A pipe transportation device

A technology for transporting equipment and pipes, applied in the field of transportation, can solve the problems of not keeping the axis of the tubular product perpendicular to the transportation direction, and not being able to transport tubular products of different sizes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

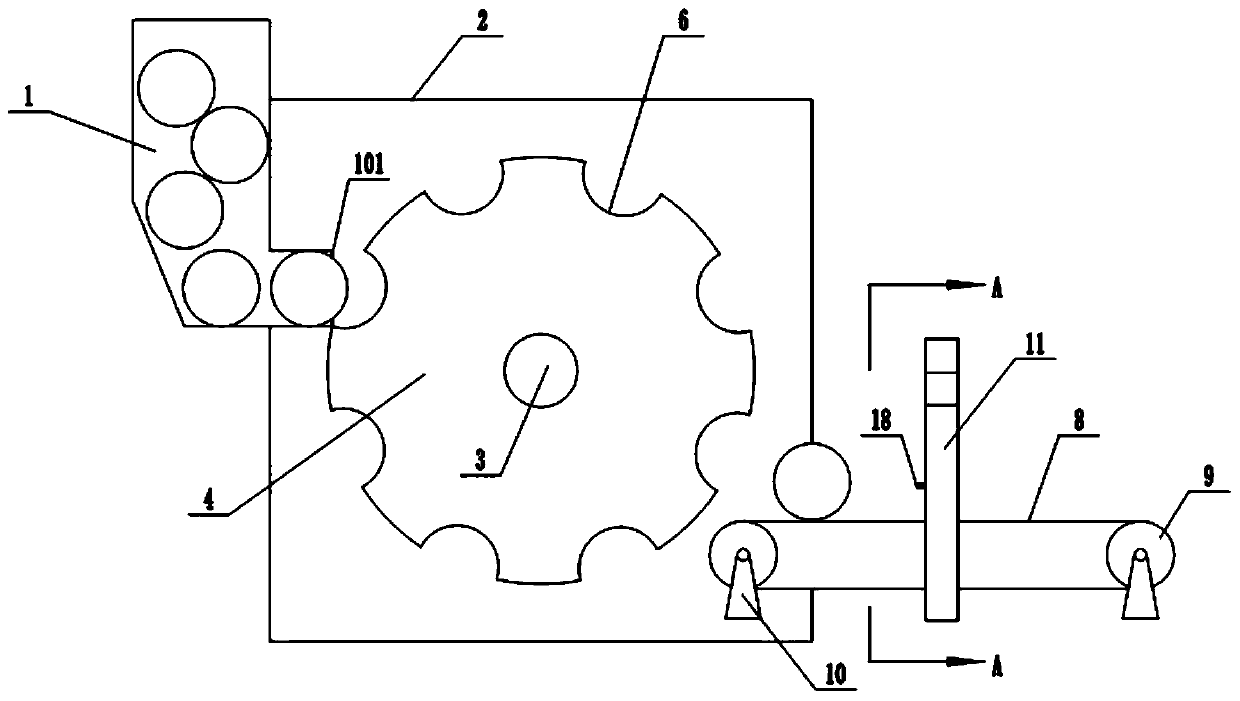

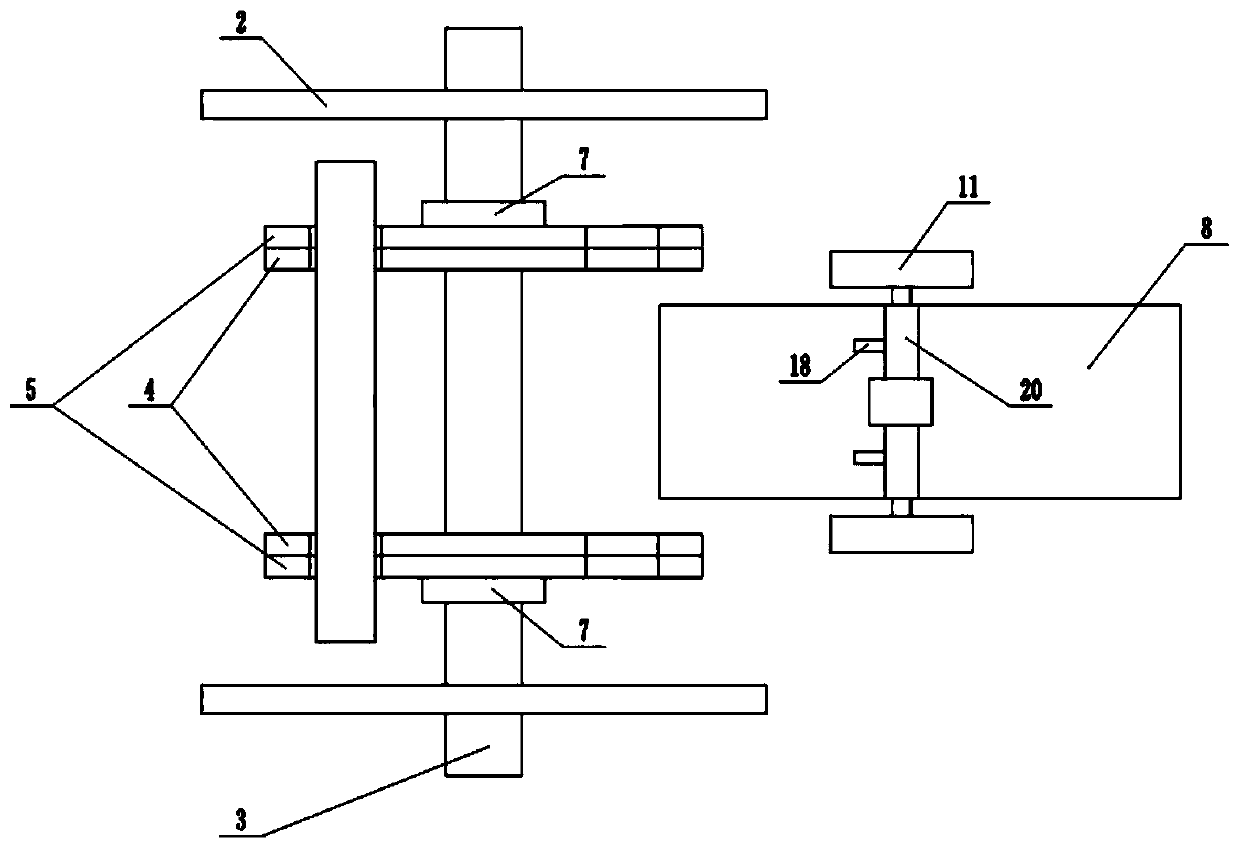

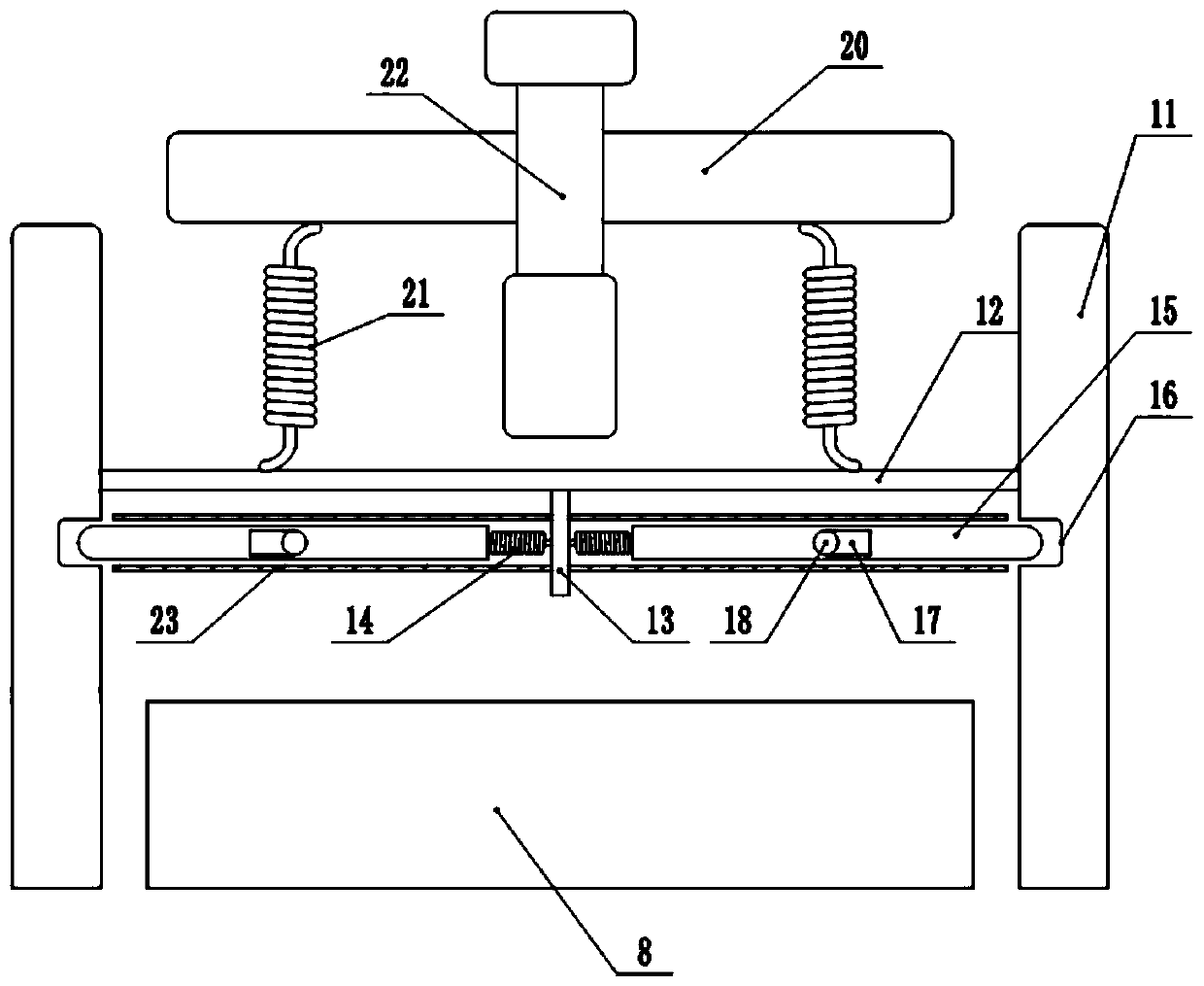

[0018] The reference signs in the drawings of the description include: unloading device 1, discharge port 101, housing 2, rotating shaft 3, feeding tray 4, adjusting disc 5, groove 6, fixing nut 7, conveyor belt 8, runner 9. Rack 10, support plate 11, lower baffle 12, partition 13, elastic member 14, control rod 15, card slot 16, wedge-shaped chute 17, pressing piece 18, wedge-shaped end 19, upper baffle 20, Elastic stretching member 21, air pressure telescopic device 22, limit tube 23.

[0019] The embodiment is basically as attached figure 1 ~ attached Figure 4 Shown: including a blanking device 1, the blanking device 1 is provided with a discharge port 101, the end of the discharge port 101 is connected with a feeding device, one side of the feeding device is provided with a conveying device, and the conveying device The upper end is provided with an adjustment dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com