Fabric structure with water absorption and washing resistance functions

A fabric structure, washing-resistant technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problems of poor washing resistance, short service life, high production cost of fabrics, achieve a thick feel, reduce production costs, not easy to wrinkle and deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

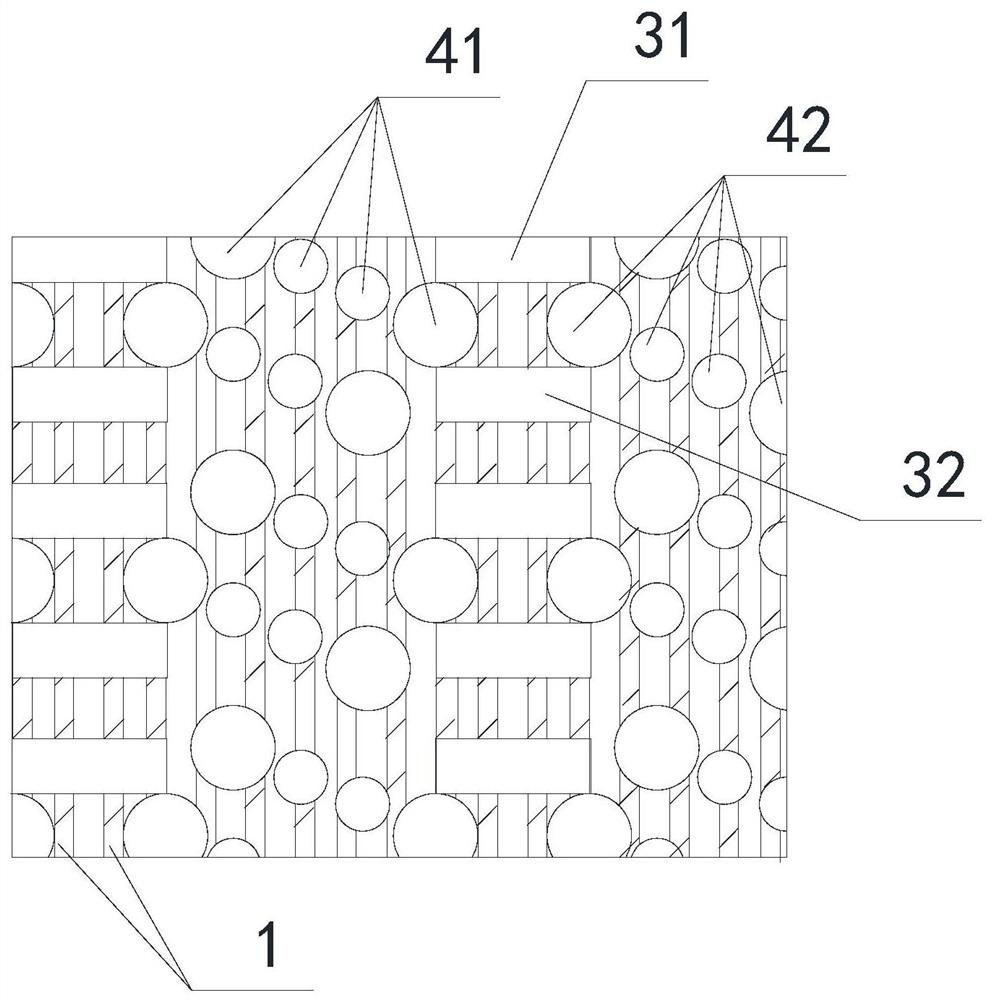

Image

Examples

specific Embodiment 1

[0021] In this embodiment, the warp thread adopts 75D / 72F polyester low-elastic network yarn, and the weft thread adopts 600D / 576F polyester low-elastic network yarn. %g / ㎡, the door width is 62.75 inches.

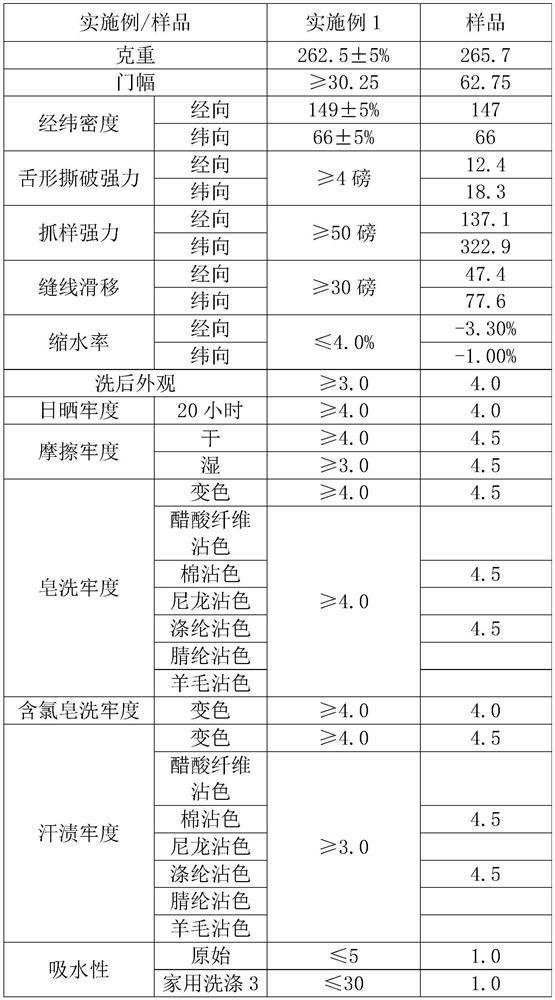

[0022] The parameters of above-mentioned embodiment and sample thereof are as follows:

[0023]

[0024]

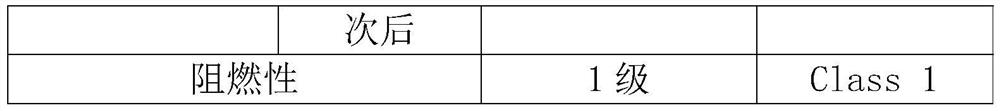

[0025] According to the above table, it can be seen that the finished fabric woven by the fabric structure provided by the present invention has good water absorption. Under the test of water absorption, the water absorption time of the original finished fabric and the finished fabric after household washing for 3 times is 1.0 seconds. , shows that the finished fabric woven by the fabric structure provided by the present invention has good water absorption, and its good water absorption characteristics will not change due to washing; under the shrinkage test, the warp shrinkage and weft shrinkage of the finished fabric The rate is less than 4%, and the finished ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com