Waste asphalt pavement material separation and regeneration treatment system and processing technology thereof

A technology for waste asphalt and pavement materials, applied in the field of old asphalt treatment, can solve the problems of increasing the unit price of stone materials, hidden dangers of transportation safety, insufficient independent innovation, etc., and achieve the effect of reducing waste accumulation sites, improving utilization efficiency, and expanding application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

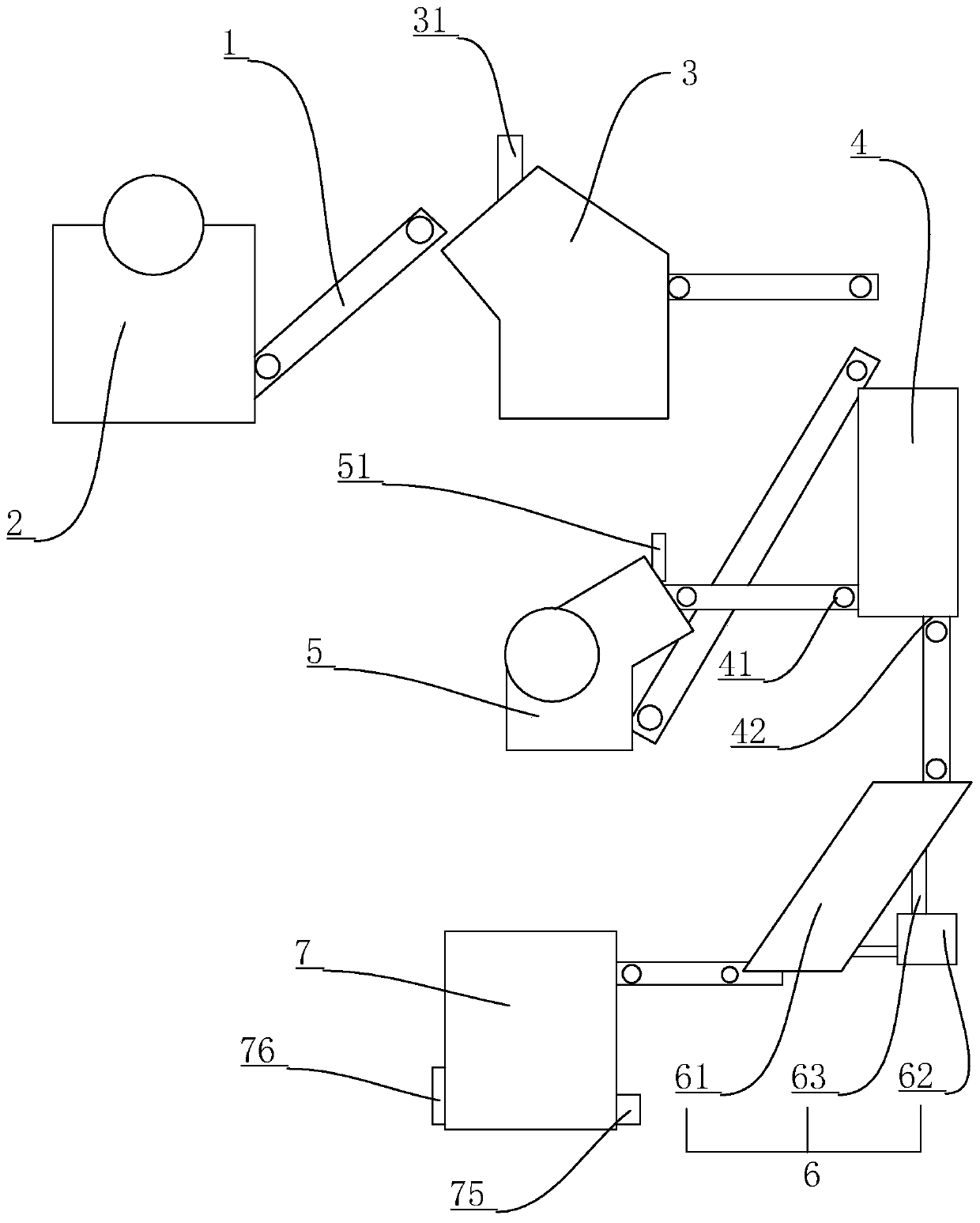

