Heating film material with PTC effect and preparation method thereof

A technology for heating films and film materials, applied in heating element materials, ohmic resistance heating, electric heating devices, etc., can solve the problems of local temperature rise, uneven mixing, unstable performance, etc., and achieve adjustable temperature coefficient and simple method. Ease of implementation and increased controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] One aspect of the embodiments of the present invention provides a method for preparing a heating film material with PTC effect, comprising the following steps:

[0021] The conductive material and the PTC additive are respectively mixed with the solvent to form the conductive material dispersion and the PTC additive dispersion;

[0022] uniformly mixing the conductive material dispersion with the PTC additive dispersion to form a mixed solution;

[0023] removing the solvent in the mixed solution to obtain PTC-coated conductive material particles;

[0024] calcining the PTC-coated conductive material particles in an inert atmosphere at 300-500° C. for 1-3 hours to obtain a PTC-coated conductive material;

[0025] preparing the PTC-coated conductive material with polymer resin, solvent, dispersant and coupling agent to form a uniform slurry;

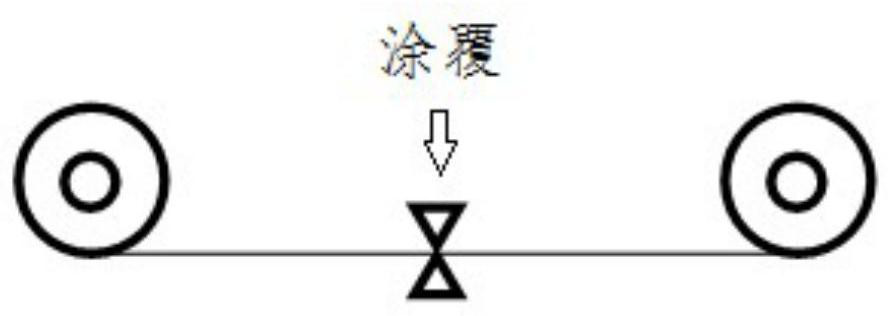

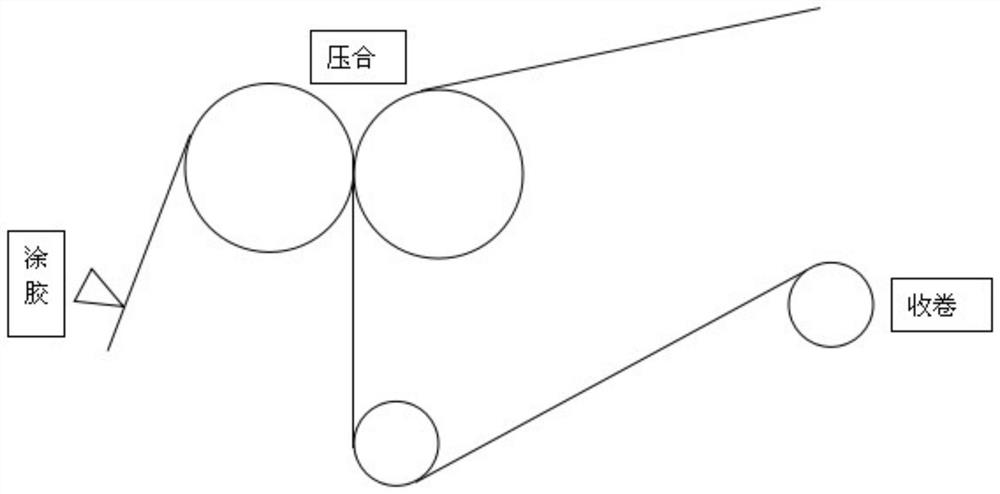

[0026] The slurry is formed into a film material and compounded with a base film.

[0027] Further, the PTC-coated conductive ...

Embodiment 1

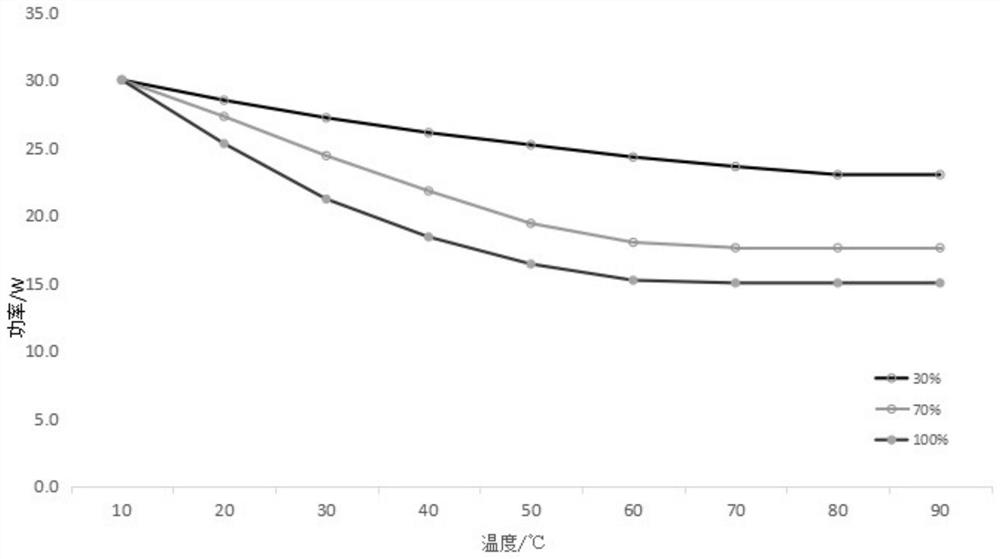

[0059] 10 parts of carbon nanotubes (if not otherwise specified below, they are all parts by weight), 1.5 parts of dispersant KV01, 0.5 parts of surfactant LAS, and 38 parts of ethanol are fully ground, stirred and dispersed to make a 20wt% dispersion; 5 parts of nano-SiO 2 , 5 parts BaTiO 3 Powder, 1.5 parts of dispersant KV01, 0.5 part of surfactant LAS, and 88 parts of ethanol were fully ground, stirred and dispersed to make a 10wt% dispersion; then 100 parts of each of the two dispersions were mixed, and 0.5 part of surface active After mixing uniformly, the solution volatilized to form PTC-coated conductive material particles with a conductive material of 66 wt%, which was ground and calcined at 300-500 °C for 1-3 hours in a nitrogen atmosphere to form PTC-coated conductive material for use. 10 parts of PTC coated conductive material, 2 parts of dispersant KV01, 1 part of KH560 silane coupling agent, 30 parts of ethanol are fully ground, stirred and dispersed, and then m...

Embodiment 2

[0062] By fully grinding, stirring and dispersing 8 parts of graphene, 1.4 parts of dispersant KV01, 0.6 parts of surfactant LAS, and 40 parts of ethanol to make a 16wt% dispersion; 4 parts nano TiO 2 , 4 parts BaTiO 3 Powder, 1.5 parts of dispersant KV01, 0.5 parts of surfactant LAS, and 90 parts of ethanol were fully ground, stirred and dispersed to make a dispersion liquid of 8wt%; then 100 parts of each of the two dispersion liquids were mixed, and 0.5 part of surface active agent was added After mixing uniformly, the solution volatilized to form PTC-coated conductive material particles with a conductive material of 62 wt%, which was ground and calcined at 300-400°C for 1-3 hours in an inert atmosphere to form PTC-coated conductive material for use. 15 parts of PTC coated conductive material, 2.5 parts of dispersant KV01, 0.5 part of KH560 silane coupling agent, and 30 parts of ethanol are fully ground, stirred and dispersed, and then mixed with 52 parts of polyester resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com