Method for preparing nickel-cobalt sulfide/graphene composite zinc-air battery bifunctional catalyst

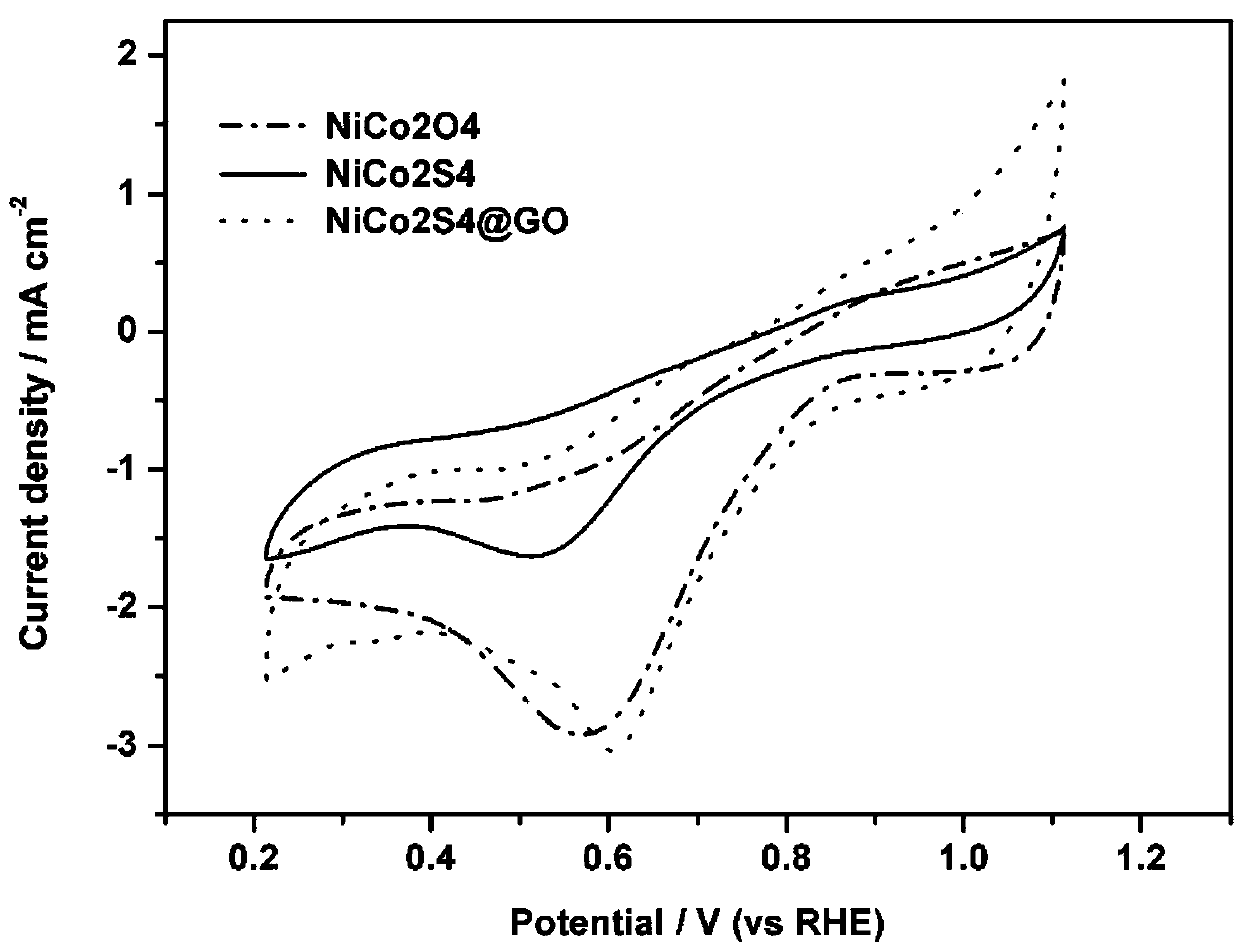

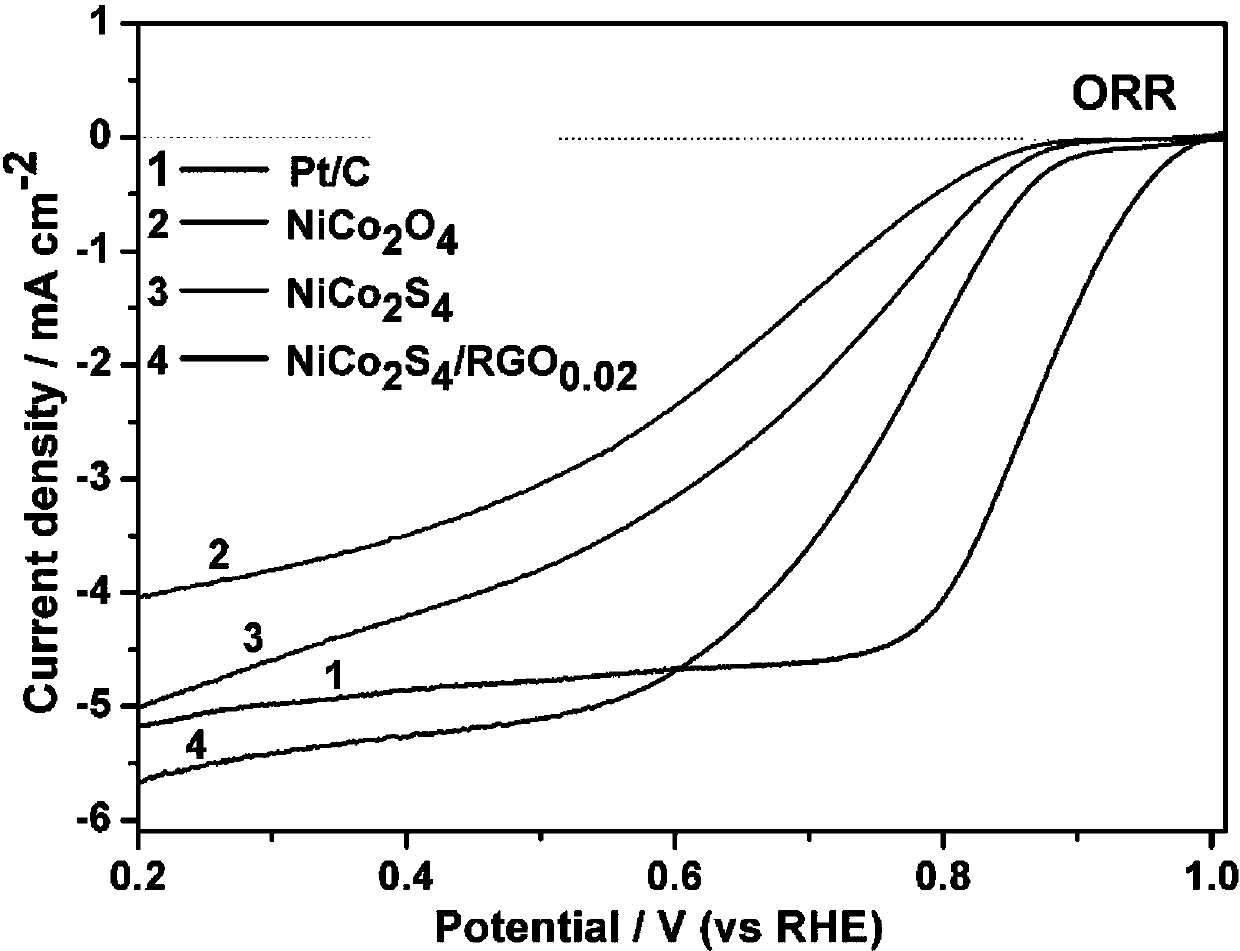

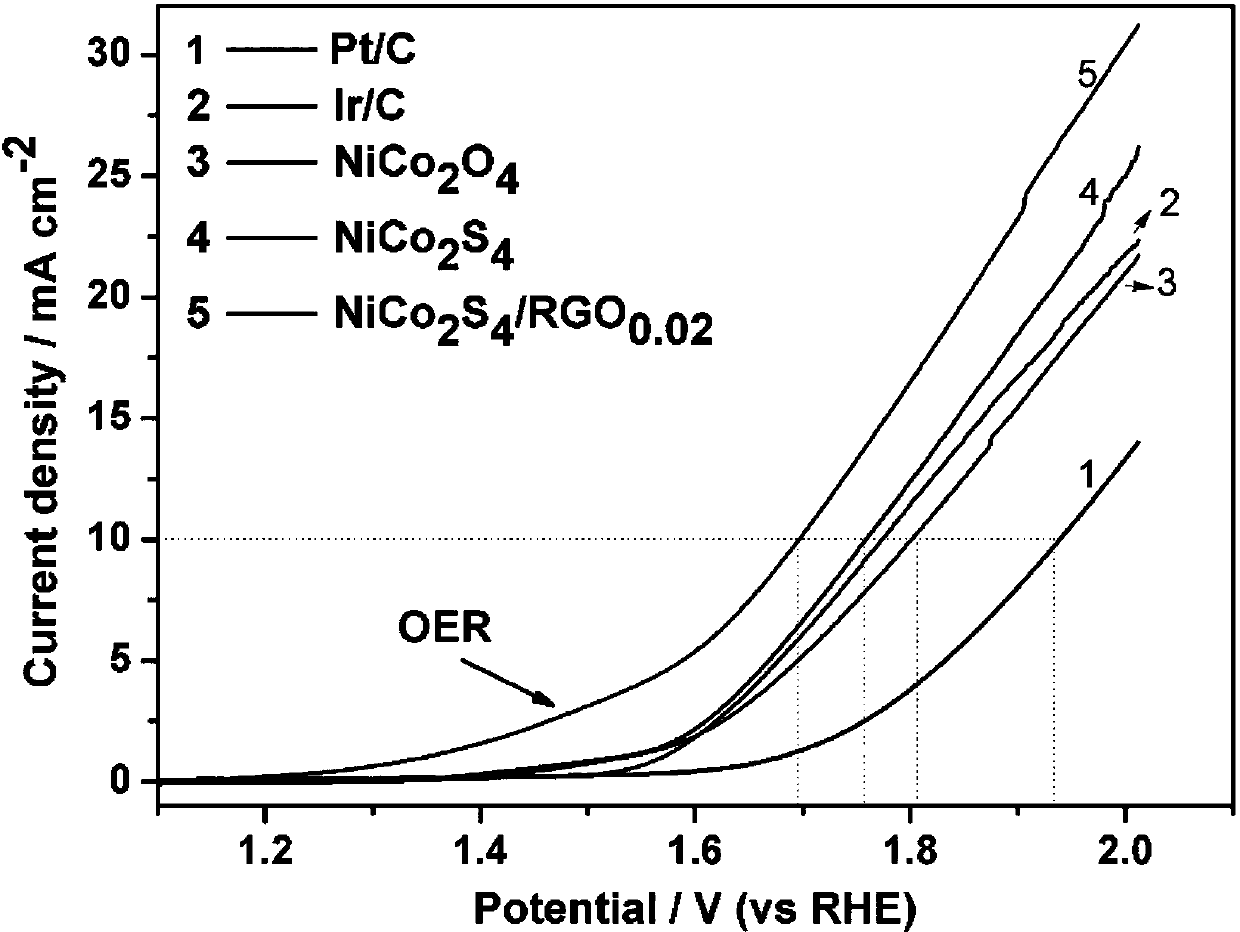

A dual-functional catalyst, nickel-cobalt sulfide technology, applied in the direction of fuel cell half-cells and secondary battery-type half-cells, battery electrodes, circuits, etc., can solve the problem of insufficient catalytic performance of electrocatalysts and achieve excellent charging Effects of discharge performance and stability, improvement of electronic conductivity, and effective ion contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of a nickel-cobalt sulfide / graphene composite material zinc-air battery bifunctional catalyst, comprising the following steps:

[0028] The first step: Weigh cobalt nitrate hexahydrate, nickel nitrate hexahydrate and urea with a mass ratio of 2:1:0.5, and dissolve them in a mixed solution of distilled water and isopropanol, the volume ratio of distilled water and isopropanol 1:3, the above mixed solution was stirred evenly, and ultrasonically dispersed for 1 hour; then the resulting mixture was transferred to an autoclave and sealed, and reacted