Laser shock gray cast iron component surface micro-texturing method

A surface micro-modeling and laser shock technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of high cost and complex manufacturing process, improve wear resistance, good controllability, and avoid direct contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

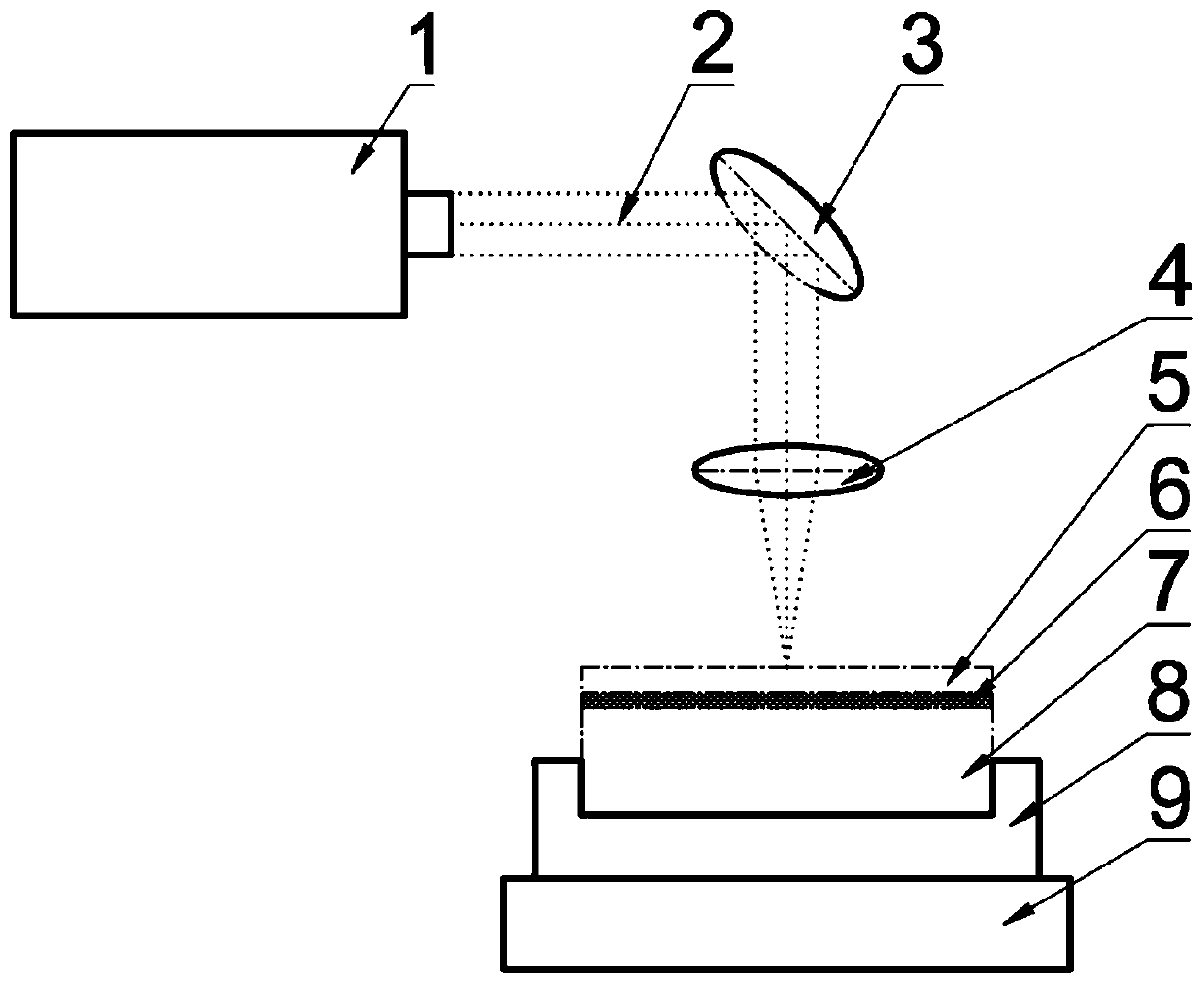

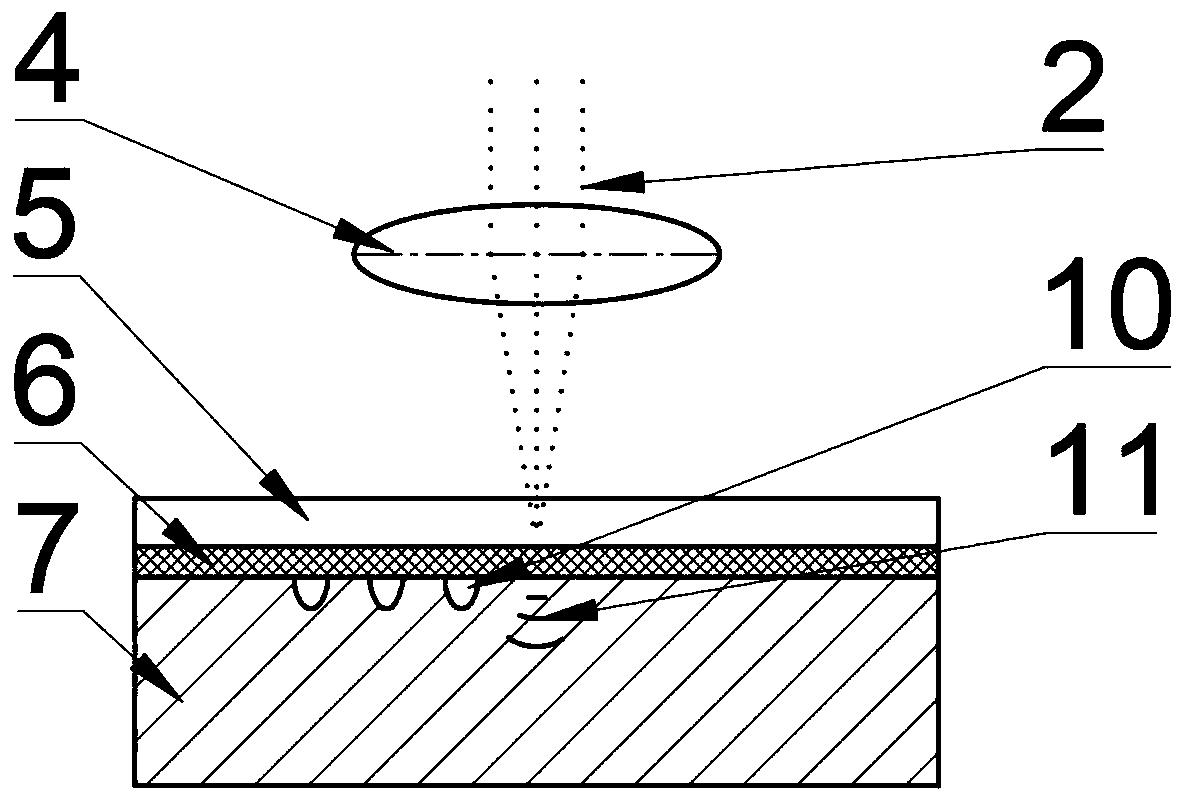

[0024] Such as figure 1 and figure 2 As shown, the gray cast iron component 7 is fixed on the numerical control workbench 9 through the clamp 8; the laser 1 emits the laser beam 2, and the horizontal optical path is converted into a longitudinal optical path through the reflector 3, and the focusing lens 4 passes through the