Furnace tube inner support welding equipment for solar cell silicon wafer diffusion

A technology for solar cells and welding equipment, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems affecting the accuracy of the furnace tube, the thermometer cannot be completely inserted into the bracket horizontally, and the service life of experimental measuring equipment is affected. , to achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

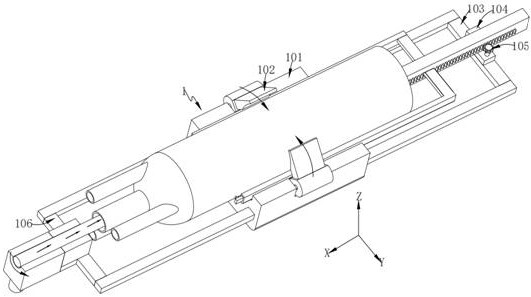

[0082] like Figure 1-2 As shown, a furnace tube inner bracket welding equipment for solar cell silicon wafer diffusion includes:

[0083] positioning unit 1;

[0084] a feeding unit 2, the feeding unit 2 is provided in the furnace tube positioned by the positioning unit 1; and

[0085] Welding unit 3, the welding unit 3 for welding the bracket to the inner wall of the furnace tube is provided on the side of the feeding unit 2;

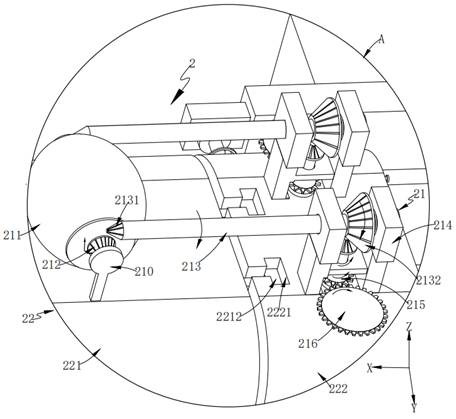

[0086] The feeding unit 2 includes:

[0087] a lift assembly 22 for adjusting the contact state of the clutch roller 211 with the furnace tube to drive the feeding unit 2 to move in a linear direction along the furnace tube; and

[0088] The driving component 21 is arranged on the upper part of the lifting component 22 for automatically driving the welding unit 3 to perform fixed-length welding work.

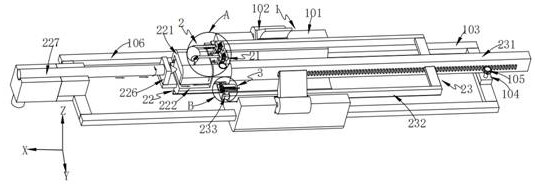

[0089] as an improvement, such as figure 2 As shown, the positioning unit 1 includes:

[0090] stage 101;

[0091] The splint 102, the splint 1...

Embodiment 2

[0149] like Figure 7-10 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the second embodiment and the first embodiment is:

[0150] As an improvement, the feeding unit 2 further includes a push-pull assembly 23;

[0151] The push-pull assembly 23 includes a transmission rod 231;

[0152] an auxiliary frame 232, the auxiliary frame 232 is connected to the upper position of the side of the transmission rod 231;

[0153] The heater 233 is connected to the end of the auxiliary frame 232 .

[0154] Further, the heater 233 installed at the end of the auxiliary frame 232 is aligned with the welding unit 3;

[0155] A guide groove is provided on the outside of the auxiliary frame 232 and inside the positioning unit 1 .

[0156] It should be noted that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com