One-step synthesis method of tetragonal zirconium dioxide by means of water-assisted diethylene glycol

A technology of diethylene glycol and zirconia, applied in the field of nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1: Measure 3ml of water and 7ml of diethylene glycol, stir well and add 2.15g of zirconium nitrate pentahydrate; prepare 5ml of 5mol / L sodium hydroxide solution;

[0022] Step 2: Under stirring conditions, mix the two solutions prepared above, continue to stir for 15 minutes to make the reaction system uniform, move to a 25ml polytetrafluoroethylene-lined stainless steel reaction kettle, seal it and place it in an oven at 180°C for 8 hours ; Step 3: Wash the reaction product 2-3 times with water, 2 times with alcohol, and dry at 40°C for 10 hours.

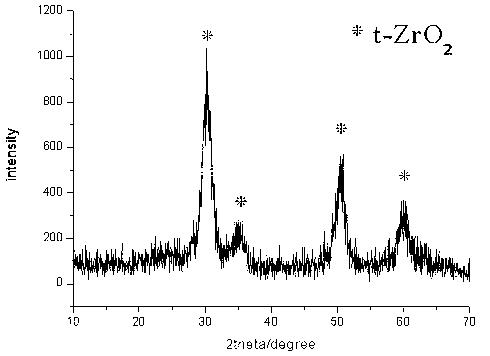

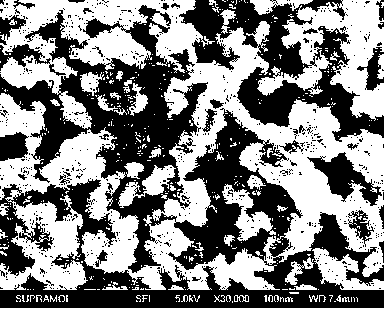

[0023] Obtain high-purity tetragonal self-stabilized zirconia nanoparticles with a particle size of about 50nm. like figure 1 It is the X-ray diffraction spectrum of the product tetragonal phase zirconia nanoparticles, and the particle size is calculated to be about 50nm through computer simulation. figure 2 It is a scanning electron micrograph of the product tetragonal phase zirconia, as shown in the figure, the par...

Embodiment 2

[0025] Step 1: Measure 3ml of water and 7ml of diethylene glycol, stir well and add 2.15g of zirconium nitrate pentahydrate; prepare 7.5ml of 5mol / L sodium hydroxide solution;

[0026] Step 2: with embodiment 1 step 2;

[0027] Step 3: same as embodiment 1 step 3;

[0028] Obtain high-purity tetragonal self-stabilized zirconia nanoparticles with a particle size of about 50nm.

Embodiment 3

[0030] Step 1: Measure 3ml of water, 7ml of diethylene glycol, stir evenly and add 1.61g of zirconium oxychloride octahydrate; prepare 5ml of 5mol / L sodium hydroxide solution;

[0031] Step 2: with embodiment 1 step 2;

[0032] Step 3: same as embodiment 1 step 3;

[0033] Obtain high-purity tetragonal self-stabilized zirconia nanoparticles with a particle size of about 50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com