Diamond rope saw bead added with cubic boron nitride and preparation process of diamond rope saw

A cubic boron nitride and diamond wire saw technology, which is applied in the manufacture of tools, metal processing, stone processing equipment, etc., can solve the problems affecting sharpness, cutting effect and service life, loss of diamond cutting ability, and fast wear of wire saws, etc. , to achieve the effects of reducing the difficulty of coating, enhancing wear resistance and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment relates to a diamond wire saw bead added with cubic boron nitride and a preparation process of the diamond wire saw.

[0037] A diamond wire saw bead, comprising the following raw material components in parts by mass:

[0038] 91-95 parts of metal powder, 0.5-2.5 parts of diamond, 1.5-5.3 parts of cubic boron nitride; the particle size of the metal powder is 200-400 mesh, the particle size of the diamond is 25-60 mesh, and the cubic boron nitride The particle size of boron is 25-60 mesh;

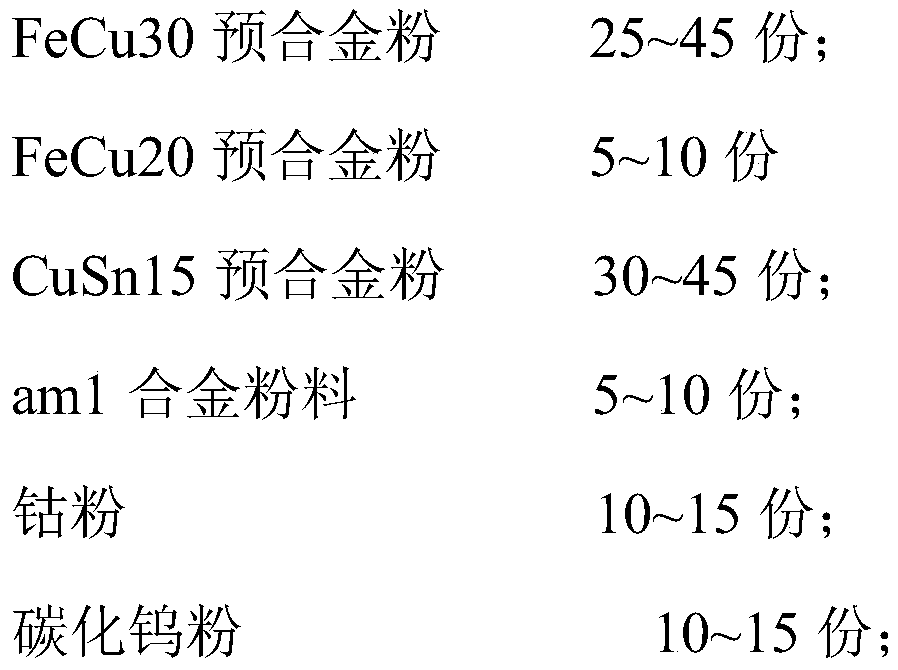

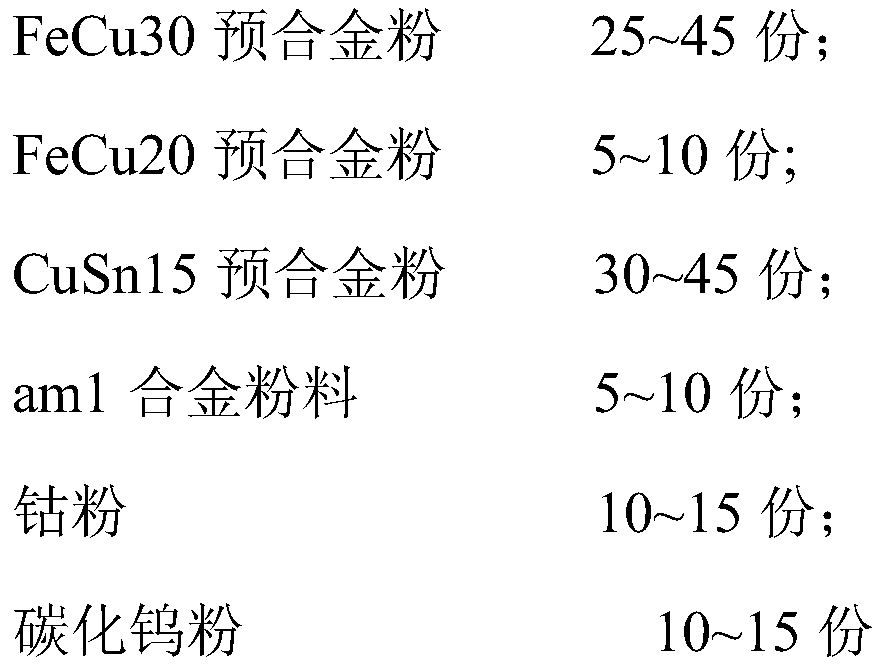

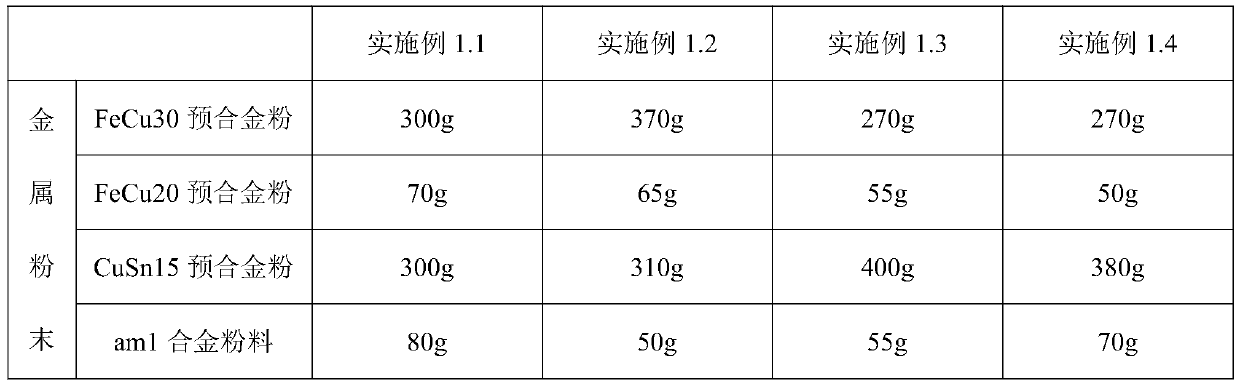