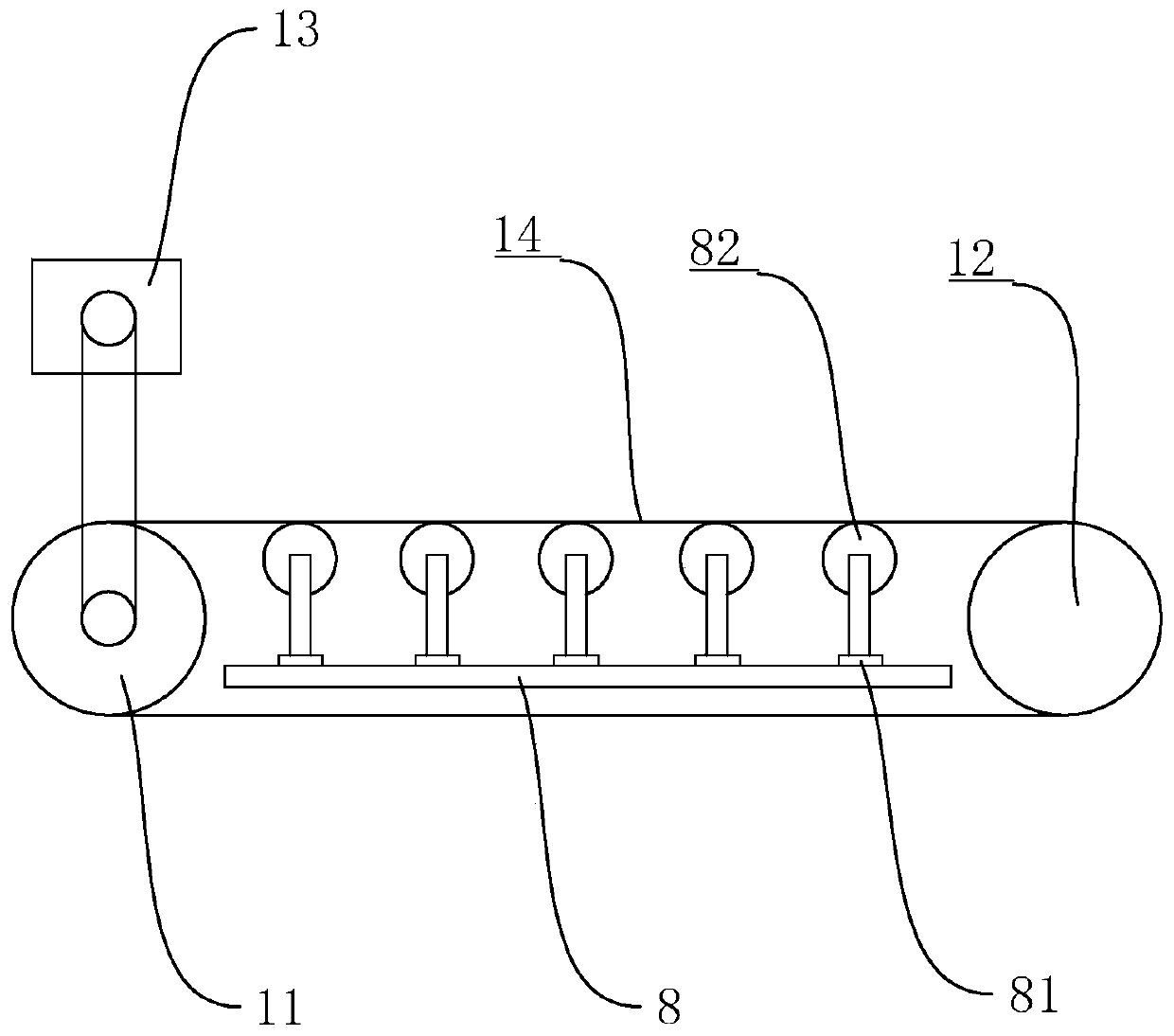

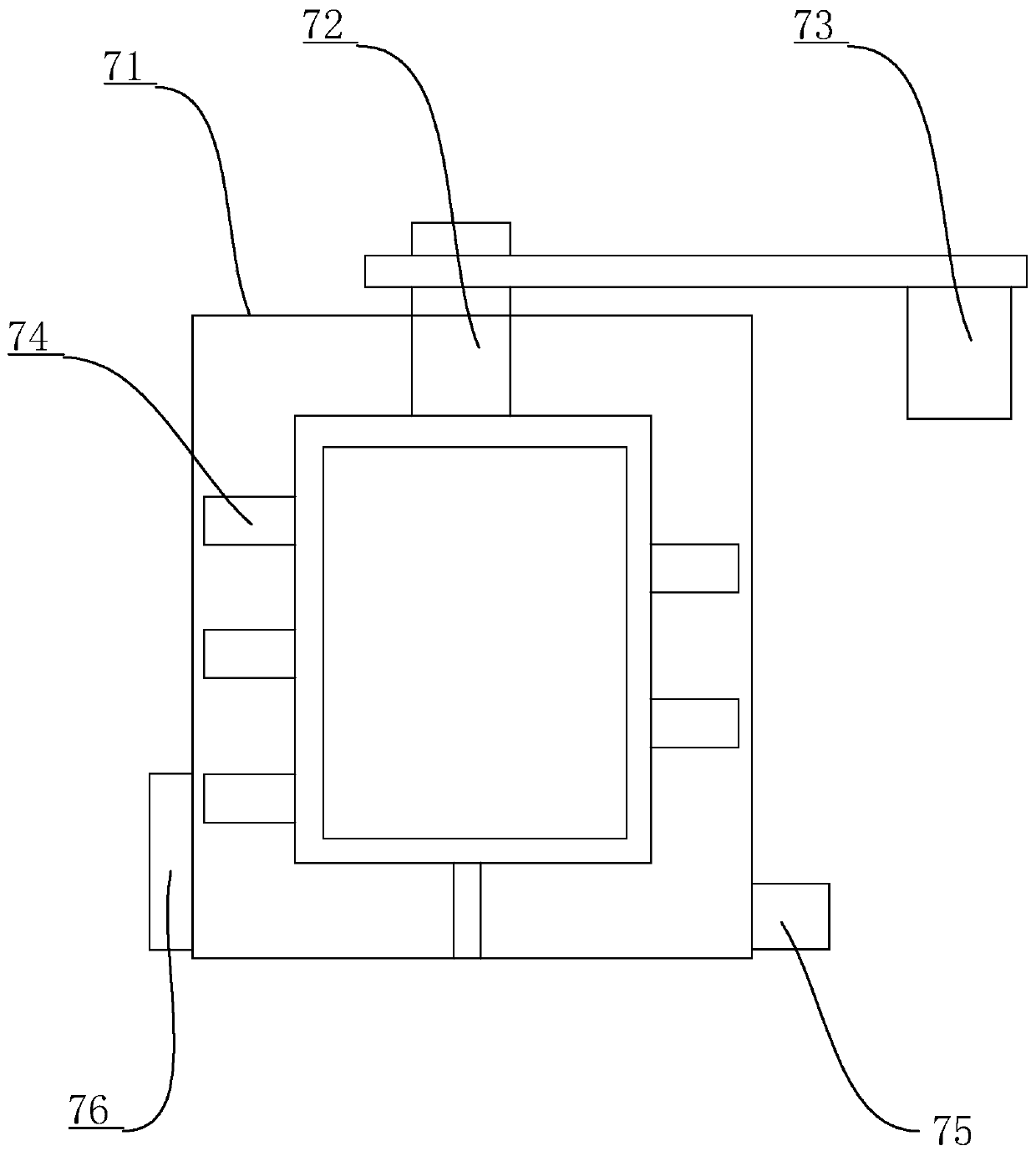

[0051] A waste asphalt pavement material separation regeneration treatment system and its processing technology, refer to figure 1 , figure 2 and image 3 , which includes:

[0052] Conveying device 1, conveying device 1 comprises driving roller 11, driven roller 12, the drive motor 13 that drives driving roller 11 to rotate and the transmission belt 14 that interference is set on the outer surface of driving roller 11 and driven roller 12, conveying device 1 Used to convey waste asphalt pavement materials;

[0053] Crushing equipment 2, the crushing equipment 2 is a jaw crusher, and the jaw crusher is an existing technology. During the crushing process of the jaw crusher, the asphalt in the waste asphalt pavement material will not soften, and the crushed waste asphalt The temperature of the pavement material will not change, and the primary crushing work through the jaw crusher has a good crushing effect;

[0054] Coarse stripping equipment 3, rough stripping equipment 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com