Temperature stable type high temperature ceramic capacitor medium material, and preparation method thereof

A capacitor dielectric and temperature stable technology, applied in fixed capacitor dielectrics, fixed capacitors, capacitors, etc., can solve problems such as human health and ecological environment hazards, and achieve the effects of low cost, low dielectric loss, and good high-temperature application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

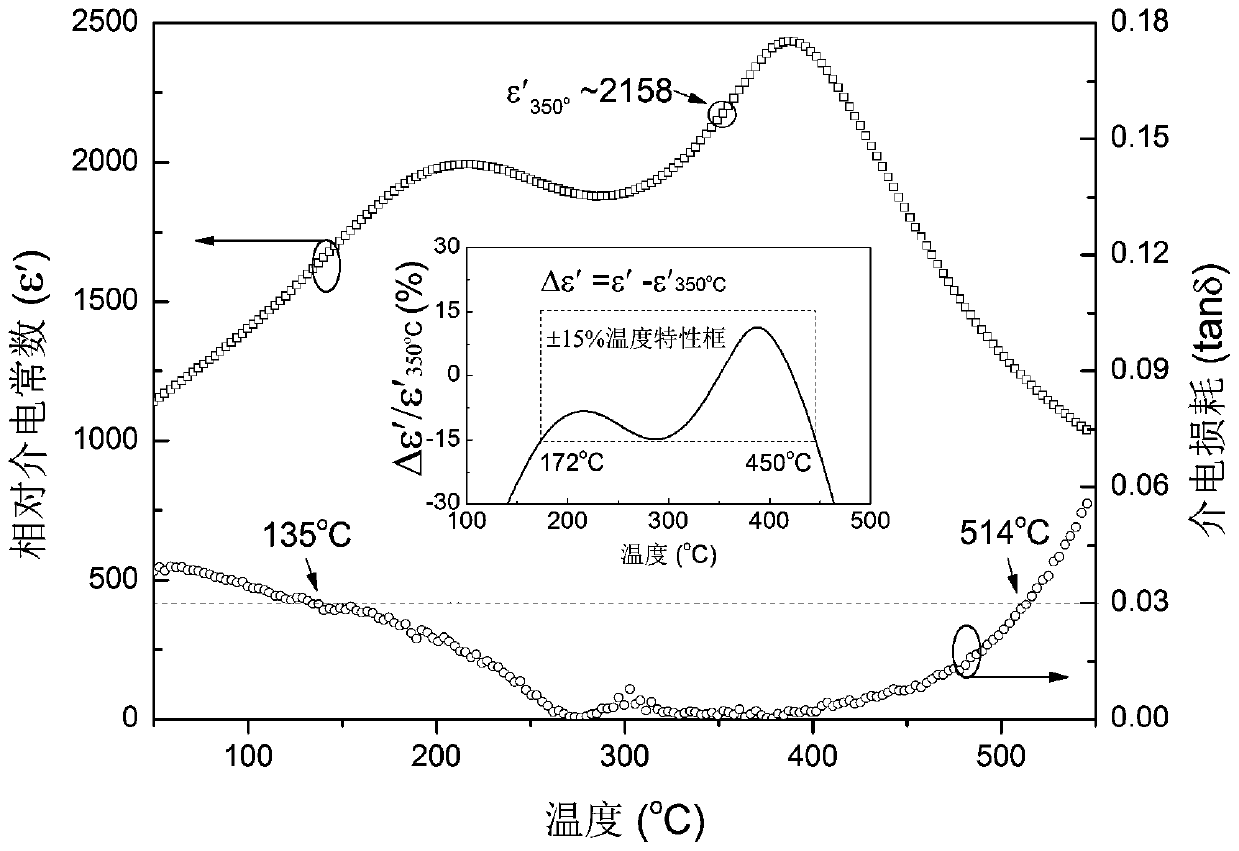

[0019] The chemical composition formula of the temperature-stable high-temperature ceramic capacitor dielectric material provided by the present invention is: 0.995 (K 0.5 Na 0.5 )NbO 3 -0.005 LaBiO 3 .

[0020] The specific steps for preparing the above-mentioned temperature-stable high-temperature ceramic capacitor dielectric material are as follows:

[0021] (1) High-purity powder K with a purity greater than 99% 2 CO 3 、Na 2 CO 3 , Nb 2 o 5 , La 2 o 3 and Bi 2 o 3 As a starting material, put it in an oven at 120°C for 10 hours, and after drying, according to 0.995 (K 0.5 Na 0.5 )NbO 3 -0.005 LaBiO 3 The stoichiometric ratio is accurately weighed (accurate to 4 decimal places); put the weighed raw material powder into a nylon ball mill jar and use absolute ethanol and zirconia balls as ball milling media on a planetary ball mill at 360 rpm Minute speed ball milling for 6 hours to obtain uniformly mixed slurry A; place the uniformly mixed slurry A in a watch...

Embodiment 2

[0024] The chemical composition formula of the temperature-stable high-temperature ceramic capacitor dielectric material provided by the present invention is: 0.995 (K 0.5 Na 0.5 )NbO 3 -0.005 LaBiO 3 .

[0025] The specific steps for preparing the above-mentioned temperature-stable high-temperature ceramic capacitor dielectric material are as follows:

[0026] (1) High-purity powder K with a purity greater than 99% 2 CO 3 、Na 2 CO 3 , Nb 2 o 5 , La 2 o 3 and Bi 2 o 3 As a starting material, put it in an oven at 120°C for 24 hours, and after drying, according to 0.995 (K 0.5 Na 0.5 )NbO 3 -0.005 LaBiO 3 The stoichiometric ratio is accurately weighed (4 digits after the decimal point); put the weighed raw material powder into a nylon ball mill jar and use absolute ethanol and zirconia balls as ball milling media on a planetary ball mill at 360 rpm Speed ball milling for 8 hours to obtain uniformly mixed slurry A; place the uniformly mixed slurry A in a watch ...

Embodiment 3

[0029] The chemical composition formula of the temperature-stable high-temperature ceramic capacitor dielectric material provided by the present invention is: 0.995 (K 0.5 Na 0.5 )NbO 3 -0.005 LaBiO 3 .

[0030] The specific steps for preparing the above-mentioned temperature-stable high-temperature ceramic capacitor dielectric material are as follows:

[0031] (1) High-purity powder K with a purity greater than 99% 2 CO 3 、Na 2 CO 3 , Nb 2 o 5 , La 2 o 3 and Bi 2 o 3 As a starting material, put it in an oven at 120°C for 10 hours, and after drying, according to 0.995 (K 0.5 Na 0.5 )NbO 3 -0.005 LaBiO 3 The stoichiometric ratio is accurately weighed (accurate to 4 decimal places); put the weighed raw material powder into a nylon ball mill jar and use absolute ethanol and zirconia balls as ball milling media on a planetary ball mill at 360 rpm Milling at a speed of 10 minutes for 10 hours to obtain uniformly mixed slurry A; place the uniformly mixed slurry A in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com