Modified biochar and its preparation method and application

A biochar modification technology, applied in chemical instruments and methods, other chemical processes, water/sewage multi-stage treatment, etc., can solve problems such as poor decolorization effect, large consumption of flocculant, difficulty in filtration, etc., and achieve reduction Effect of treatment cost, increase in adsorption stability, and increase in adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

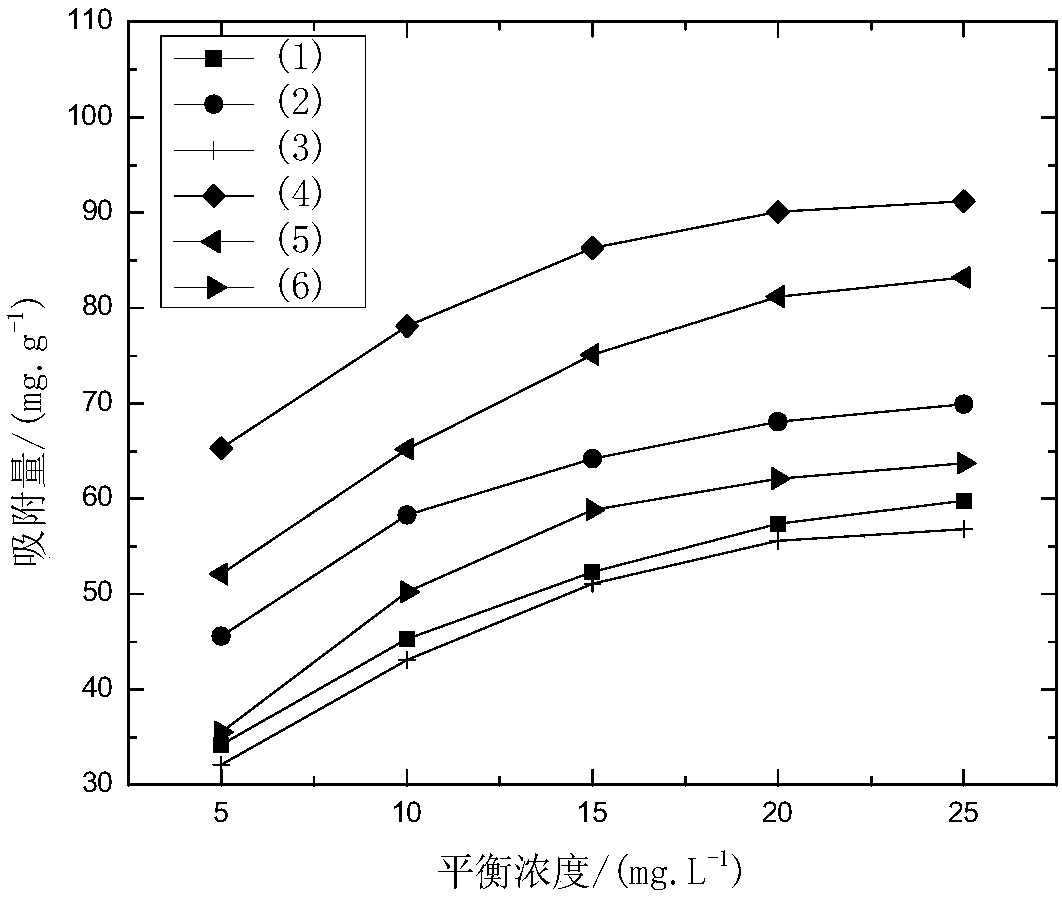

[0033] Determination of the adsorption capacity of acid-modified biomass charcoal

[0034] The preparation method of acid-modified biomass charcoal includes the following steps:

[0035] (1) Preparation of biomass charcoal

[0036] Rice husks, coconut husks, and wood chips collected from rural areas are crushed and mixed according to the mass ratio of rice husk, coconut husk and wood chips of 100~110:3~5:8~15. This example specifically selects six qualities. The ratios are 100:3:8, 100:5:8, 110:3:8, 110:5:8, 110:3:15 and 110:5:15, respectively, wash, air dry, and place in the vacuum / atmosphere tube Carbonized in an electric furnace at 400°C and nitrogen for 4 hours, and cooled to obtain 6 types of biomass carbon.

[0037] (2) Preparation of acid-modified biomass charcoal

[0038] Weigh 100g of the above 6 kinds of biomass charcoal in a reaction vessel, add 1L of hydrochloric acid solution with a concentration of 1mol / L, and soak in ultrasonic for 1h. Filter and separate, and collect ...

