Diaphragm coating, loudspeaker diaphragm and preparation method thereof, and electrostatic loudspeaker

A loudspeaker and coating technology, applied in electrostatic transducer loudspeakers, non-planar diaphragms/paper cones, sensors, etc., can solve the problems of affecting the service life of diaphragms, difficult to meet performance requirements, and poor low-frequency performance. High processing precision, improved electron migration speed, improved resolving power and sound pressure release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

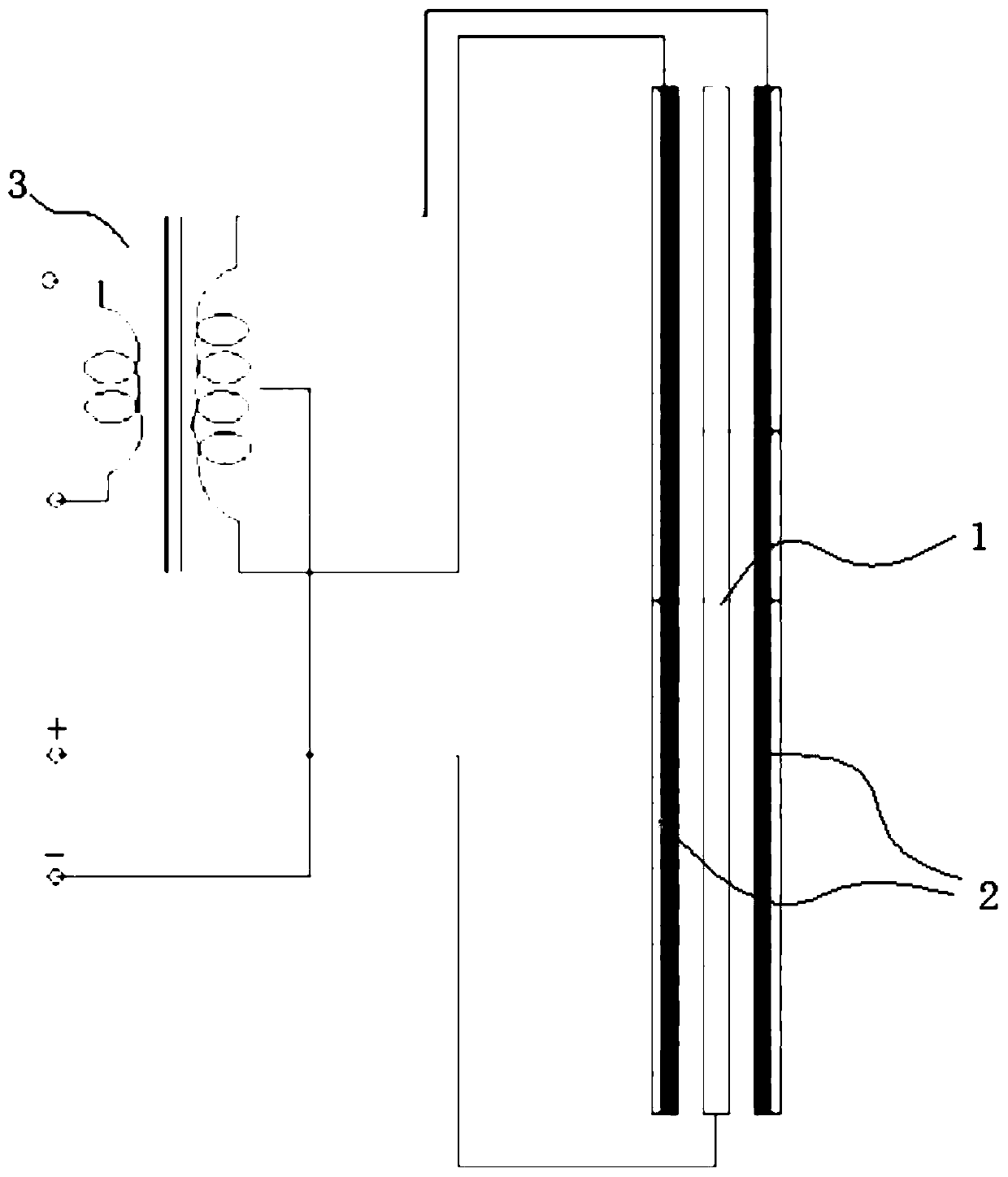

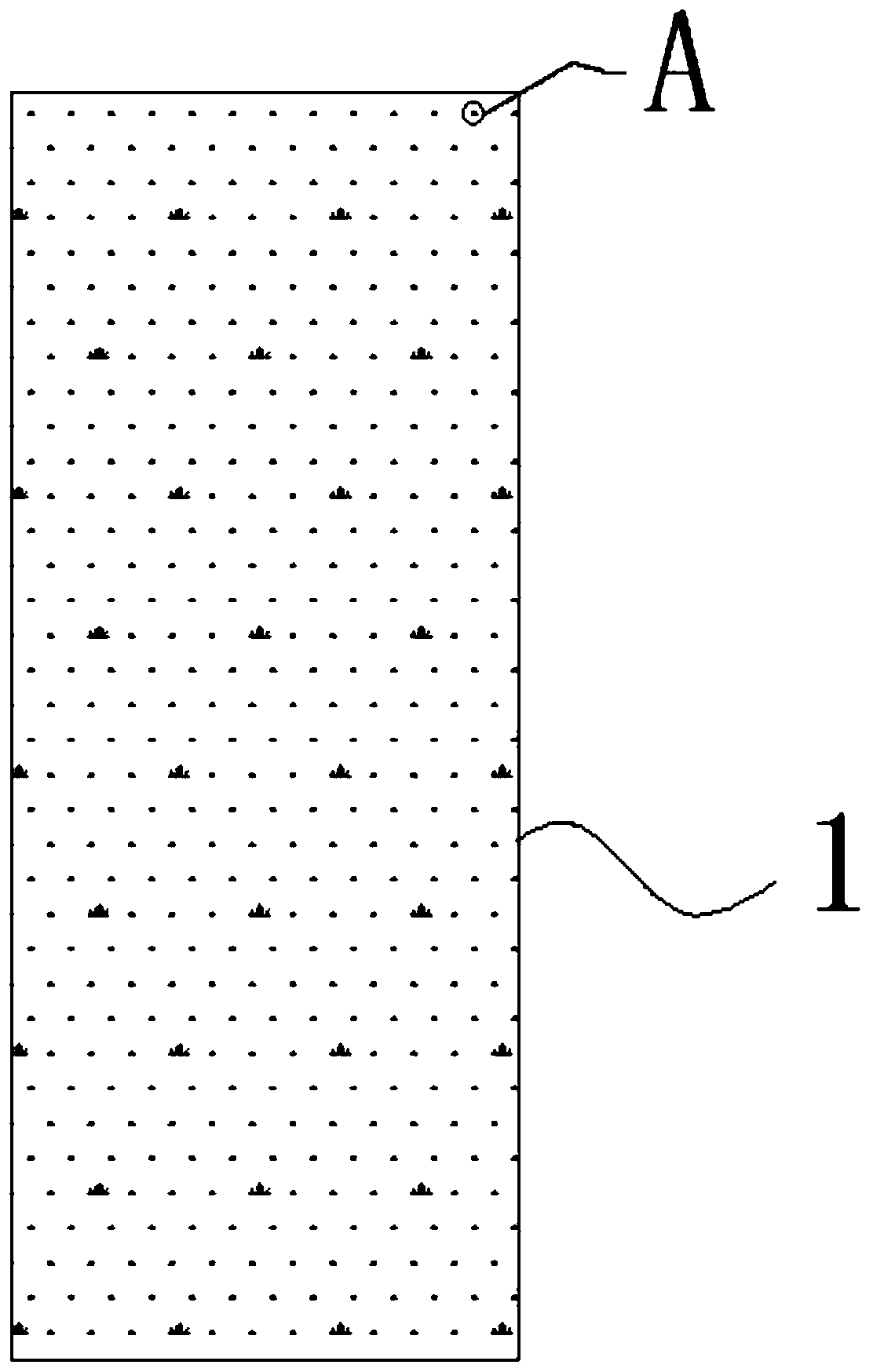

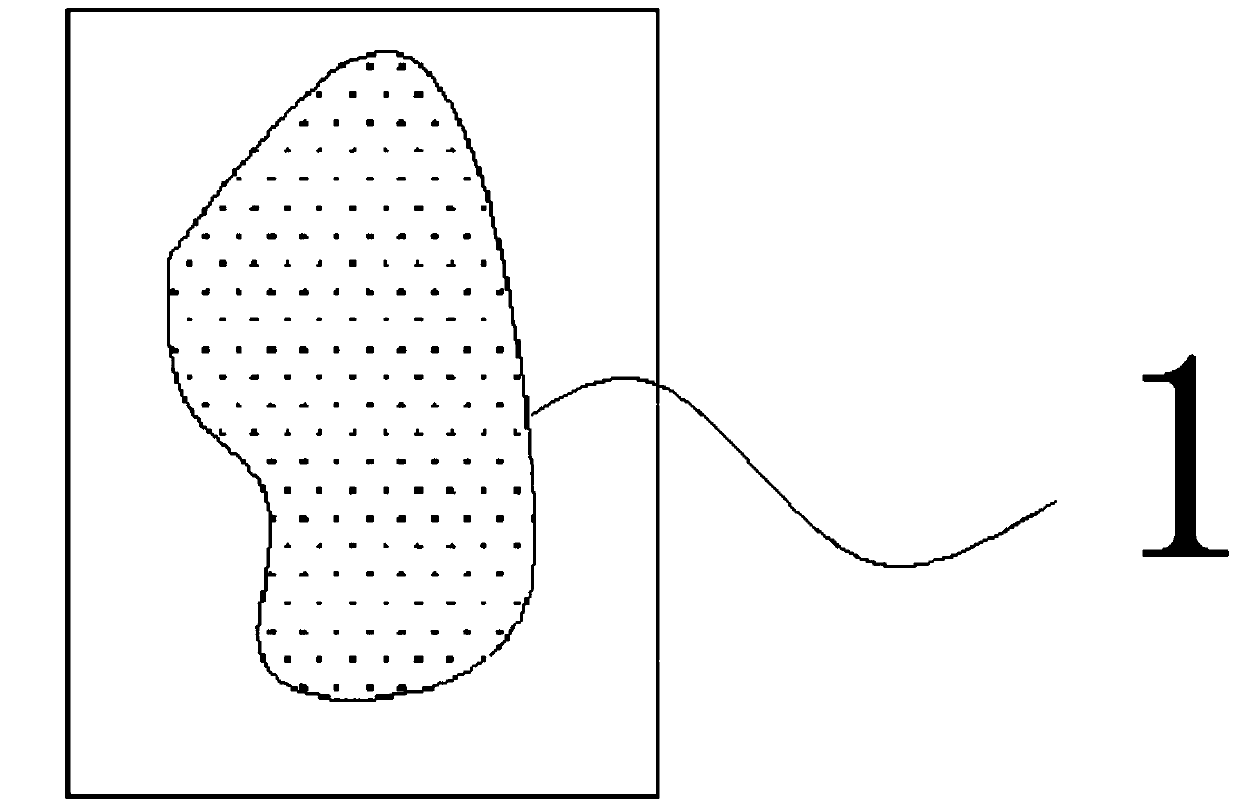

[0038] Such as Figure 2 to Figure 4 As shown, the diaphragm coating is made of the following components by weight:

[0039] 1 part of graphene slurry, 1 part of nano-carbon slurry, 1 part of metal nanoparticle dispersion, 10 parts of binder, 1 part of auxiliary agent, and 50 parts of solvent.

[0040] The graphene has 3 layers; the nano-carbon in the nano-carbon slurry is carbon black, and its particle size is 20nm. The metal nanoparticles in the metal nanoparticle dispersion liquid are copper nanoparticles with a particle diameter of 50 nm. The binder