Ecological soil stabilizer and preparation method thereof

An ecological soil and curing agent technology, applied in the field of building materials, can solve problems such as drying shrinkage cracks, failure to meet the requirements of complex engineering construction, environmental pollution, etc., and achieve the effects of reduced surface current, significant curing effect, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

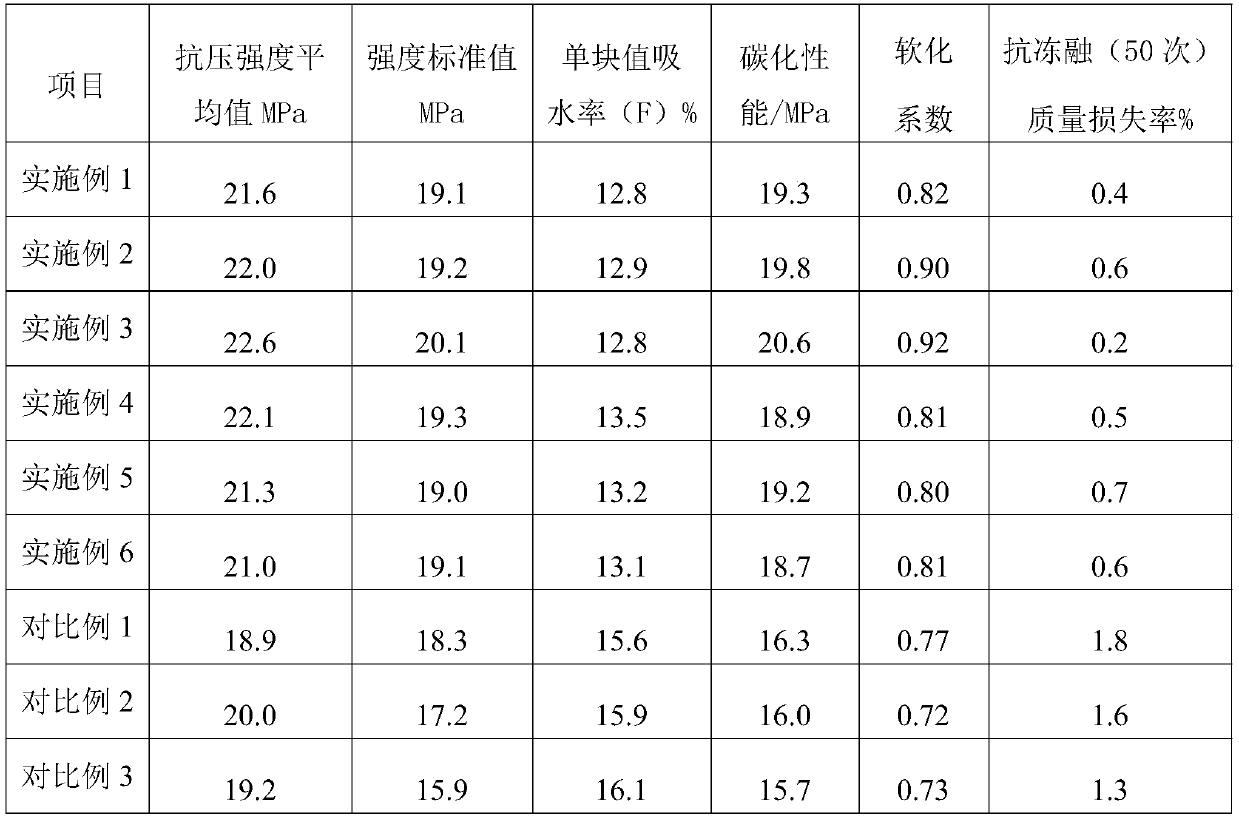

Examples

Embodiment 1

[0012] An ecological soil stabilizer, comprising the following raw materials in parts by weight: 0.01 part of dioctyl sulfosuccinate sodium salt, 0.7 part of lignin fiber, 30 parts of salt, 20 parts of hydroxypropyl methylcellulose, and 3 parts of sodium hydroxide , 1 part of polyvinyl alcohol, 0.075 parts of 2-ethylhexanol, 0.5 parts of isopropanol, and 500 parts of purified water.

Embodiment 2

[0014] An ecological soil stabilizer, comprising the following raw materials in parts by weight: 0.06 parts of dioctyl sulfosuccinate sodium salt, 3 parts of lignin fiber, 60 parts of salt, 50 parts of hydroxypropyl methylcellulose, and 18 parts of sodium hydroxide , 13 parts of polyvinyl alcohol, 0.3 parts of 2-ethylhexanol, 1.2 parts of isopropanol, and 900 parts of purified water.

Embodiment 3

[0016] An ecological soil stabilizer, comprising the following raw materials in parts by weight: 0.02 parts of dioctyl sulfosuccinate sodium salt, 1.3 parts of lignin fiber, 45 parts of salt, 30 parts of hydroxypropyl methylcellulose, and 11 parts of sodium hydroxide , 7 parts of polyvinyl alcohol, 0.19 parts of 2-ethylhexanol, 0.8 parts of isopropanol, 800 parts of purified water;

[0017] The raw materials in the above-mentioned Examples 1-3 were mixed and stirred at room temperature to obtain an ecological soil curing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com