Plant cellulose absorption sponge, and preparation method and application of plant cellulose absorption sponge

A plant cellulose and sponge technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problems of difficult to achieve solid-liquid separation, increase the cost of treatment process, loss of adsorption materials, etc., and achieve reduction Economic cost and human effort, easy solid-liquid separation, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

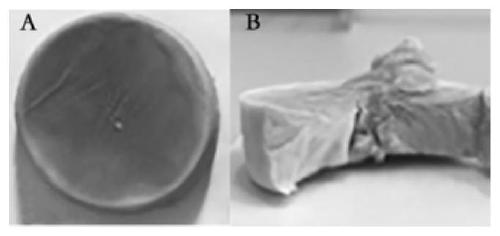

Image

Examples

Embodiment 1

[0030] A kind of embodiment of the preparation method of plant cellulose absorption sponge of the present invention, it comprises the following steps:

[0031] (1) cleaning the collected turfgrass with water to remove impurities, then drying and grinding to obtain grass powder;

[0032] (2) Weigh 1 g of the grass powder obtained by step (1), add 50 mL of sodium hydroxide solution with a mass fraction of 14% and 3 mL of carbon disulfide, and continuously stir and react at room temperature for 6 hours. After the reaction, centrifuge at a speed of 8000 rpm Collect the solid product after the reaction, and repeatedly wash with deionized water until the solid product is neutral;

[0033] (3) Mix the neutral solid product obtained in step (2) and pour it into a container of a certain shape, such as a 50mL, 100mL beaker of different specifications, and then store it at -20°C, -50°C, -80°C Or rapidly freeze at -198° C. until completely agglomerated, and then freeze and vacuum-dry to ...

Embodiment 2

[0035] A kind of embodiment of the preparation method of plant cellulose absorption sponge of the present invention, it comprises the following steps:

[0036] (1) cleaning the collected turfgrass with water to remove impurities, then drying and grinding to obtain grass powder;

[0037](2) Weigh 0.5 g of grass powder obtained through step (1), add 40 mL of sodium hydroxide solution and 0.5 mL of carbon disulfide with a mass fraction of 5%, and continuously stir and react at room temperature for 6 hours. The solid product after the reaction was collected by rotating speed centrifugation, and was repeatedly washed with deionized water until the solid product was neutral;

[0038] (3) Mix the neutral solid product obtained in step (2) and pour it into a container of a certain shape, such as a 50mL, 100mL beaker of different specifications, and then store it at -20°C, -50°C, -80°C Or rapidly freeze at -198° C. until completely agglomerated, and then freeze and vacuum-dry to obtai...

Embodiment 3

[0040] A kind of embodiment of the preparation method of plant cellulose absorption sponge of the present invention, it comprises the following steps:

[0041] (1) cleaning the collected turfgrass with water to remove impurities, then drying and grinding to obtain grass powder;

[0042] (2) Weigh 0.5g of grass powder obtained by step (1), add 70mL of sodium hydroxide solution and 2mL of carbon disulfide with a mass fraction of 15%, and continuously stir and react at room temperature for 12h. The solid product after the reaction was collected by centrifugation, and was repeatedly washed with deionized water until the solid product was neutral;

[0043] (3) Mix the neutral solid product obtained in step (2) and pour it into a container of a certain shape, such as a 50mL, 100mL beaker of different specifications, and then store it at -20°C, -50°C, -80°C Or rapidly freeze at -198° C. until completely agglomerated, and then freeze and vacuum-dry to obtain a turfgrass adsorption sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com