Controllable preparation method of clay-based microcapsule phase change material

A technology of phase change materials and microcapsules, which is applied in the direction of microcapsule preparation, microsphere preparation, heat exchange materials, etc., can solve the problems of poor mechanical strength, different lengths of polymer chain segments, and large internal stress, etc., and achieve reduction Preparation cost, narrow molecular weight distribution, and effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0028] Weigh 3 g of hexadecane, 2 g of butyl acrylate, 1 g of ethylene glycol dimethacrylate, 0.02 g of ethyl α-bromophenylacetate, and 0.01 g of triethylamine / syringe red Y to form an organic phase ;Weigh 0.15g of attapulgite clay of ≥200 mesh and add it to 10g of deionized water, and ultrasonically disperse to form a water phase; mix the organic phase and water phase in a transparent reaction vessel with a mass ratio of 5:10, and emulsify at high speed On-board emulsification forms a stable emulsion. Seal the transparent reaction container and transfer it to a photopolymerization device, and polymerize for 2 h; after the polymerization, unseal and centrifuge to obtain a white powdery solid, wash the powder with ethanol several times and centrifuge, and open the obtained solid powder at room temperature The mouth was dried to constant weight to obtain the attapulgite clay-based microcapsule phase change material.

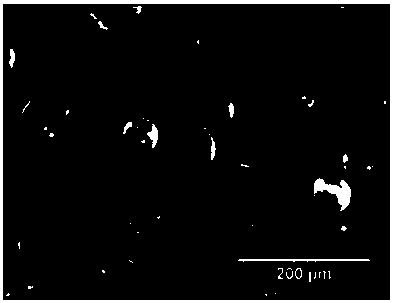

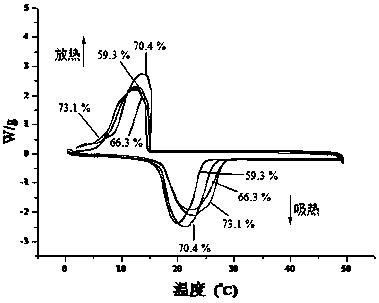

[0029] Such as figure 1 SEM image of the attapulgite / acryli...

Embodiment approach 2

[0032] Weigh 2 g of eicosane, 2 g of methyl acrylate, 1 g of trimethylolpropane trimethacrylate as a crosslinking agent, 0.01 g of ethyl 2-bromoisobutyrate, and 0.005 g of triethylamine / fluorescein Dissolve together to form an organic phase; weigh 0.2 g of kaolin ≥ 200 mesh and add it to 10 g of deionized water, and ultrasonically disperse to form an aqueous phase; mix the organic phase and the aqueous phase in a transparent reaction vessel at a mass ratio of 2:7, and Emulsify on a high-speed emulsifier to form a stable emulsion. Seal the transparent reaction container and transfer it to a photopolymerization device, and polymerize for 3 h; after the polymerization, unseal and centrifuge to obtain a white powdery solid, wash the powder with ethanol several times and centrifuge, and vacuum the obtained solid powder at room temperature Dry to constant weight to obtain kaolin-based microcapsule phase change material.

Embodiment approach 3

[0034] Weigh 4 g of docosane, 2 g of octadecyl acrylate, 1 g of trimethylolpropane trimethacrylate as a crosslinking agent, 0.015 g of 2-bromopropionitrile, and 0.0025 g of triethylamine / rhodamine 6G in Form an organic phase together; weigh 0.5 g of montmorillonite ≥ 200 mesh and add it to 10 g of deionized water, and ultrasonically disperse to form an aqueous phase; mix the organic phase and the aqueous phase in a transparent reaction vessel at a mass ratio of 5:7, and Emulsify on a high-speed emulsifier to form a stable emulsion. Seal the transparent reaction vessel, transfer it to a photopolymerization device, and polymerize for 5 h; after the polymerization, unseal and centrifuge to obtain a white powdery solid, wash the powder with ethanol several times and centrifuge, and vacuum the obtained solid powder at room temperature Dry to constant weight to obtain the montmorillonite-based microcapsule phase change material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com