is alkyd resin. The auxiliary agent is 0.5 part of wetting and dispersing agent, 0.3 part of anti-settling agent and 0.2 part of defoaming agent; wetting and dispersing agent is amine wetting agent, including amides and polyethers; anti-settling agent is titanate, Polyamide or modified polyurea; defoamer is organosiloxane, amide or long chain alcohol; solvent is deionized water.

[0041] The loudspeaker diaphragm 1 comprise...

Embodiment 2

[0044] Such as Figure 2 to Figure 4 As shown, the diaphragm coating is made of the following components by weight:

[0045] 5 parts of graphene slurry, 5 parts of nano-carbon slurry, 5 parts of metal nanoparticle dispersion, 20 parts of binder, 2 parts of auxiliary agent, and 60 parts of solvent.

[0046] The graphene is 2 layers; the nano-carbon in the nano-carbon slurry is a nano-carbon sphere, and its particle size is 30nm. The metal nanoparticles in the metal nanoparticle dispersion liquid are nano silver with a particle diameter of 50nm. The binder is alkyd resin. The auxiliary agent is 1 part of dispersing wetting agent, 0.5 part of defoamer and 0.5 part of anti-settling agent; the wetting and dispersing agent is an amine wetting agent, including amides and polyethers; the anti-settling agent is titanate, Polyamide or modified polyurea; defoamer is organosiloxane, amide or long chain alcohol; solvent is ethanol.

[0047] The loudspeaker diaphragm 1 comprises two dia...

Embodiment 3

[0050] Such as Figure 2 to Figure 4 As shown, the diaphragm coating is made of the following components by weight:

[0051]15 parts of graphene slurry, 10 parts of nano-carbon slurry, 10 parts of metal nanoparticle dispersion, 25 parts of binder, 3 parts of auxiliary agent, and 60 parts of solvent.

[0052] The graphene is a single layer; the nano-carbon in the nano-carbon slurry is a carbon nanotube with a tube diameter of 20nm. The metal nanoparticles in the metal nanoparticle dispersion liquid are nano-nickel with a particle diameter of 100 nm. The binder is acrylate resin. The auxiliary agent is 1.5 parts of dispersing wetting agent, 0.5 part of defoamer and 1.0 part of anti-settling agent; the wetting and dispersing agent is an amine wetting agent, including amides and polyethers; the anti-settling agent is titanate, Polyamide or modified polyurea; defoamer is organosiloxane, amide or long chain alcohol; solvent is ethylene glycol.

[0053] The loudspeaker diaphragm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com