Embodiment 2

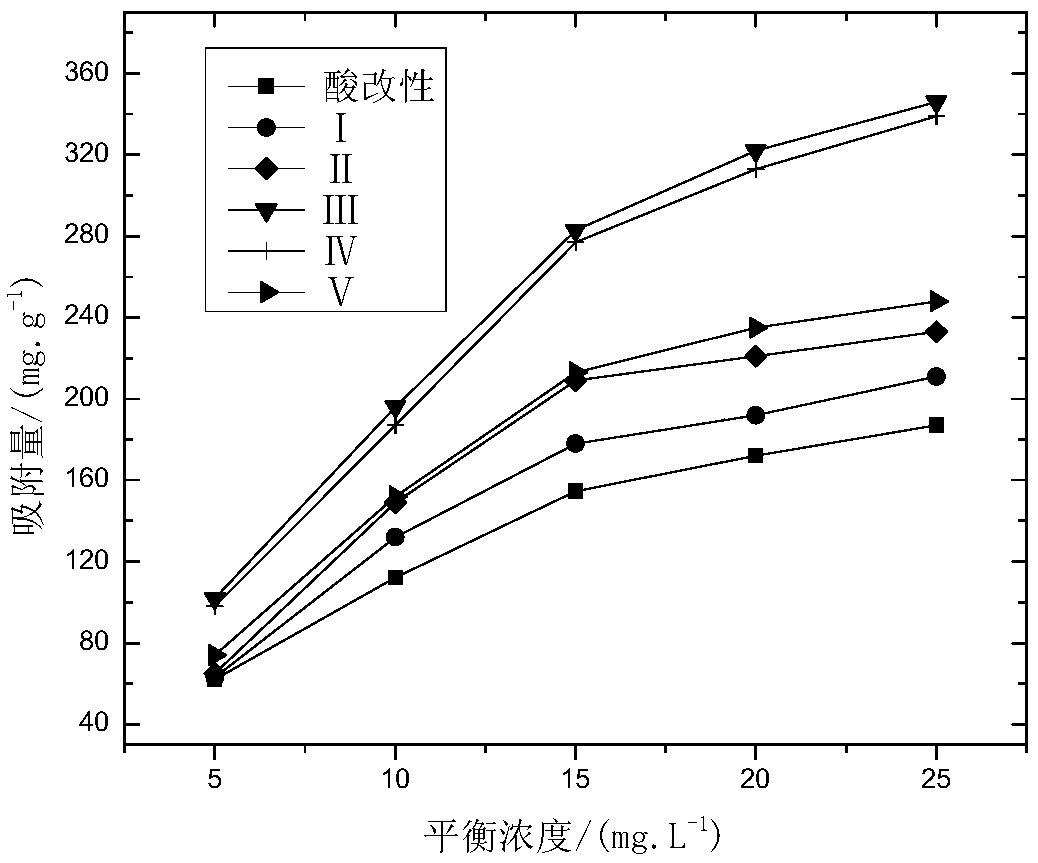

[0045] The modified biomass charcoal of the present invention is obtained by impregnating acid-modified biomass charcoal with a micellar system. The micellar system consists of an anionic biological surfactant, a cationic chemical surfactant and a humic acid solution.

[0046] In this embodiment, the anionic biosurfactant is rhamnolipid; the cationic chemical surfactant is the quaternary ammonium salt surfactant cetyltrimethylammonium bromide.

[0047] In this embodiment, the biomass charcoal is obtained by carbonization after mixing rice husk, coconut husk and wood chips.

[0048] A method for preparing modified biomass charcoal of this embodiment includes the following steps:

[0049] (1) Preparation of biomass charcoal

[0050] The rice husk, coconut husk and sawdust collected from the countryside are crushed and mixed according to the mass ratio of rice husk, coconut husk and sawdust at 110:5:8, washed and air-dried, and heated in a vacuum / atmosphere tube electric furnace at 400℃ I...

Embodiment 3

[0058] The modified biomass charcoal of the present invention is obtained by impregnating acid-modified biomass charcoal with a micellar system. The micellar system consists of an anionic biological surfactant, a cationic chemical surfactant and a humic acid solution.

[0059] In this embodiment, the anionic biosurfactant is rhamnolipid; the cationic chemical surfactant is the quaternary ammonium salt surfactant cetyltrimethylammonium bromide.

[0060] In this embodiment, the biomass charcoal is obtained by carbonization after mixing rice husk, coconut husk and wood chips.

[0061] A preparation method of the modified biomass charcoal of this embodiment is basically the same as the preparation method of Example 2, except that the volume ratio of the rhamnolipid solution, CTAB solution and humic acid solution in step (3) is 1 :6:20. The prepared modified biomass charcoal is numbered II.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com