A kind of preparation method of w-cu continuous gradient composite material

A composite material and gradient technology, which is applied in the field of preparation of W-Cu continuous gradient composite materials, can solve the problems affecting the application of W-Cu continuous gradient composite materials, difficult to obtain W-Cu composite materials, high raw material requirements, and high cost Low, simple equipment, simple equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

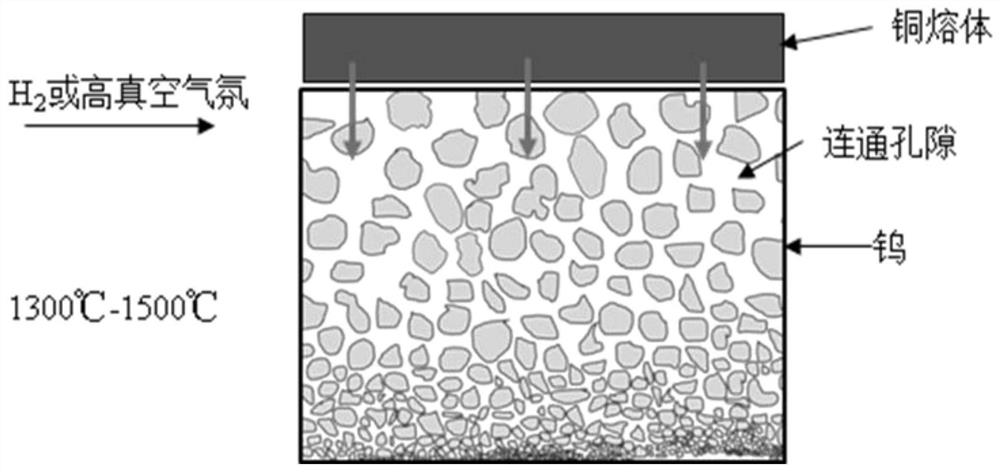

[0032] Example 1: Preparation of W-Cu continuous gradient composites with different binder content slurries

[0033] (1) According to the mass ratio of 1:1:1:1, 50g of W powders with different particle sizes (0.8μm, 1.2μm, 2μm and 4.5μm) were weighed respectively, and different contents of (2%, 3%, 4%, 5 %) polyvinyl butyral (PVB), placed in a mixing tank and mixed in a light mixer for 2 hours to obtain a mixed powder. Take out the mixed powder obtained and pour it into a ball mill jar, add polyethylene glycol 400 and dibutyl phthalate with the same content as PVB, then add 41g of absolute ethanol, add 200g of cemented carbide balls, ball mill for 12 hours, and rotate at a speed of 300r / min. The obtained slurry was kept at a constant temperature of 25° C. to allow the W in the slurry to settle, and at the same time, the solvent was volatilized and dried during and after the settling process to obtain a green body.

[0034] (2) The obtained blank is deglued at 350°C, and the...

Embodiment 2

[0038] Example 2: Preparation of W-Cu continuous gradient composite material at different sintering temperatures

[0039] In this example, the W-Cu continuous gradient composite material was prepared according to the same method as sample 3 in Example 1, the only difference being that the sintering temperatures in step (2) were 1000°C, 1200°C, 1500°C, and 1800°C respectively, and the obtained samples Labeled in order as Sample A, Sample B, Sample C, and Sample D.

