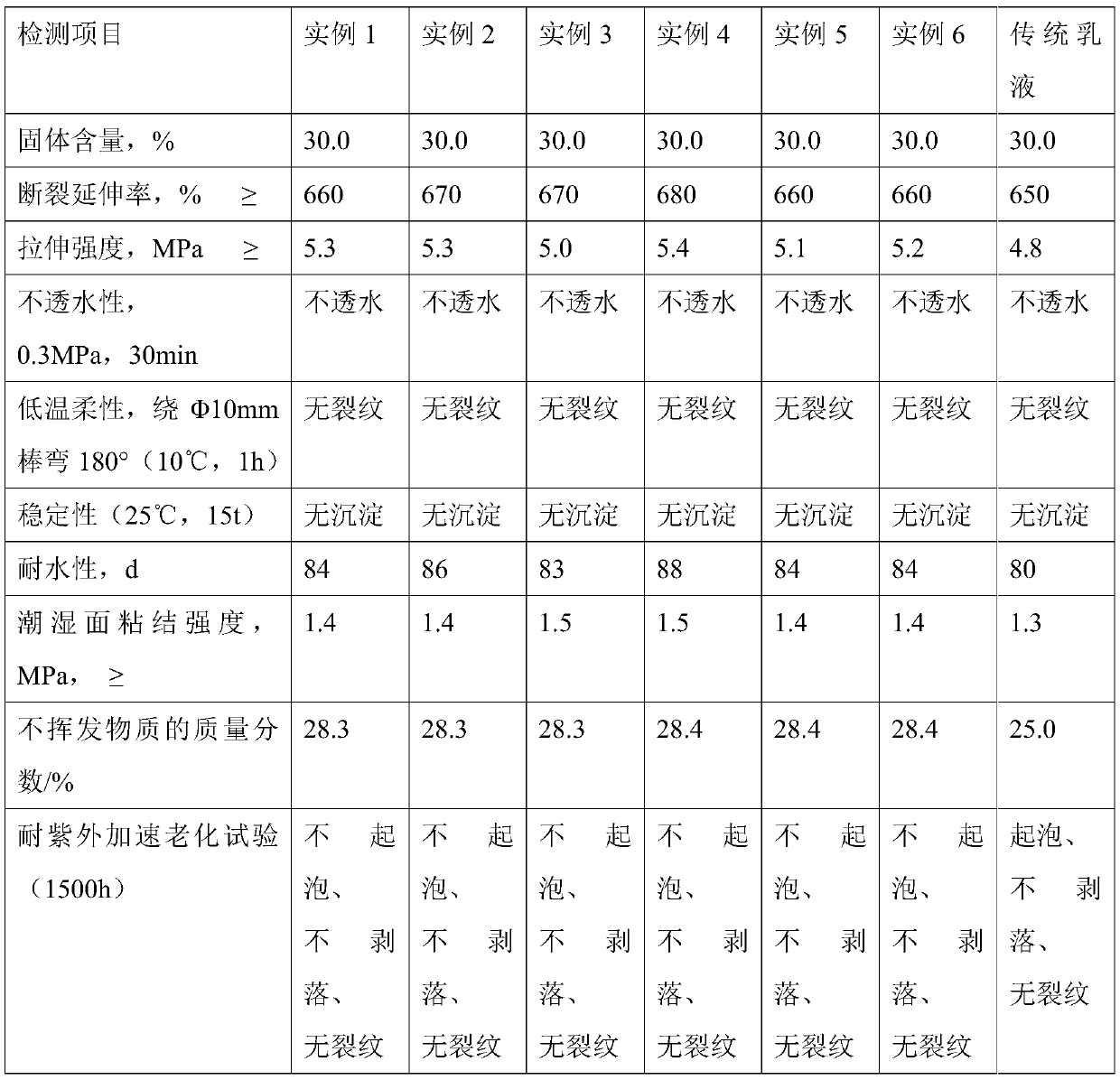

Examples

example 1

[0048] A preparation method of a cationic ester-based soap-free emulsion polymer, which is mainly prepared from the following components:

[0049] Composition with a mass ratio of tetrabutylammonium bisulfate to tetrabutylphosphine fluoride of 2:1: 9 parts

[0050] The composition of octadecyl dimethyl benzyl ammonium chloride and tetrabutyl phosphine acetate with a mass ratio of 4:7: 8 parts

[0051] Sodium methacrylate: 0.5 parts

[0052] Azobisisobutyronitrile: 0.3 parts

[0053] Azobisisoheptanonitrile: 2.7 parts

[0054] Hydroxypropyl acrylate: 12 parts

[0055] Methacryloyloxyethyl hexahydrophthalate monoester: 243 parts

[0056] Hydroxyethyl Phthalic Anhydride Dimethacrylate: 3.2 parts

[0057] Perfluorooctyl ethyl acrylate: 7 parts

[0058] Ethanolamine: 3.3 parts

[0059] Potassium carbonate: 11 parts

[0060] The total mass parts is 1000, and the remainder is water.

[0061] 1) 200 parts of water, 8 parts of a composition with a mass ratio of octadecyldimeth...

example 2

[0066] A preparation method of a cationic ester-based soap-free emulsion polymer, which is mainly prepared from the following components:

[0067] The composition of tetramethylammonium acetate and tetrabutylphosphine fluoride with a mass ratio of 1:1: 12 parts

[0068] The composition of octadecyl dimethyl benzyl ammonium chloride and tetrabutyl phosphine acetate with a mass ratio of 4:1: 12 parts

[0069] Sodium methacrylate: 0.4 parts

[0070] Azobisisobutyronitrile: 0.4 parts

[0071] Azobisisoheptanonitrile: 3.8 parts

[0072] Diethyl maleate: 15 parts

[0073] The composition of n-butyl (meth)acrylate, isobutyl (meth)acrylate, and lauryl (meth)acrylate in a mass ratio of 1:2:3: 218 parts

[0074] Hydroxyethyl Phthalic Anhydride Dimethacrylate: 4.6

[0075] Perfluorooctyl ethyl acrylate: 15 parts

[0076] Triethanolamine: 5.8 parts

[0077] Potassium carbonate: 13 parts

[0078] The total mass parts is 1000, and the remainder is water.

[0079] 1) 200 parts of wa...

example 3

[0084] A preparation method of a cationic ester-based soap-free emulsion polymer, which is mainly prepared from the following components:

[0085] Composition with a mass ratio of tetrabutylammonium bisulfate to tetrabutylphosphine fluoride of 2:1: 7 parts

[0086] The composition of dodecyltrimethylammonium chloride and tetrabutylphosphine acetate with a mass ratio of 1:1: 10 parts

[0087] Sodium methacrylate: 0.8 parts

[0088] Azobisisobutyronitrile: 0.7 parts

[0089] Azobisisoheptanonitrile: 4 parts

[0090] Vinyl acetate: 9 parts

[0091] 2-Propylheptyl acrylate: 232 parts

[0092] Composition of 3:2 mass ratio of hydroxyethyl pyrophthalic anhydride dimethacrylate to di(methacryloyloxyethyl) pyrophthalic anhydride ester: 6.5 parts

[0093] Perfluorooctyl ethyl acrylate: 12 parts

[0094] Ethanolamine: 3 parts

[0095] Potassium hydroxide, sodium carbonate, and sodium bicarbonate in a mass ratio of 2:2:1: 15 parts

[0096] The total mass parts is 1000, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com