Method for producing particle board from chrome-containing leather shavings

A technology of particle board and chrome leather shavings, which is applied in the field of chromium-containing leather shavings to make particle boards, can solve the problems of inability to realize resource utilization of chromium-containing leather shavings, market capacity limitations, etc., and increase benzene rings, carbon sources, and processing costs Low, easy to collect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

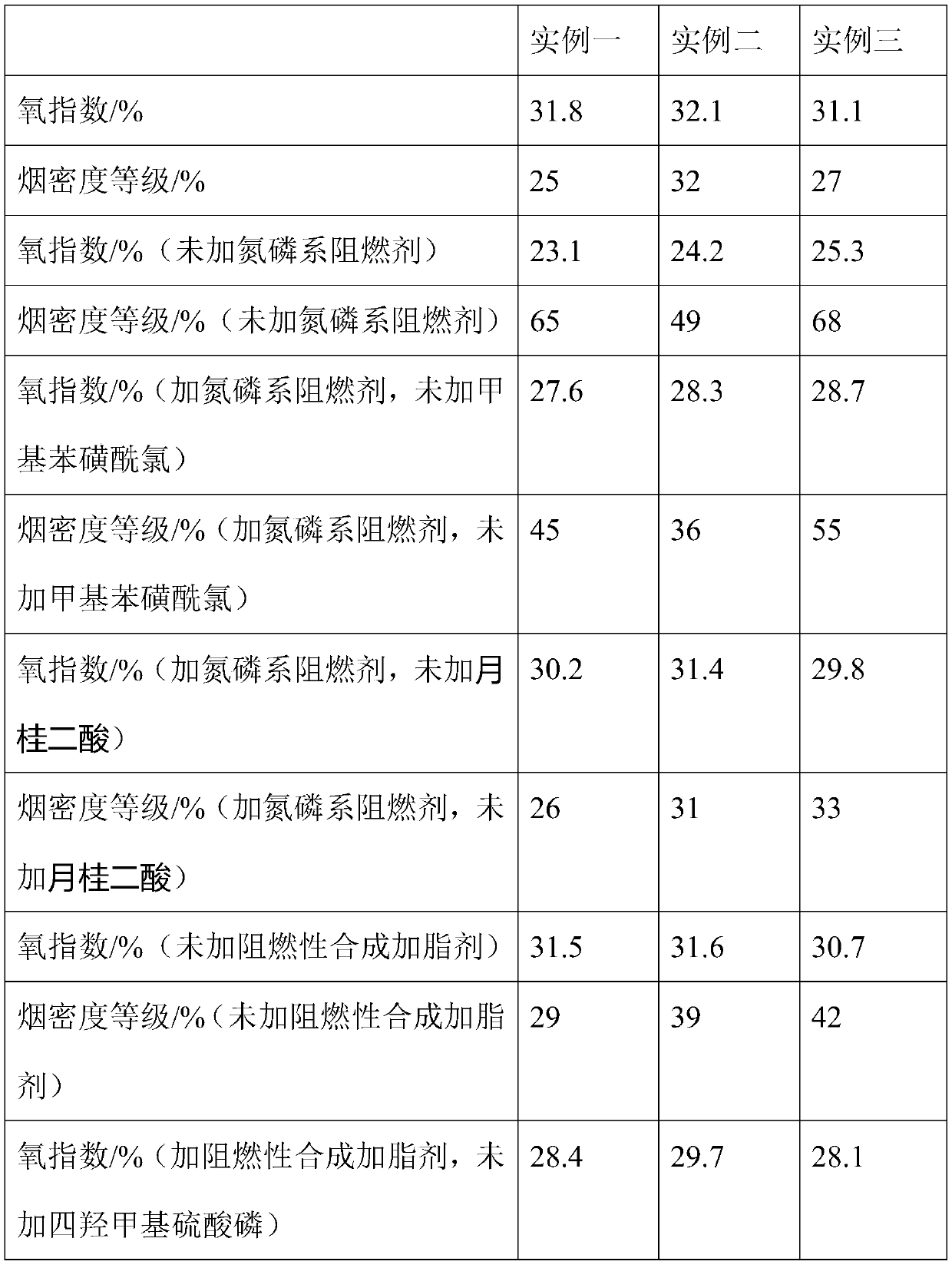

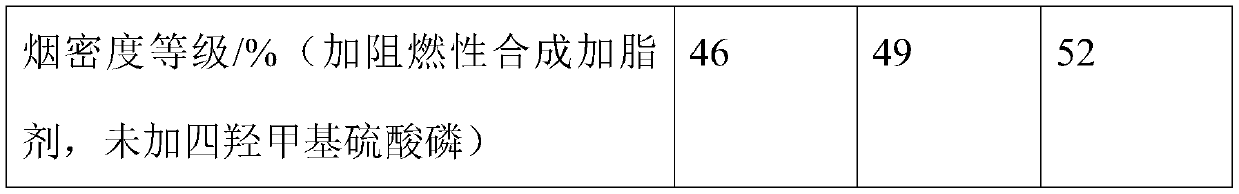

preparation example 1

[0038] (1) Mix 60g of blue leather shavings, 1g of oxalic acid and 90g of water evenly, stir at 35°C for 1h; then adjust the pH to 4, add 0.4g of sodium citrate dihydrate, stir for 30min, and dry the obtained blue chrome shavings Dry;

[0039] (2), all the blue leather shavings of step (1), polyurethane glue 700w13.2g, nitrogen-phosphorus flame retardant 2g, nitrile rubber toughening agent 1g, sodium p-vinylbenzenesulfonate toughening synergist 0.2g , flame retardant synthetic fatliquoring agent 5g, water expansion inhibitor 0.9g, n-butyl benzoic acid 0.7g, water-based transparent waterproofing agent WP01 0.2g (Hangzhou Ruijiang New Material Technology Co., Ltd.) mixed evenly, and placed at room temperature for 30min , put it on a 4mm thick mold, the pressure of the flat vulcanizing machine is 10Mpa, the temperature is 90°C, heat and pressurize in the flat vulcanizing machine, the processing time is 30min, the obtained plate is placed in a constant temperature and humidity box...

preparation example 2

[0045] (1) Mix 60g of blue leather shavings, 3g of oxalic acid and 90g of water evenly, stir at 40°C for 2h; then adjust the pH to 4.5, add 0.7g of sodium citrate dihydrate, stir for 60min, and dry the obtained blue chrome shavings Dry;

