Preparation method of surface composite coating for bottom plate of reduction furnace

A technology of surface compounding and reduction furnace, applied in the direction of coating, superimposed layer plating, metal material coating process, etc., can solve the problems of limited reduction furnace stable production, difficulty of reducing furnace chassis coating, loss of protection effect, etc. Achieve the effect of reducing the cost of raw materials, avoiding polysilicon pollution, and not easy to bulge and fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a composite coating on the surface of a reduction furnace chassis, comprising the following steps:

[0039] (1) Surface treatment: Grind the surface of the reduction furnace chassis with 800# sandpaper, then clean it with acetone, and finally dry the chassis surface with compressed air to remove grease and other impurities on the chassis surface;

[0040](2) The diameter of the reduction furnace chassis is 1.8m, and supporting protective fixtures and spraying auxiliary equipment are installed to ensure that the reduction furnace chassis is not damaged and polluted during the coating preparation process;

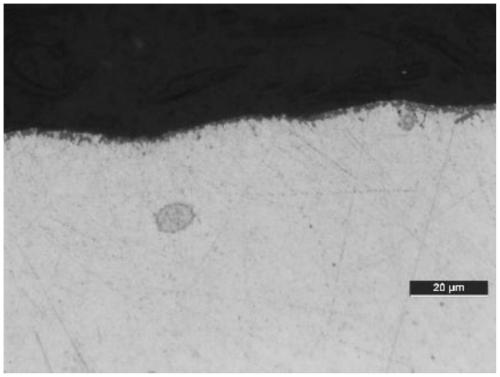

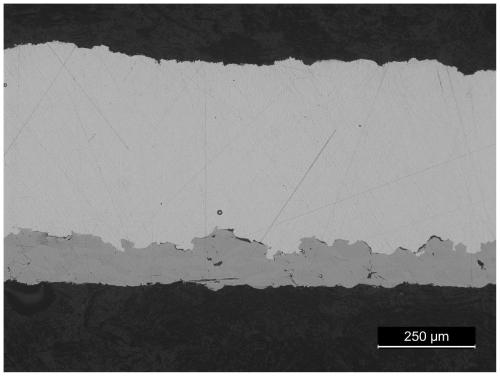

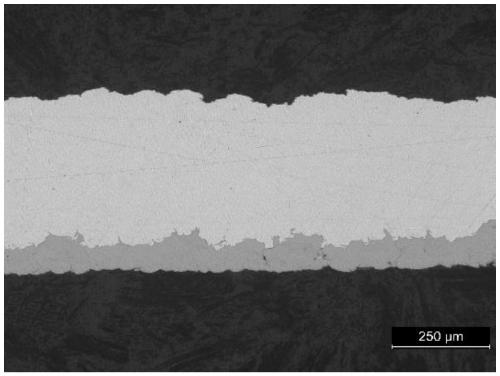

[0041] (3) Supersonic flame spraying is used to prepare a layer of bonding layer on the surface of the chassis that has been treated; the thickness of the bonding layer is 2 μm, the porosity is less than 1%, and the bonding strength> 35MPa; the raw material of the bonding layer is Ni powder, the average particle size of the raw material is 20μm, ...

Embodiment 2

[0047] A method for preparing a composite coating on the surface of a reduction furnace chassis, comprising the following steps:

[0048] (1) Surface treatment: Grind the surface of the reduction furnace chassis with 800# sandpaper, then clean it with acetone, and finally dry the chassis surface with compressed air to remove grease and other impurities on the chassis surface;

[0049] (2) The diameter of the reduction furnace chassis is 1.8m, and supporting protective fixtures and spraying auxiliary equipment are installed to ensure that the reduction furnace chassis is not damaged and polluted during the coating preparation process;

[0050] (3) adopt supersonic flame spraying to prepare one layer of bonding layer on the chassis surface that has done surface treatment; Bonding layer thickness is 50 μ m, porosity is less than 1%, bonding strength>35MPa; The raw material of described bonding layer is NiCr powder, the average particle size of the raw material is 150 μm, and the ...

Embodiment 3

[0056] A method for preparing a composite coating on the surface of a reduction furnace chassis, comprising the following steps:

[0057] (1) Surface treatment: Grind the surface of the reduction furnace chassis with 800# sandpaper, then clean it with acetone, and finally dry the chassis surface with compressed air to remove grease and other impurities on the chassis surface;

[0058] (2) The diameter of the reduction furnace chassis is 1.8m, and supporting protective fixtures and spraying auxiliary equipment are installed to ensure that the reduction furnace chassis is not damaged and polluted during the coating preparation process;

[0059] (3) Supersonic flame spraying is used to prepare a layer of adhesive layer on the surface of the surface treated chassis; the thickness of the adhesive layer is 1000 μm, the porosity is less than 1%, and the bonding strength> 35MPa; the raw material of the adhesive layer is Ti powder, the average particle size of the raw material is 250 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com