Application of MXene/silane surface composite silane film in metal corrosion protection

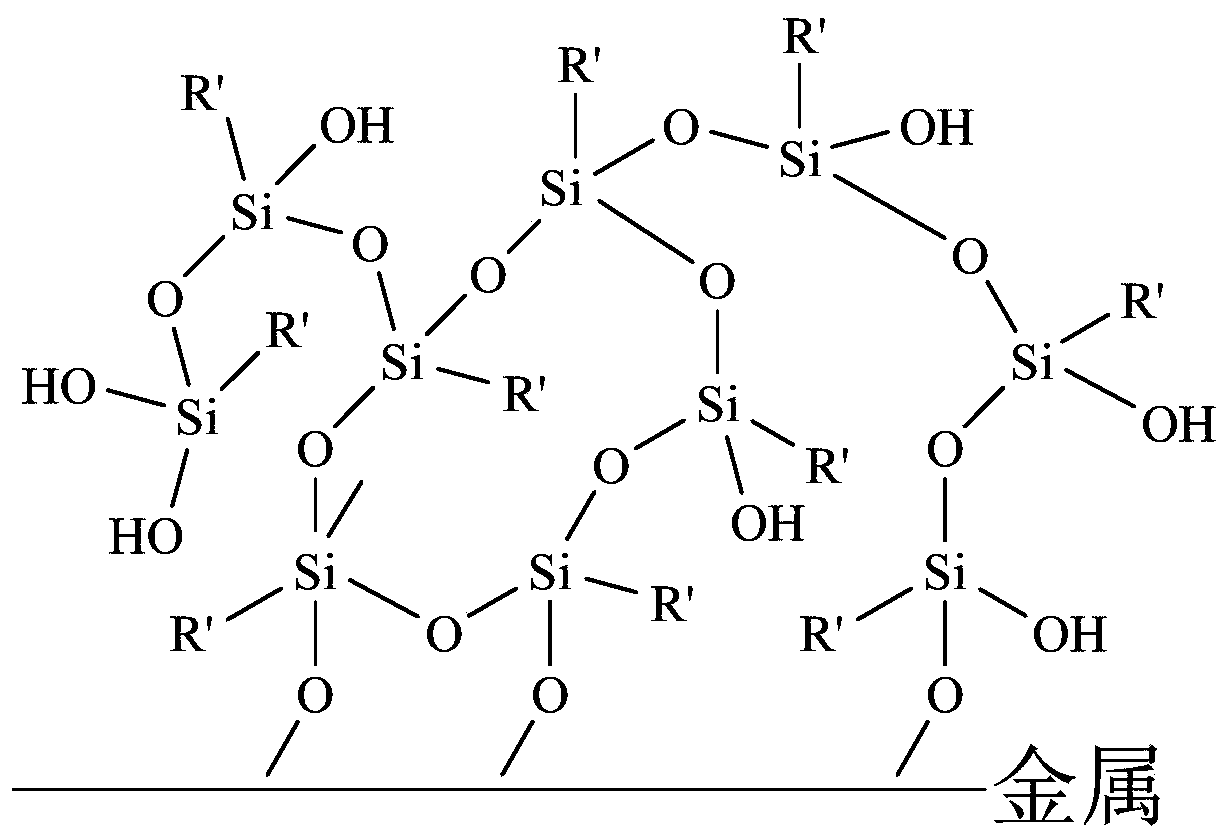

A composite silane film, metal corrosion technology, applied in the direction of metal material coating process, etc., can solve problems such as hindering the diffusion of corrosive medium, and achieve the effects of being conducive to industrialized amplification, wide source of raw materials, and simple process operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

