Catalyst for preparing formic acid through efficient electrocatalytic reduction of carbon dioxide and preparation method thereof

A carbon dioxide, electrocatalysis technology, applied in the field of electrocatalysis, to achieve the effect of high surface active site number, strong adsorption, improved activity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

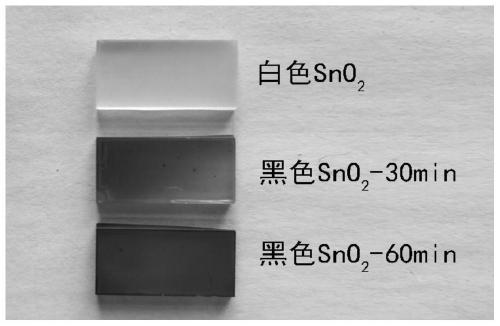

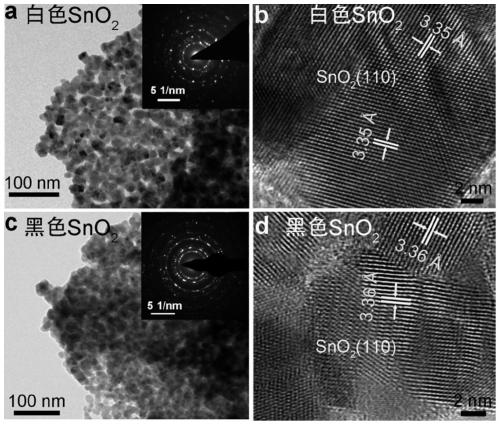

Image

Examples

Embodiment 1

[0027] Step 1: First, put 200mg of sulfur powder and 100mg of tin tetrachloride pentahydrate powder in separate aluminum oxide boats, respectively place them in the quartz tubes of the two central temperature zones of the dual-temperature zone atmosphere furnace, and put The FTO or CP substrate is placed at a distance of 9cm downstream of tin tetrachloride pentahydrate powder; secondly, the air in the quartz tube is exhausted with a flow rate of 1200sccm argon for 10min, and then the flow rate is respectively 45sccm and 15sccm of argon and 15sccm. Hydrogen was used as the carrier gas; finally, the temperature zones of sulfur powder and tin tetrachloride pentahydrate powder were raised to 250°C and 450°C respectively at a heating rate of 10°C / min; rate down to room temperature, the SnS 2 Nanosheet precursors.

[0028] Step 2: the prepared SnS 2 The nanosheet precursor was placed in an atmosphere furnace, and the temperature of the furnace was raised to 500 °C at a rate of 2 °...

Embodiment 2

[0032] Step 1: Put 200mg of sulfur powder and 100mg of tin tetrachloride pentahydrate powder in independent aluminum oxide boats, place them in the quartz tubes of the two central temperature zones of the dual-temperature zone atmosphere furnace respectively, and place FTO or The CP substrate is placed 9cm downstream of the tin tetrachloride pentahydrate powder; the air in the quartz tube is exhausted with argon gas at a flow rate of 1200 sccm for 10 minutes, and then argon gas and hydrogen gas with a flow rate of 45 sccm and 15 sccm respectively are introduced as the carrier flow gas; at a heating rate of 10 °C / min, the temperature zones of sulfur powder and tin tetrachloride pentahydrate powder were raised to 250 °C and 450 °C respectively; after holding for 5 min, the temperature was dropped to room temperature at a cooling rate of 10 °C / min. SnS 2 Nanosheet precursors.

[0033] Step 2: the prepared SnS 2 The nanosheet precursor was placed in an atmosphere furnace, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com