[0039] Among them, every hundred parts of metal powder includes the following mass powder raw material components: 25-45 parts of FeCu30 pre-alloyed powder, 5-10 parts of FeCu20 pre-alloyed powder, 30-45 parts of CuSn15 pre-alloyed powder, 5-10 parts of am1 alloyed powder , 10-15 parts of cobalt powder, 10-15 parts of tungsten carbide powder; the particle size of the FeCu30 pre-alloy powder, FeCu20 pre-alloy powder, CuSn15 pre-alloy powder, am1 alloy powder, cobalt po...

Embodiment 2

[0056] This embodiment relates to the use effect of the diamond wire saw.

[0057] The performance of the diamond wire saw prepared in Examples 1.1 to 1.4 is tested, and its use effect is tested as follows:

[0058] The diamond wire saw obtained in Example 1.1 has a cutting power of 22kw, and the sample specification is: φ11.5mm beads, 50m, 40 beads per meter. Test the diamond wire saw obtained by using a test block (c40 cement, containing 8 18mm steel bars per square meter), and its cutting speed can reach 25min / m 2 , service life up to 230m 2 .

[0059] The diamond wire saw obtained in Example 1.2 has a cutting power of 22kw, and the sample specification is: φ11.5mm beads, 50m, 40 beads per meter. Test the diamond wire saw obtained by using a test block (c40 cement, containing 8 18mm steel bars per square meter), and its cutting speed can reach 22min / m 2 , service life up to 235m 2 .

[0060] The diamond wire saw obtained in Example 1.3 has a cutter power of 22kw, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com