A kind of preparation method of vanadium dioxide nanopowder

A vanadium dioxide nanometer and powder technology, applied in vanadium oxide, nanotechnology and other directions, can solve the problems of high energy consumption of hydrothermal reaction, unfavorable large-scale production, difficulty in continuous production, etc., and achieves low production cost and easy large-scale production. The effect of producing and avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of a kind of vanadium dioxide nano-powder provided by this embodiment, it comprises the following steps:

[0036] Step 1, adding a certain amount of tetravalent vanadium salt to deionized water, and stirring until completely dissolved to obtain solution a;

[0037] Step 2, adding a certain amount of precipitant to the solution a, adjusting the pH to 8-12, and stirring for a period of time to obtain a suspension b;

[0038] Step 3, separating the suspension b to obtain the precipitate c, dispersing the precipitate c in deionized water, adding a certain amount of hydrogen peroxide, adjusting the pH to 3-6, and aging at room temperature for 1-6 hours to obtain the suspension d;

[0039] Step 4, separating the suspension d to obtain the precipitate e, drying the precipitate e for a period of time, calcining at 450-700° C. for 1-5 hours under the protection of an inert gas, and cooling to room temperature to obtain the vanadium dioxide nano-powder.

...

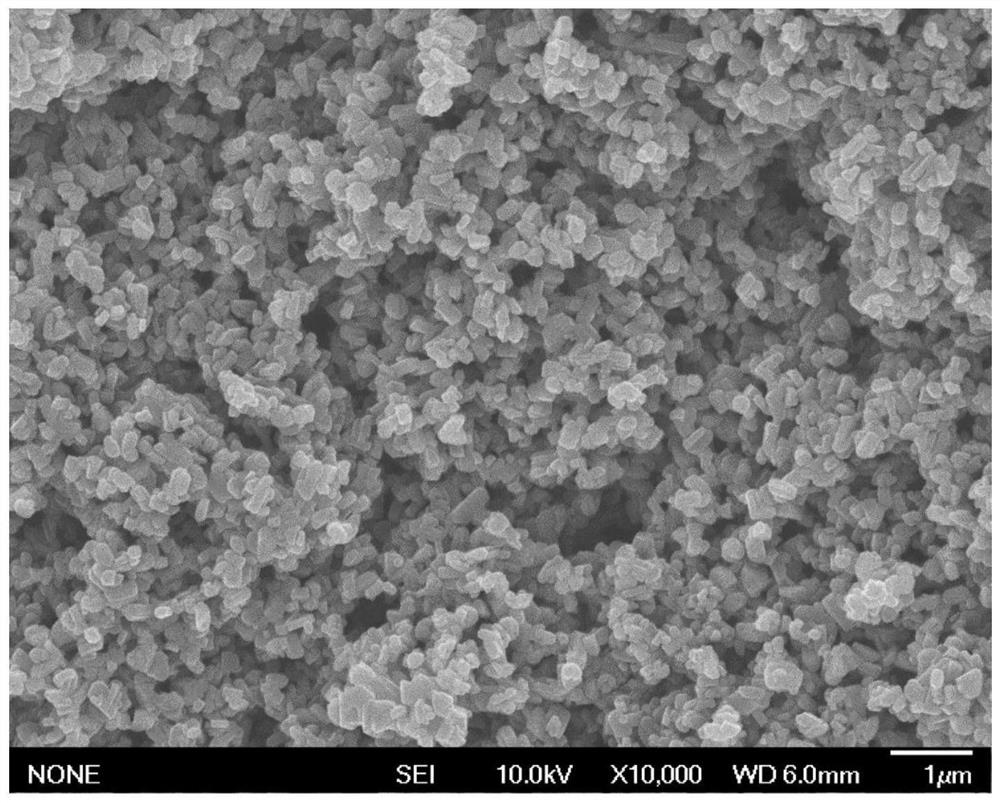

Embodiment 1

[0047] Embodiment 1: a kind of preparation method of vanadium dioxide nano powder comprises the following steps:

[0048] Step 1, dissolve 3 g of vanadyl oxalate in deionized water, stir with an electromagnetic stirrer until it is completely dissolved, and prepare 100 mL of solution a with a concentration of 0.12 mol / L;

[0049] Step 2, slowly add ammonia water with a mass percentage concentration of 20% to solution a, until the pH of solution a=9, and continue to stir for 0.5 hours to obtain suspension b;

[0050] Step 3, the suspension b is filtered and separated to obtain a precipitate c, the precipitate c is dispersed in 100 mL of deionized water, and the hydrogen peroxide whose mass percentage concentration is 10% is slowly added dropwise while stirring, wherein, the molar ratio of vanadyl oxalate: ammonia water: hydrogen peroxide The ratio is 1:2:0.2, the pH is adjusted to 4, and it is aged for 2 hours at room temperature to obtain suspension d;

[0051] In step 4, the ...