[0046] (2), all blue leather shavings of step (1), universal glue 899 (Guangdong Gujia Industrial Co., Ltd.) 21.1g, nitrogen-phosphorus flame retardant 8g, polyvinyl butyral toughening agent 3g, malonic acid ring (sub- ) isopropyl ester toughening synergist 0.5g, flame retardant synthetic fatliquoring agent 7g, water swelling inhibitor 2.1g, trimethylolpropane 2.5g, water-based transparent waterproofing agent WP01 is 0.6g (Hangzhou Ruijiang New Material Technology Co., Ltd.) mixed evenly, placed at room temperature for 60 minutes, put it on a 4mm thick mold, the pressure of the flat vulcanizer is 12Mpa, the temperature is 100°C, heated and pressurized in the flat vulcanizer, the processing time is 60min, and the obtained plate is placed in I...

preparation example 3

[0052] (1) Mix 60g of blue leather shavings, 2g of oxalic acid and 90g of water evenly, and stir at 40°C for 1.5h; then adjust the pH to 4, add 0.55g of sodium citrate dihydrate, stir for 45min, and mix the obtained blue chrome shavings drying;

[0053] (2), all the blue leather scraps in step (1), polyurethane glue 700w17.2g, nitrogen phosphorus flame retardant 5g, polyvinyl butyral toughening agent 2g, 3,4-dimethylaniline toughening synergist 0.35g, 6g of flame-retardant synthetic fatliquoring agent, 1.5g of water swelling inhibitor, 1.6g of cinnamic amide, 0.4g of water-based transparent waterproofing agent WP01 (Hangzhou Ruijiang New Material Technology Co., Ltd.), mix well, and place at room temperature for 45min. Put it on a 4mm thick mold, the pressure of the flat vulcanizer is 11Mpa, the temperature is 95°C, heat and pressurize in the flat vulcanizer, the processing time is 45min, put the obtained plate in a constant temperature and humidity box for 48h, control the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com