constrained layer water 5, Focusing on the aluminum foil 6 of the energy absorbing layer, the shock wave 11 is transmitted to the interior of the gray cast iron component 7 for strengthening. The pressure of the shock wave 11 is much greater than the dynamic yield strength of the gray cast iron component 7, causing plastic deformation on the surface of the gray cast iron component 7 to form pits 10; By controlling the movement of the numerical control workbench 9 , the arrayed pits 10 are processed on the gray cast iron component 7 .

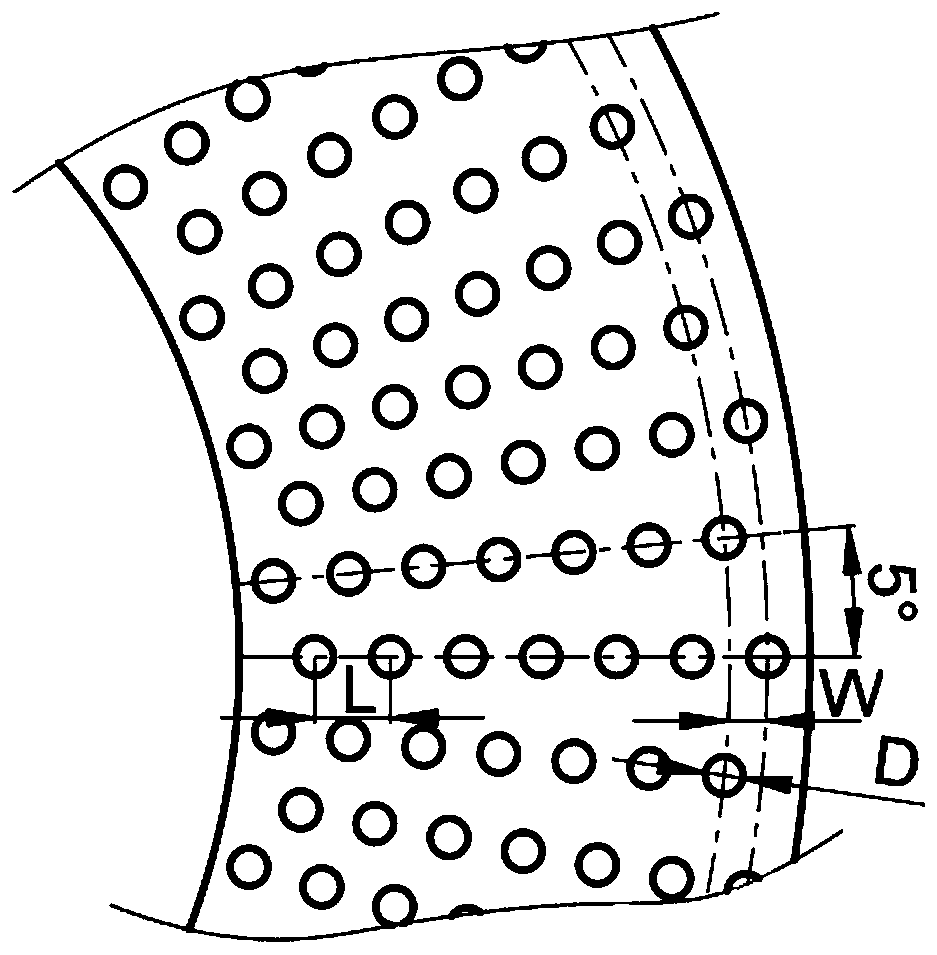

[0025] A kind of method (taking the brake disc as example) of laser shock gray cast iron component surface micromodeling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com