in an environment of 140°C for 12 hours. After the autoclave was naturally cooled to room temperature, the resulting precipitate was collected. The material was washed three times with distilled water and absolute ethanol, and then vacuum-dried at 70°C for 8-12 hours; then, calcined at 450°C for 3 hours, cooled naturally to room temperature, and ground into powder to obtain NiCo 2 o 4 Precursor;

[0029] Ste...

Embodiment 2

[0036] The first step: take by weighing cobalt nitrate hexahydrate, nickel nitrate hexahydrate and urea with a mass ratio of 2:1:0.5, and dissolve it in a mixed solution of distilled water and isopropanol, the volume ratio of distilled water and isopropanol is 1:3, the above mixed solution was stirred evenly, ultrasonically dispersed for 1 hour, then the resulting mixture was transferred to an autoclave and sealed, and reacted at 140°C for 8, 10, 12, and 14 hours. After the autoclave was naturally cooled to room temperature, collected The resulting precipitate was washed three times with distilled water and absolute ethanol, and dried in vacuum at 70°C for 8-12 hours; after drying, it was calcined at 450°C for 3 hours; after natural cooling to room temperature, it was ground into powder to obtain NiCo 2 o 4 Precursor.

[0037] Step 2: Weigh the precursor NiCo with a mass ratio of 1:4:0.05 2 o 4 , sodium sulfide nonahydrate and graphene, dissolved in distilled water; after s...

Embodiment 3

[0040] Preparation method of nickel-cobalt sulfide / graphene composite zinc-air battery bifunctional catalyst with different mass ratios:

[0041] The first step: take by weighing cobalt nitrate hexahydrate, nickel nitrate hexahydrate and urea with a mass ratio of 2:1:0.5, and dissolve it in a mixed solution of distilled water and isopropanol, the volume ratio of distilled water and isopropanol is 1:3, the above mixed solution was stirred evenly, ultrasonically dispersed for 1 hour, then the resulting mixture was transferred to an autoclave and sealed, and reacted at 140°C for 12 hours. After the autoclave was naturally cooled to room temperature, the resulting precipitate was collected and washed with distilled water After washing with absolute ethanol for 3 times, vacuum-dry at 70°C for 8-12 hours; after drying, calcinate at 450°C for 3 hours, cool naturally to room temperature and grind into powder to obtain NiCo 2 o 4 Precursor;

[0042] Step 2: Weigh the precursor NiCo w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com