Novel thermal conductive insulating plastic

A heat-conducting insulation and plastic technology, applied in the field of new heat-conducting and insulating plastics, can solve the problems of difficult processing of composite materials, low thermal conductivity, poor impact strength, etc., and achieve obvious cost advantages and performance advantages, simple operation steps, and heat conduction The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

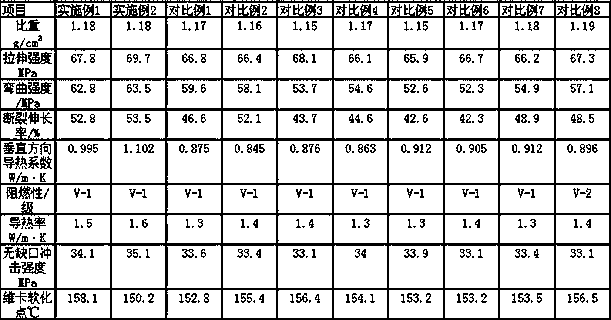

Examples

Embodiment 1

[0022] A new type of thermally conductive and insulating plastic, made of the following raw materials in parts by weight: 229 parts of styrene monomer, 2.9 parts of dibenzoyl peroxide, 1200 parts of deionized water, 2 parts of polyvinyl alcohol, polystyrene sulfonic acid 3.4 parts of sodium, 2.7 parts of aniline, 4.7 parts of 3,4-ethylenedioxythiophene, 0.1 part of catalyst, 2.1 parts of actinolite powder, 0.4 parts of regulator, 1 part of stabilizer, 3.5 parts of polyphosphazene, fullerene loading agent 6.5 parts, 160 parts of polyphenylene ether resin, 12.3 parts of acicular α-alumina, 15.3 parts of nano-silica, 0.6 parts of antioxidant, 0.6 parts of lubricant, and 1.9 parts of flame retardant.

[0023] Further, the polyphenylene ether resin is polystyrene-modified polyphenylene ether with a styrene content of 31%, 250° C., 5 kg, and a melt flow rate of 33 g / 10 min.

[0024] Further, the catalyst is a mixture of sodium persulfate, potassium persulfate and ammonium persulfate...

Embodiment 2

[0034] A new type of thermally conductive and insulating plastic, made of the following raw materials in parts by weight: 176 parts of styrene monomer, 2.3 parts of dibenzoyl peroxide, 1000 parts of deionized water, 1 part of polyvinyl alcohol, polystyrene sulfonic acid 2.5 parts of sodium, 1.3 parts of aniline, 1.9 parts of 3,4-ethylenedioxythiophene, 0.08 parts of catalyst, 2.1 parts of actinolite powder, 0.4 parts of regulator, 1 part of stabilizer, 3.5 parts of polyphosphazene, fullerene loading agent 6.5 parts, 160 parts of polyphenylene ether resin, 8.1 parts of acicular α-alumina, 11.5 parts of nano-silica, 0.6 parts of antioxidant, 0.4 parts of lubricant, and 1.2 parts of flame retardant.

[0035] Further, the polyphenylene ether resin is polystyrene-modified polyphenylene ether with a styrene content of 29%, 250° C., 5 kg, and a melt flow rate of 33 g / 10 min.

[0036] Further, the catalyst is a mixture of sodium persulfate, potassium persulfate and ammonium persulfate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com