Colorless transparent polyimide film

A technology of transparent polyimide and polyimide film, applied in the field of functional films, can solve the problems of limited comprehensive performance improvement, low refractive index and high birefringence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

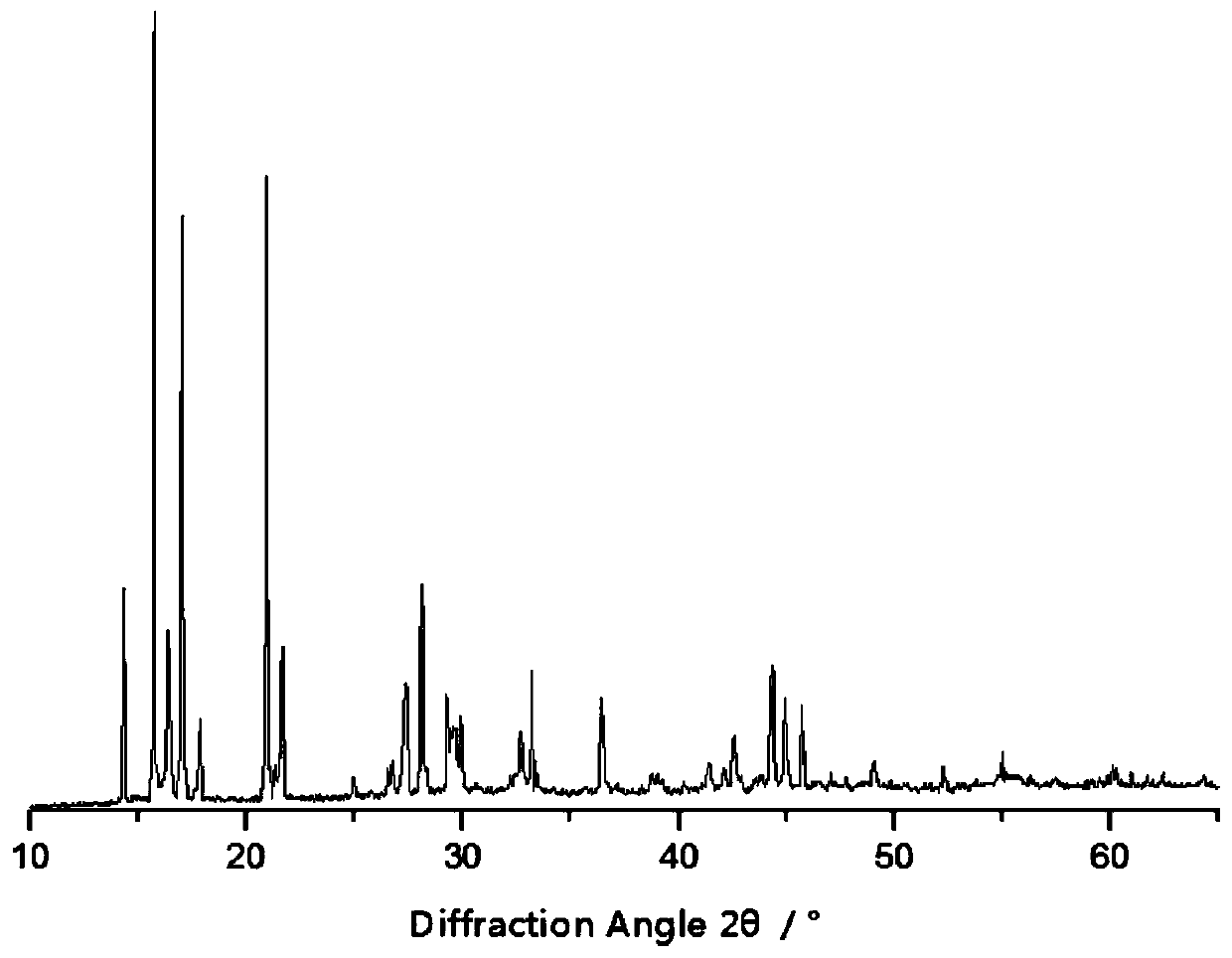

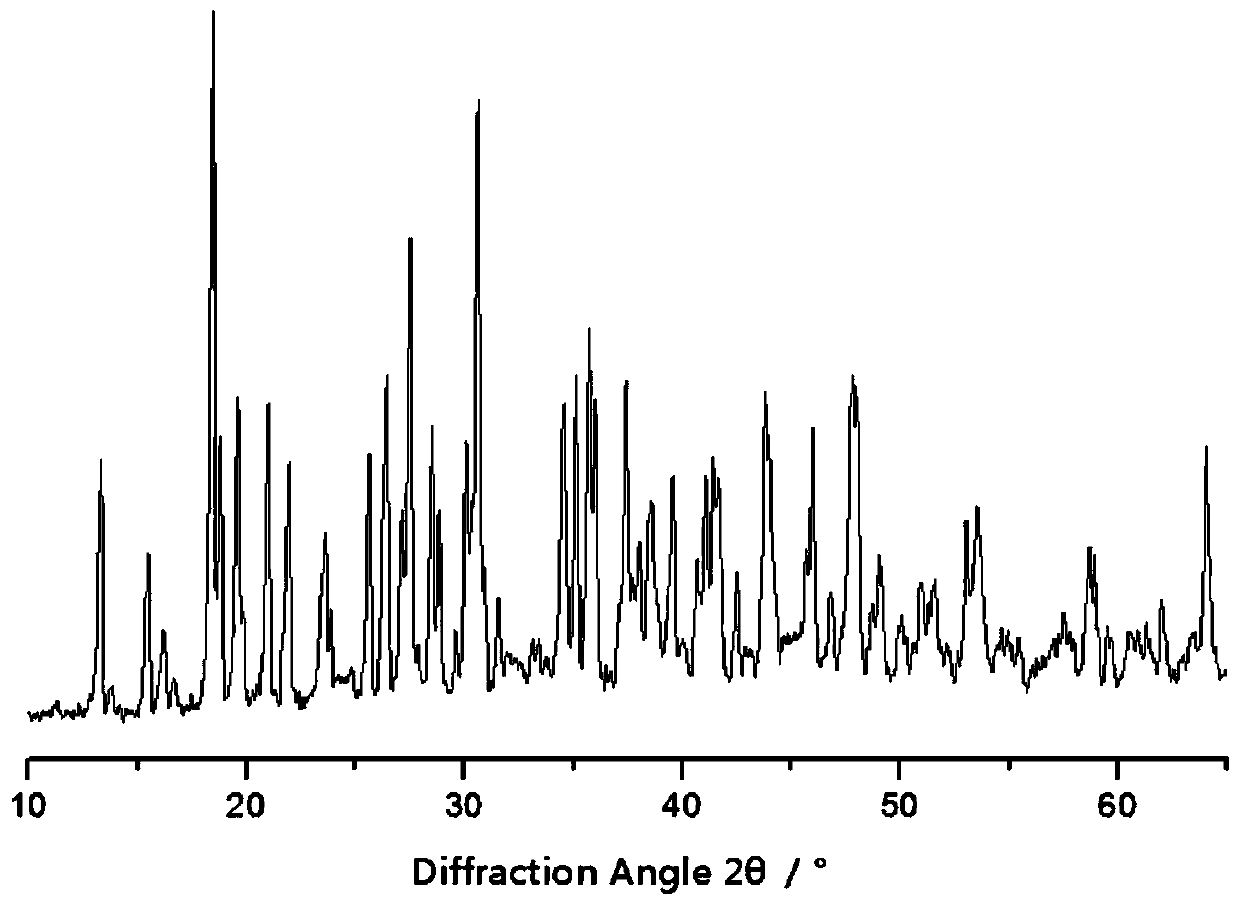

Image

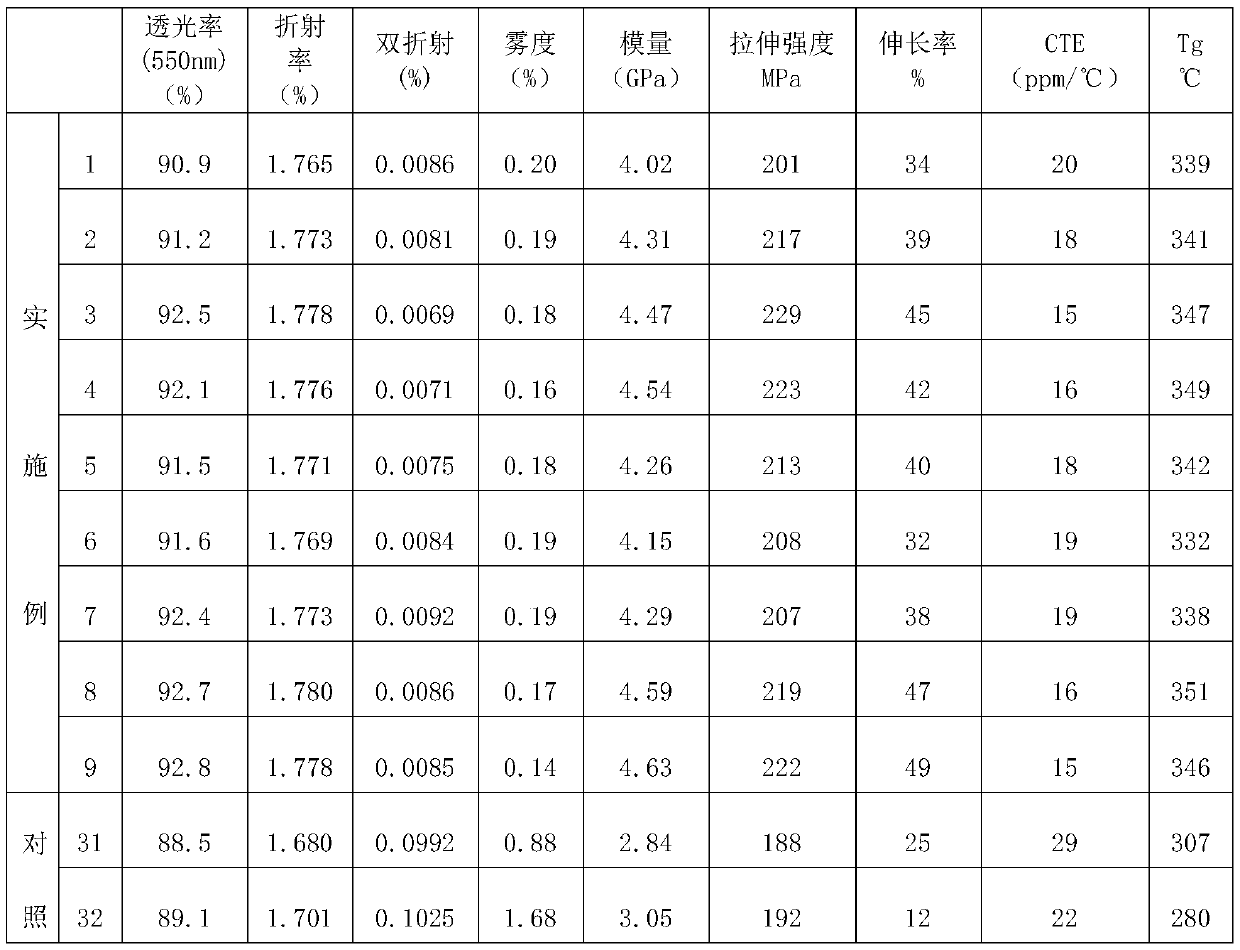

Examples

Embodiment 1

[0047] Ⅰ. Preparation of polyamic acid resin solution containing nitrate inorganic filler

[0048] In a nitrogen atmosphere, control the temperature of the synthesis system at 15°C, add 1.50kg of diamine 2,2'-bis(trifluoromethyl)-4 to 33.12kg of N,N'-dimethylacetamide (DMAC) solvent, 4'-Diaminobiphenyl (2,2'-TFDB) was stirred and dissolved. After 2,2'-TFDB was completely dissolved, 1.38 kg of dianhydride 3 with a diamine molar ratio of 1:1 was added in 10 times at a uniform speed. , 3',4,4'-biphenyltetracarboxylic dianhydride (s-BPDA), and stirred at 1500r / min, synthesized by polycondensation reaction for 24 hours to obtain a solid content M = 2.88kg, that is, the solid content ratio is 8wt% Polyamic acid resin solution;

[0049] Keep the polymerized polyamic acid resin solution system at 15°C and directly add 0.00288kg (0.1wt%) zinc nitrate inorganic filler powder with a pH value of 4.8, which has been pretreated at 98°C for 10h, to the polyamic acid resin solution for co-po...

Embodiment 2

[0054] The difference between this example and Example 1 is that "keep the polymerized polyamic acid resin solution system at 15°C and directly add 0.00576kg (0.2wt%) of nitric acid with a pH value of 4.8 that has been pretreated at 98°C for 10 hours. Add zinc inorganic filler powder to polyamic acid resin solution for blending".

Embodiment 3

[0056] The difference between this example and Example 1 is that "keep the polymerized polyamic acid resin solution system at 15°C and directly add 0.00864kg (0.3wt%) of nitric acid with a pH value of 4.8 that has been pretreated at 98°C for 10 hours. Add zinc inorganic filler powder to polyamic acid resin solution for blending".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com