A kind of high stability polyvinyl chloride recovery emulsion and preparation method thereof

A polyvinyl chloride, high-stability technology, applied in the field of polymer material modification, can solve the problems of easy delamination, low stability of PVC emulsion, slow coagulation speed, etc., to change the dispersion performance, break through the technical bottleneck, and expand the application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

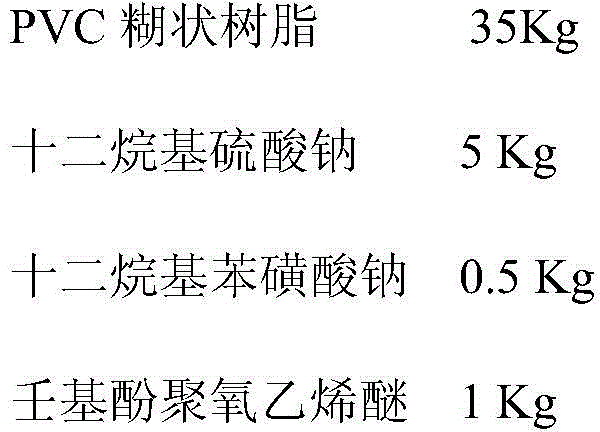

[0024] A high stability polyvinyl chloride recovery emulsion, comprising the following components in parts by weight:

[0025]

[0026] The preparation method of above-mentioned high stability polyvinyl chloride recovery emulsion is:

[0027] (1) Dilution of emulsifier: heat 95 kg of water to 80°C, add sodium lauryl sulfate and stir for 10 minutes to form an emulsion with a mass fraction of 5%;

[0028] (2) Resin emulsification: Take 65 kg of the prepared 5% emulsion, add PVC paste resin, and emulsify with a high-shear emulsifier at a temperature of 70°C for 30 minutes to obtain a polyvinyl chloride emulsion;

[0029] (3) Emulsion dispersion: Add nonylphenol polyoxyethylene ether and sodium dodecylbenzenesulfonate to the emulsified polyvinyl chloride emulsion and stir for 10 minutes to obtain a high-stable polyvinyl chloride recovery emulsion. The total solid mass fraction of the polyvinyl chloride emulsion is 35%, and there is no coagulation and delamination after standin...

Embodiment 2

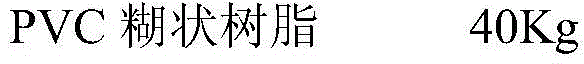

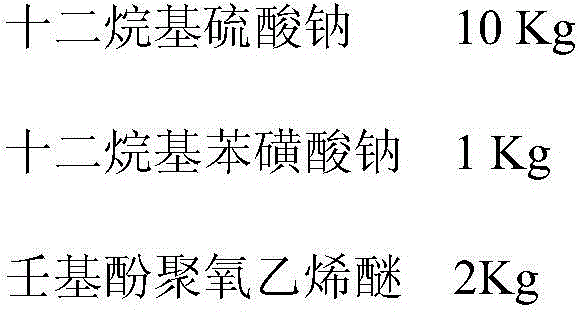

[0031] A high stability polyvinyl chloride recovery emulsion, comprising the following components in parts by weight:

[0032]

[0033]

[0034] The preparation method of above-mentioned high stability polyvinyl chloride recovery emulsion is:

[0035] (1) Dilution of emulsifier: heat 180 kg of water to 80°C, add sodium lauryl sulfate and stir for 10 minutes to form an emulsion with a mass fraction of 5%;

[0036] (2) Resin emulsification: take 80 kg of the prepared 5% emulsion, add PVC paste resin, emulsify at a temperature of 70°C with a high-shear emulsifier for 30 minutes, and obtain a polyvinyl chloride emulsion;

[0037] (3) Emulsion dispersion: Add nonylphenol polyoxyethylene ether and sodium dodecylbenzenesulfonate to the emulsified polyvinyl chloride emulsion and stir for 10 minutes to obtain a high-stable polyvinyl chloride recovery emulsion. The total solid mass fraction of the polyvinyl chloride emulsion is 35%, and there is no coagulation and delamination af...

Embodiment 3

[0039] A high stability polyvinyl chloride recovery emulsion, comprising the following components in parts by weight:

[0040]

[0041] The preparation method of above-mentioned high stability polyvinyl chloride recovery emulsion is:

[0042] (1) Dilution of emulsifier: heat 150 kg of water to 80°C, add sodium lauryl sulfate and stir for 10 minutes to form an emulsion with a mass fraction of 5%;

[0043] (2) Resin emulsification: Take 45 kg of the prepared 5% emulsion, add PVC paste resin, and emulsify with a high-shear emulsifier at a temperature of 70°C for 30 minutes to obtain a polyvinyl chloride emulsion;

[0044] (3) Emulsion dispersion: Add nonylphenol polyoxyethylene ether and sodium dodecylbenzenesulfonate to the emulsified polyvinyl chloride emulsion and stir for 10 minutes to obtain a high-stable polyvinyl chloride recovery emulsion. The total solid mass fraction of the polyvinyl chloride emulsion is 35%, and there is no coagulation and delamination after standi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com