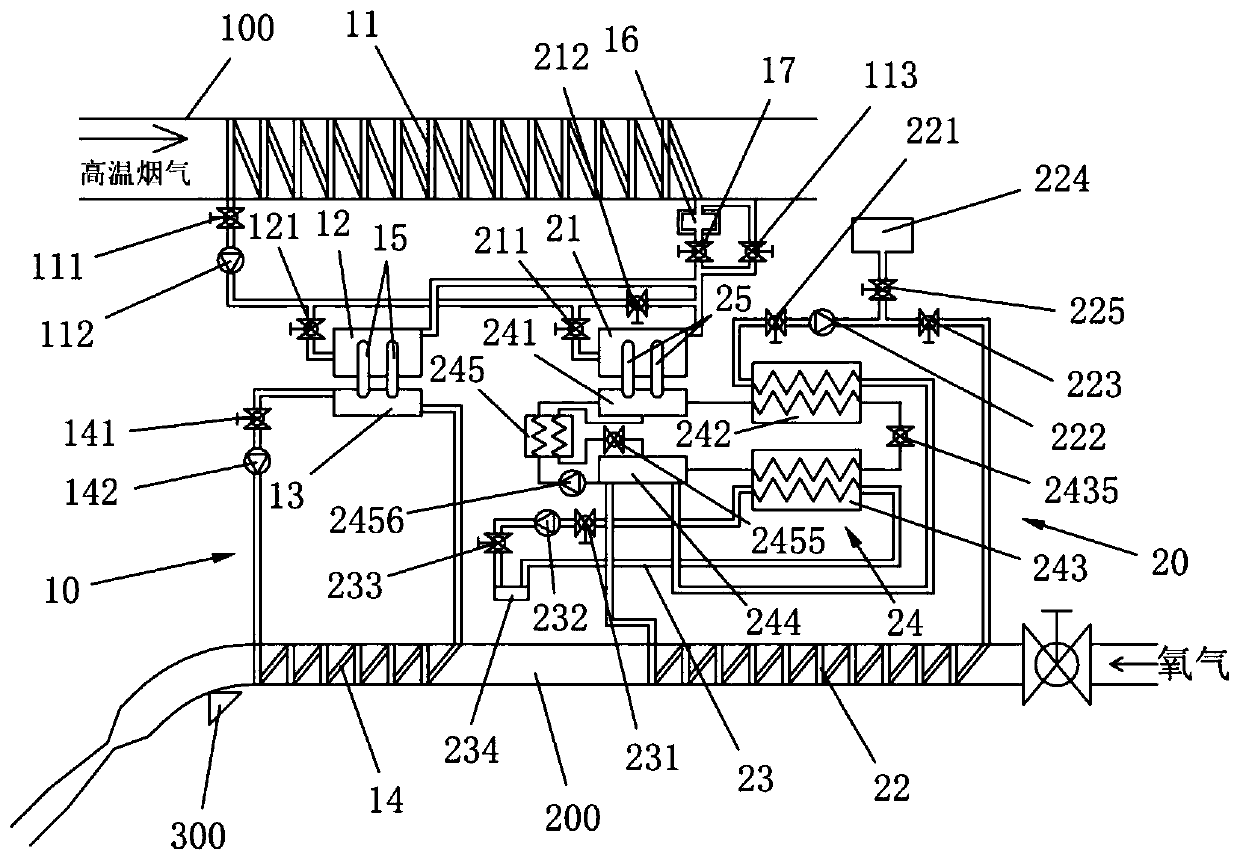

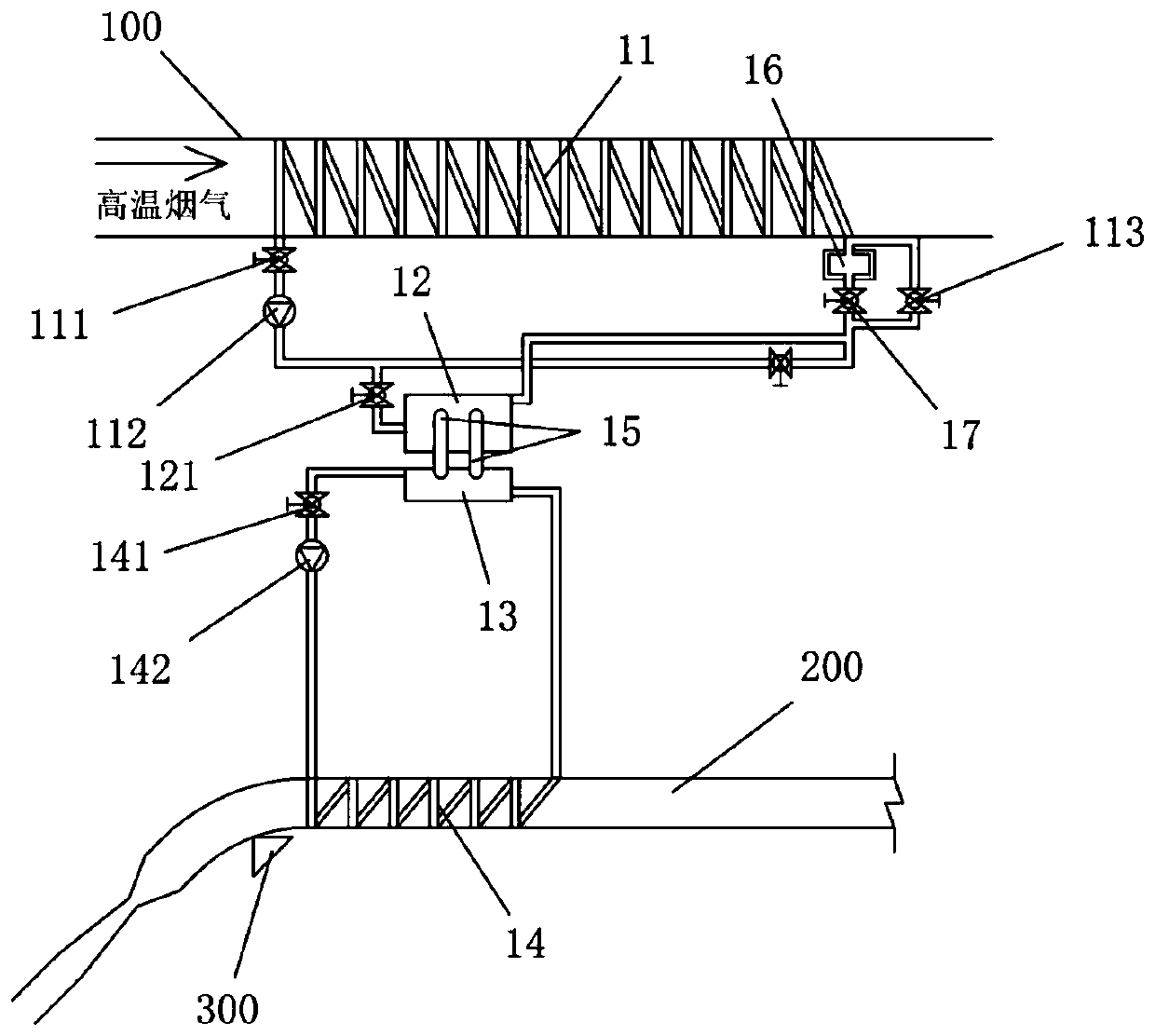

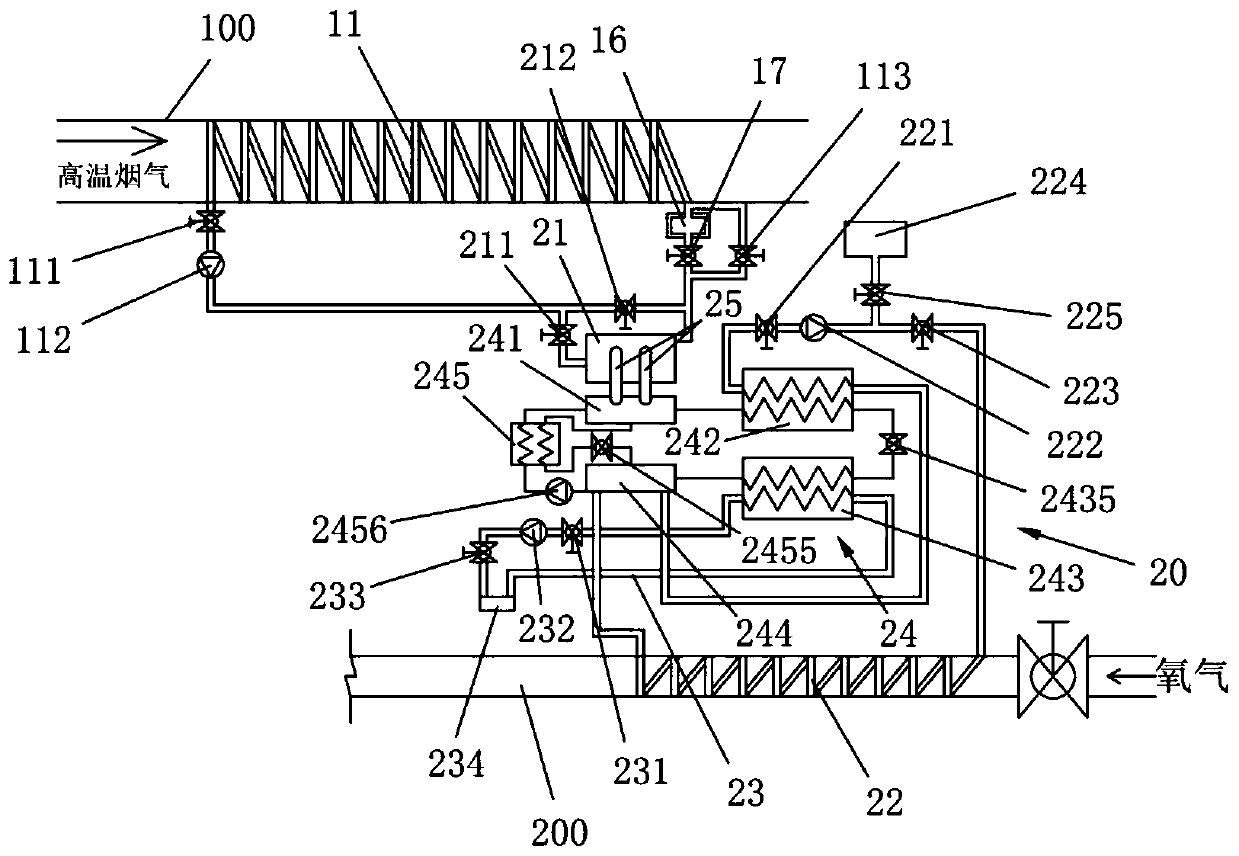

High-temperature flue gas heat recovery preheating type oxygen lance for electric arc furnace and application method thereof

A high-temperature flue gas and electric arc furnace technology, which is applied in climate change adaptation, furnace, waste heat treatment, etc., can solve the problem of large waste of heat in electric arc furnace flue gas, and achieve the goals of reducing energy resource consumption, saving resources, and accelerating decarbonization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0051] Unless otherwise defined, all technical terms used hereinafter have the same meanings as commonly understood by those skilled in the art. "First", "second" and similar words used in the patent application specification and claims of the present invention do not indicate any order, quantity or importance, but are only for the convenience of distinguishing corresponding components. Likewise, words like "a" or "one" do not indicate a limitation of quantity, but indicate that there is at least on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com