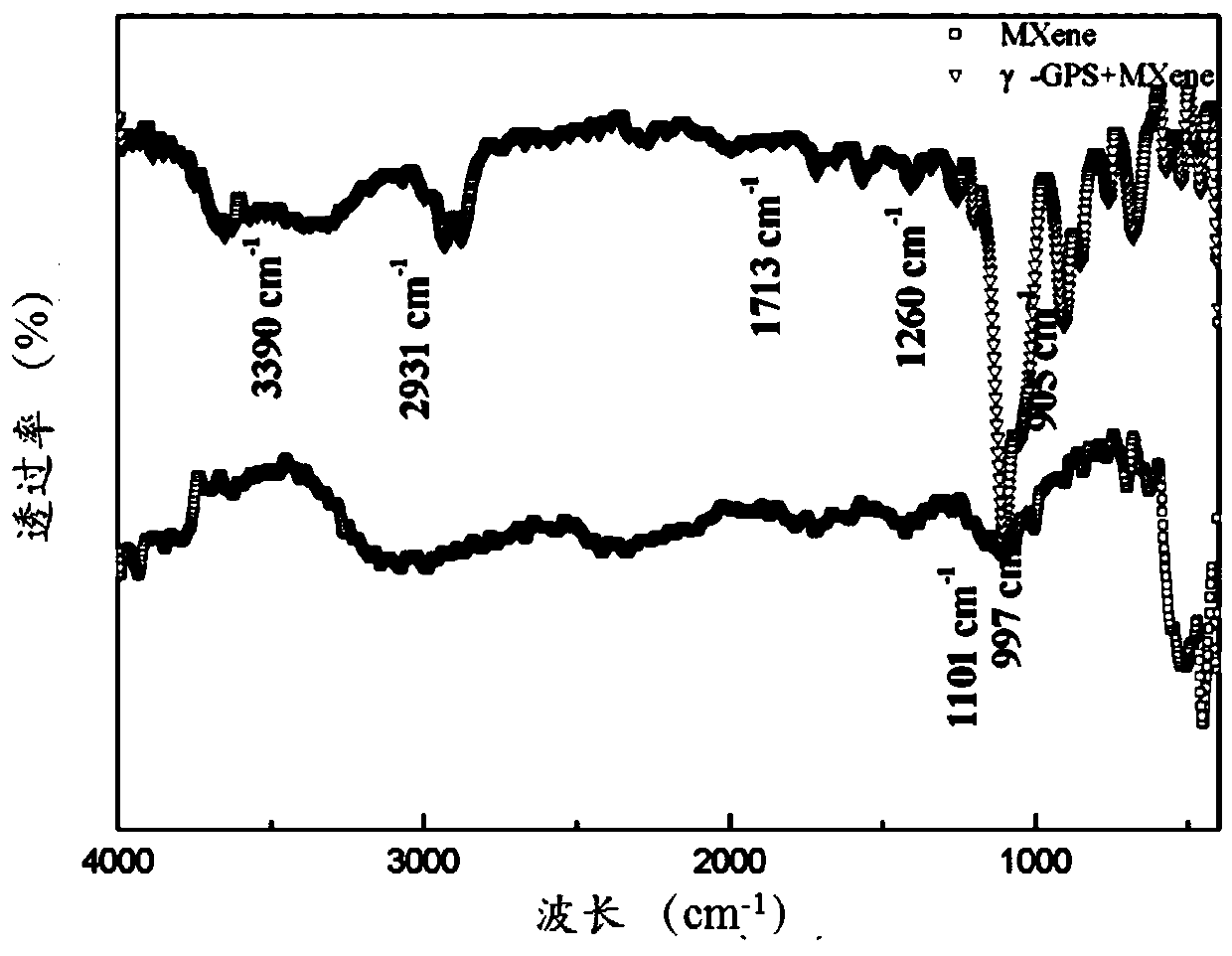

[0055] First configure a 1% concentration of γ-GPS silane solution, wherein γ-GPS / water / ethanol is 1 / 5 / 94 (v / v / v), take a certain amount of MXene and γ-GPS silane solution, stir the solution to control The concentration of MXene was 1 mg / mL, the pH was adjusted to 4.5 with acetic acid, and ultrasonic hydrolysis was performed at 35 °C for 2 h. The size of the aluminum alloy is cut into 10mm×10mm×1mm, and polished step by step with 800#, 1000#, 1500#, 2000# water-grinding sandpaper, and then polished to a mirror surface with 1.0μm aluminum oxide abrasive paste on a velvet polishing cloth, and then After washing with 3wt% NaOH at room temperature for 30s, take it out, rinse it with a large amount of deionized water and dry it with a hair dryer, then immerse the sample in the prepared silane hydrolyzate for 1min and repeat 3 times, take it out and blow off the excess liquid, and put it in an oven at 120°C After 120 minutes of curing to form a film, a composite silane film can be o...

Embodiment 2

[0057] First configure a 5% concentration of BTSE silane solution, wherein BTSE / water / ethanol is 1 / 5 / 94 (v / v / v), take a certain amount of MXene and BTSE silane solution to mix, stir the solution to control the concentration of MXene to 1mg / mL, adjusted the pH to 4.5 with acetic acid, and ultrasonically hydrolyzed at 35°C for 2h. The size of the aluminum alloy is cut into 10mm×10mm×1mm, and polished step by step with 800#, 1000#, 1500#, 2000# water-grinding sandpaper, and then polished to a mirror surface with 1.0μm aluminum oxide abrasive paste on a velvet polishing cloth, and then After washing with 3wt% NaOH at room temperature for 30s, take it out, rinse it with a large amount of deionized water and dry it with a hair dryer, then immerse the sample in the prepared silane hydrolyzate for 1min and repeat 3 times, take it out and blow off the excess liquid, and put it in an oven at 120°C After 120 minutes of curing to form a film, a composite silane film can be obtained.

Embodiment 3

[0059] First configure a 5% concentration of BTSE silane solution, wherein BTSE / water / ethanol is 1 / 5 / 94 (v / v / v), take a certain amount of MXene and BTSE silane solution to mix, stir the solution to control the concentration of MXene to 1mg / mL, adjusted the pH to 4.5 with acetic acid, and ultrasonically hydrolyzed at 35°C for 2h. Q235 steel was polished step by step with 800#, 1000#, 1500#, and 2000# water-grinding sandpaper, and then polished to a mirror surface with 1.0 μm alumina abrasive paste on a velvet polishing cloth, and then washed with 3wt% NaOH at room temperature for 30 seconds, and then removed Finally, rinse with a large amount of deionized water and blow dry with a hair dryer, then immerse the sample in the prepared silane hydrolyzate for 1min and repeat 3 times, take it out and blow off the excess liquid, put it in an oven at 120°C for 120min to solidify and form a film, and then you can get a composite silane membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Amplitude | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com