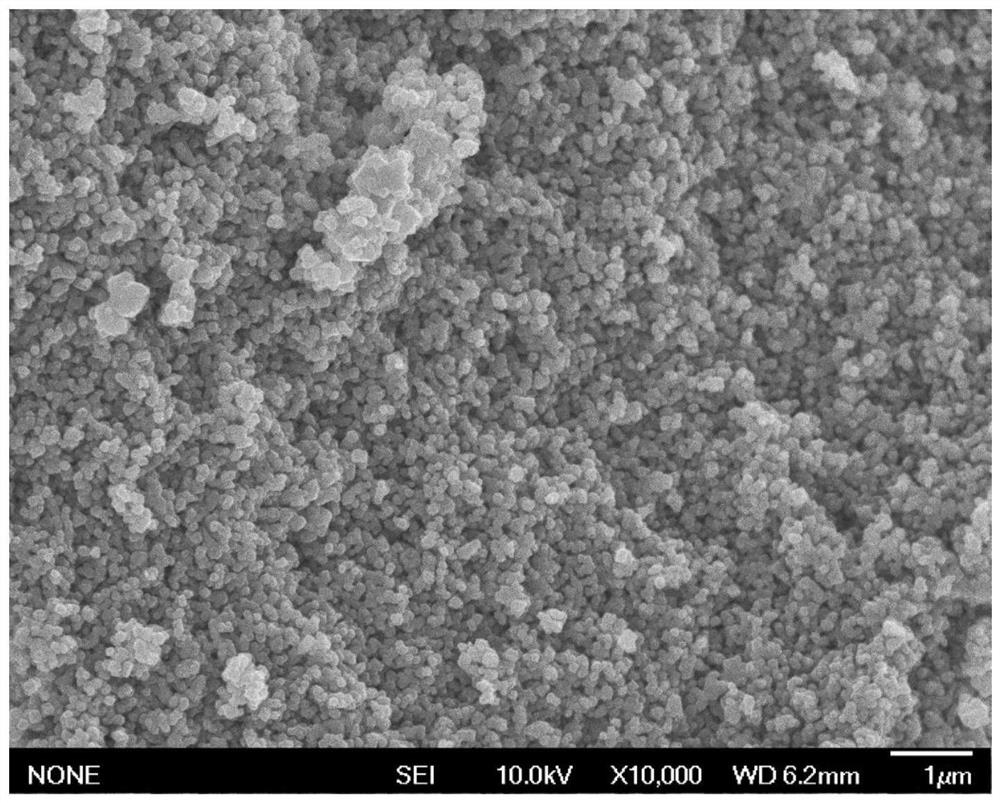

Embodiment 2

[0053] Embodiment 2: a kind of preparation method of vanadium dioxide nano powder comprises the following steps:

[0054] Step 1, dissolve 1.6 g of vanadyl sulfate in deionized water, stir with an electromagnetic stirrer until it is completely dissolved, and prepare 100 mL of solution a with a concentration of 0.10 mol / L;

[0055] Step 2, slowly add 10% ammonium bicarbonate solution dropwise to solution a until the pH of solution a=10, and continue stirring for 1 hour to obtain suspension b;

[0056] Step 3, the suspension b was filtered and separated to obtain the precipitate c, the precipitate c was dispersed in 100 mL of deionized water, and the hydrogen peroxide with a mass percentage concentration of 8% was slowly added dropwise while stirring, wherein, vanadyl sulfate: ammonium bicarbonate: hydrogen peroxide The molar ratio is 1.3:2.8:0.4, the pH is adjusted to 5, and it is aged at room temperature for 4 hours to obtain suspension d;

[0057] In step 4, the suspension d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com