Synthesis method of micropowder grade cubic boron nitride single crystal

A cubic boron nitride and synthesis method technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve problems such as inability to obtain cBN single crystal, and achieve the effect of complete crystal form and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for synthesizing a micronized cubic boron nitride single crystal, the specific process is as follows:

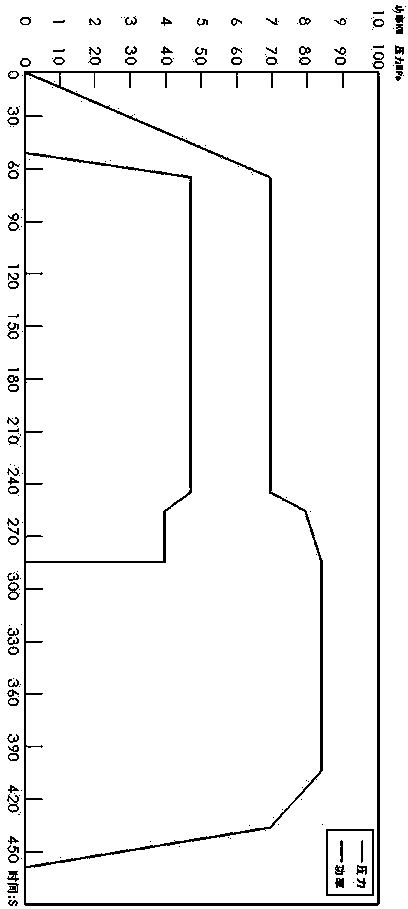

[0022] Fine than 150 mesh Li 3 BN 2 , Li 3 N and NH 4 The powder mixture of Cl is used as the catalyst, and the high-purity and high-crystallinity hBN powder with a purity of 99.5%, a boron oxide content of 0.15%, a graphitization index G.I value of 1.6, and 15 μm is used as a synthetic raw material; Li 3 BN 2 , Li 3 N and NH 4 Cl is mixed at a mass ratio of 10:8:2 to form a catalyst, and the catalyst and hBN are mixed uniformly at a mass ratio of 10:90, and then pressed into a cylinder, put into a graphite heating tube to make a composite rod, and put into six-sided top press In the mechanical synthesis chamber, pressurize at a constant speed for 60s to 70MPa, pause the boost, start heating, set the heating power to 4.8KW, keep it under this pressure and power for 180s, control the nucleation of cubic boron nitride crystals, and continue to boost the p...

Embodiment 2

[0024]A method for synthesizing a micronized cubic boron nitride single crystal, the specific process is as follows:

[0025] Fine than 150 mesh Li 3 BN 2 , Li 3 N and NH 4 The powder mixture of Cl is used as the catalyst, and the high-purity and high-crystallinity hBN powder with a purity of 99.3%, a boron oxide content of 0.13%, a graphitization index G.I value of 1.6, and 12 μm is used as a synthetic raw material; Li 3 BN 2 , Li 3 N and NH 4 Cl is mixed at a mass ratio of 11:7:3 to form a catalyst, and the catalyst and hBN are mixed uniformly at a mass ratio of 15:85, and then pressed into a cylinder, put into a graphite heating tube to make a composite rod, and put into a six-sided top press In the mechanical synthesis chamber, pressurize at a constant speed from 55s to 70MPa, pause the boost, start heating, set the heating power to 4.8KW, keep it under this pressure and power for 180s, control the nucleation of cubic boron nitride crystals, and continue to boost the...

Embodiment 3

[0027] A method for synthesizing a micronized cubic boron nitride single crystal, the specific process is as follows:

[0028] Fine than 150 mesh Li 3 BN 2 , Li 3 N and NH 4 The powder mixture of Cl is used as the catalyst, and the high-purity and high-crystallinity hBN powder with a purity of 99.7%, a boron oxide content of 0.18%, a graphitization index G.I value of 1.6, and 14 μm is used as a synthetic raw material; Li 3 BN 2 , Li 3 N and NH 4 Cl is mixed at a mass ratio of 9:12:4 to form a catalyst, and the catalyst and hBN are mixed uniformly at a mass ratio of 17:83, and then pressed into a cylinder, put into a graphite heating tube to make a synthetic rod, and put into a six-sided top press In the mechanical synthesis chamber, pressurize at a constant speed from 55s to 70MPa, pause the boost, start heating, set the heating power to 4.8KW, keep it under this pressure and power for 180s, control the nucleation of cubic boron nitride crystals, and continue to boost th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com