Reinforced calcium borosilicate microcrystalline glass composite material and preparation method thereof

A technology of glass-ceramic and composite materials, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of cumbersome process, long production cycle, low degree of crystallization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] A method for preparing the aluminum oxide-reinforced calcium borosilicate glass-ceramic composite plane plate, comprising the following steps:

[0082] 1. Preparation of raw material powder:

[0083] a) CBS glass powder is prepared by melting-water quenching method, which involves weighing and batching according to the formula, dry mixing with a horizontal ball mill for 3-5 hours, and melting with platinum at a melting temperature of 1450-1500 ° C. The holding time or glass The liquid homogenization time is 0.5-2 hours. After the homogenization time is up, the glass liquid is quenched with deionized water, and then ball milled. The ball milling time is 16-24 hours, until the particle size median diameter (D50) of the glass powder=0.5 -2.3μm. image 3 It is the result of DSC (differential scanning calorimetry) analysis of lime borosilicate glass powder. Lime borosilicate glass powder is prepared by melting-water quenching-ball milling method. The median diameter of the...

Embodiment 2

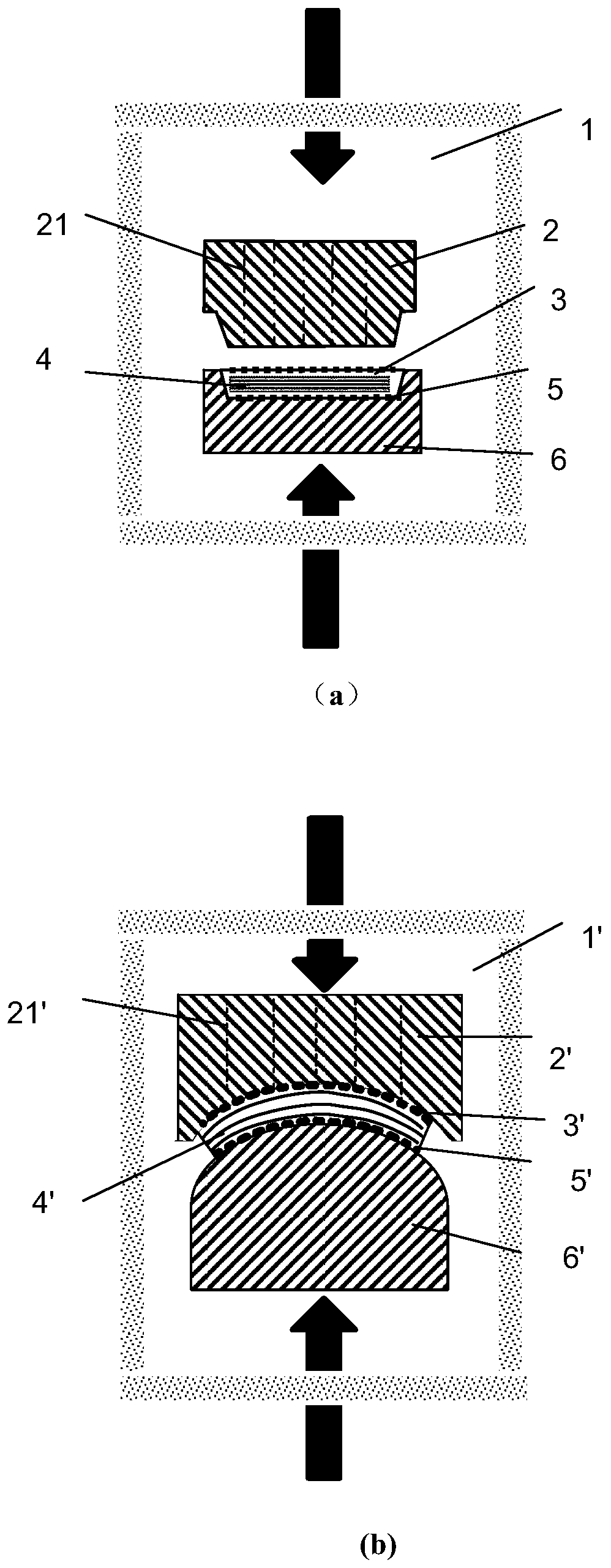

[0105] A preparation method of the alumina-reinforced calcium borosilicate glass-ceramic composite material 3D curved panel, comprising the following steps:

[0106] 1. Preparation of raw material powder:

[0107] a) CBS glass powder is prepared by melting-water quenching method, which involves weighing and batching according to the formula, wherein CaB 2 o 4 Replace 2 / 3 of H 3 BO 3 and a corresponding part of CaCO 3 , Use a corundum-lined horizontal ball mill for dry mixing for 5-10 hours, use a corundum crucible for melting, the melting temperature is 1400-1450°C, the holding time or glass liquid homogenization time is 90-150min, and let the homogenization time The molten glass flows into the water-cooled stainless steel double rollers coated with thermal shock-resistant ceramic coating for rapid cooling and solidification, and then the glass fragments are subjected to dry ball milling for 10-16 hours, and then a horizontal closed Zirconia is stirred and milled until th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com