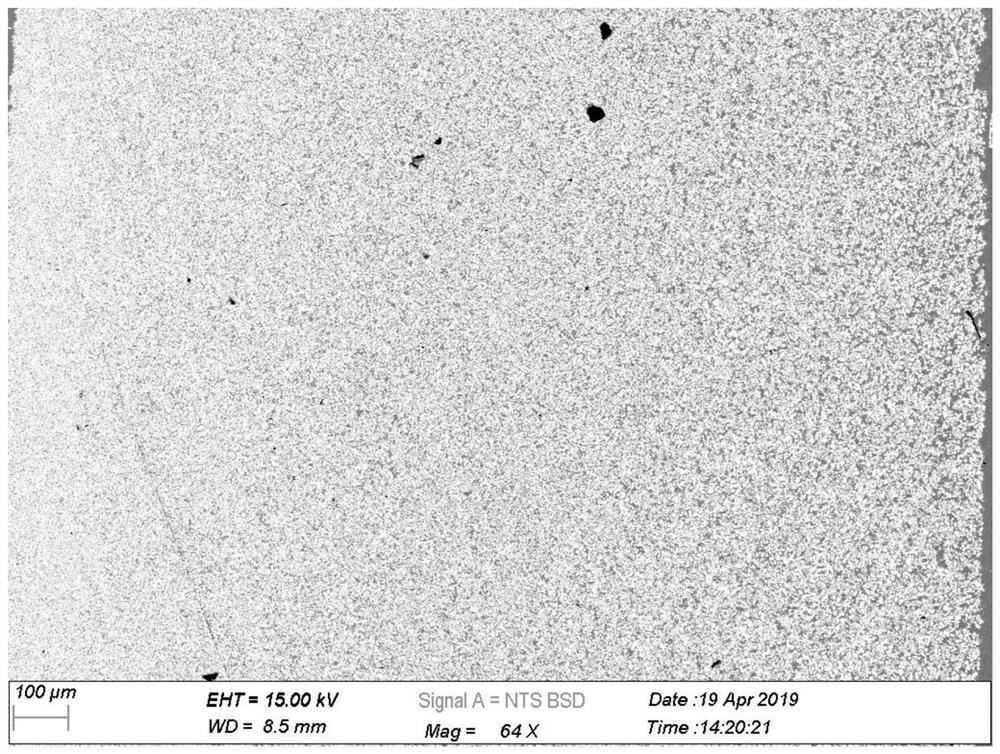

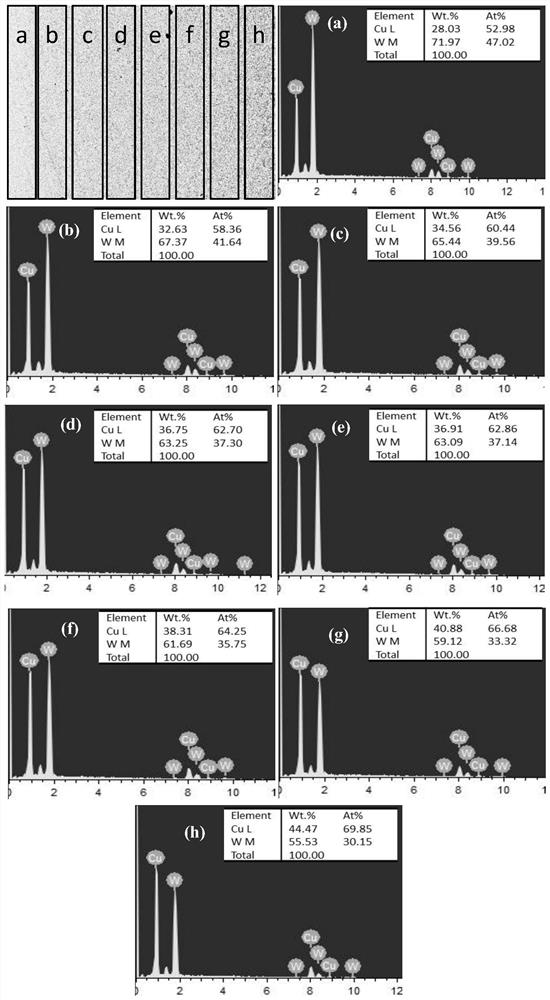

[0040] Field emission observation and EDS energy spectrum characterization were carried out on the morphology of the obtained samples. The results showed that each sample had a dense structure, Cu was distributed in a continuous gradient, and the continuity was good. And the Cu content distribution along the cross section of sample A, sample B, sample C, and sample D is 28.03wt% ~ 44.47wt%, 15.23wt% ~ 34.2wt%, 8.32wt% ~ 28.0wt% and 0wt% ~ 25.33wt% %. It can be seen that by adjusting the sintering temperature of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com