A simultaneous laser heat treatment method for laser additive manufacturing of nickel-based superalloys

A nickel-based superalloy, laser heat treatment technology, applied in the direction of additive manufacturing, additive processing, energy efficiency, etc., can solve the problem of the influence of the base material area of the forging, to improve the mechanical properties, enhance the coordinated deformation ability of the material, and reduce the stress concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation process of the nickel-based superalloy specifically includes the following processes:

[0039](1) Put the GH4169 superalloy spherical powder with a particle size of -80 to +325 mesh into the powder feeder, or put the GH4169 wire into the wire feeder.

[0040] (2), put the substrate or the repaired part into the atmospheric environment or an argon-filled inert atmosphere processing room, and fix it on the workbench; when the substrate is selected, the substrate is made of carbon steel, stainless steel or a superalloy; when the substrate is a superalloy, it is preferably Forging GH4169 superalloy; when an argon-filled inert atmosphere is used, the inlet and outlet of the argon-filled inert atmosphere processing chamber are opened, and the additive manufacturing of GH4169 superalloy starts after the argon gas is replaced until the oxygen content is below 100ppm.

[0041] When argon is replaced, high-purity argon with a purity greater than or equal to 99.99%...

Embodiment 1

[0052] (1) Put the GH4169 superalloy spherical powder with a particle size of -80 to +325 mesh into the powder feeder;

[0053] (2) Fix the forged GH4169 superalloy substrate on the workbench in the atmospheric environment;

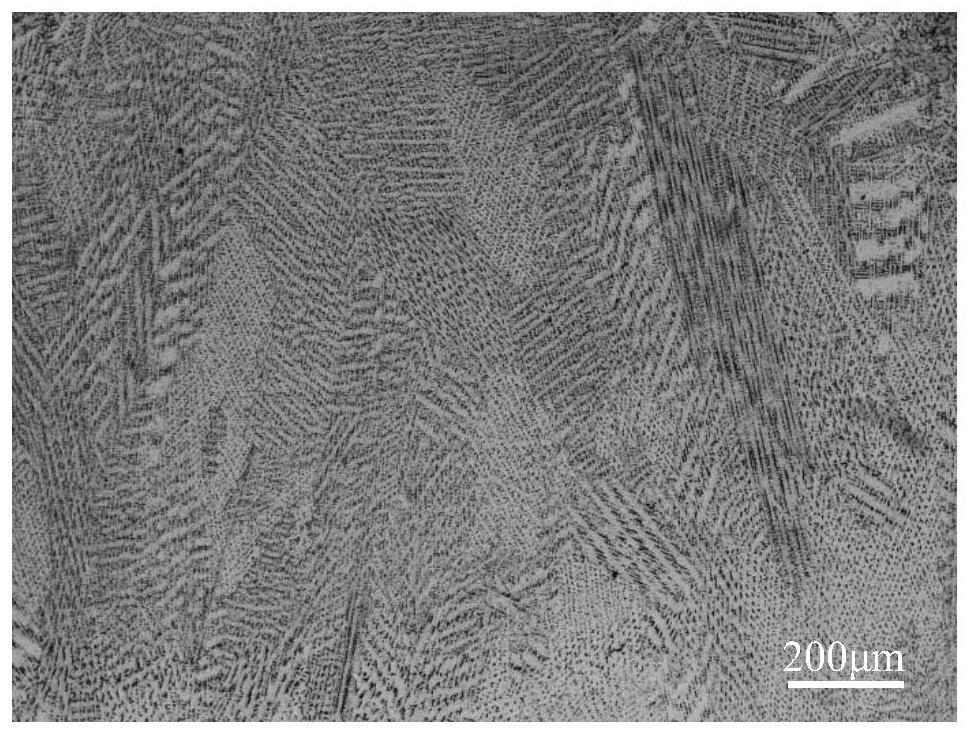

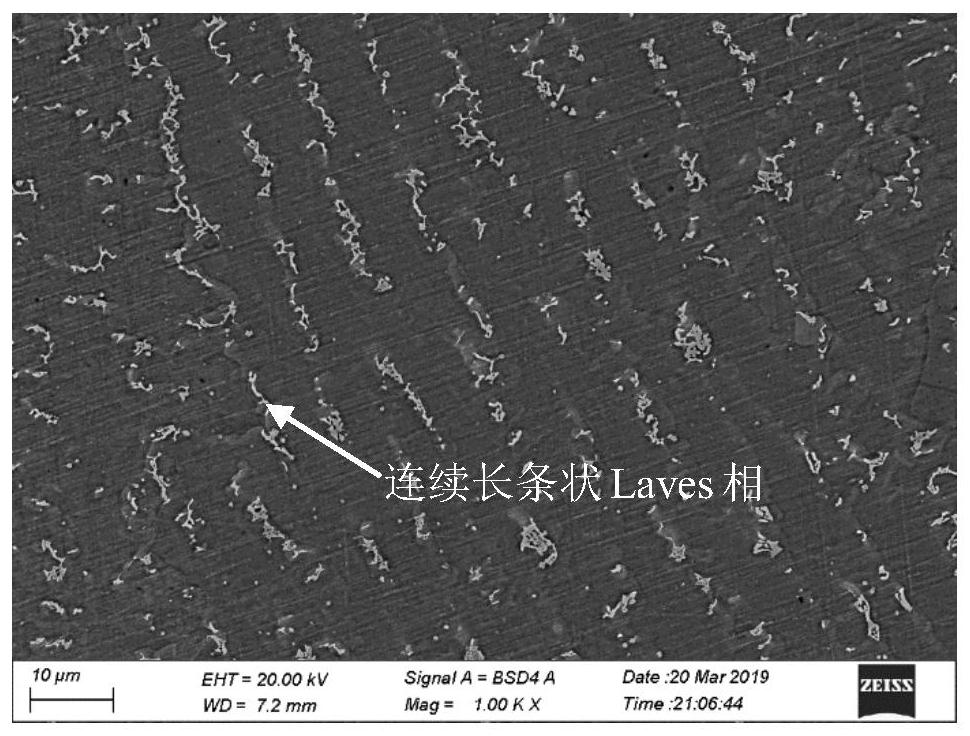

[0054] (3) The laser heat source fiber laser is introduced, and the laser additive manufacturing process parameters are: laser cladding power 700W, spot diameter 1mm, powder feeding rate 9g / min, lap rate 50%, scanning speed 8mm / s. The CNC system is used to synchronously open the powder feeder to transport GH4169 superalloy powder; prepare a GH4169 superalloy part with a height of 2.8mm and retain the Laves phase, and its microstructure is as follows figure 1 with figure 2 shown; figure 1 It shows that the as-deposited structure is dominated by columnar crystals that grow epitaxially along the deposition direction. from figure 2 It can be seen from the figure that there are a large number of Laves phases with continuous strips and irregular shapes in...

Embodiment 2

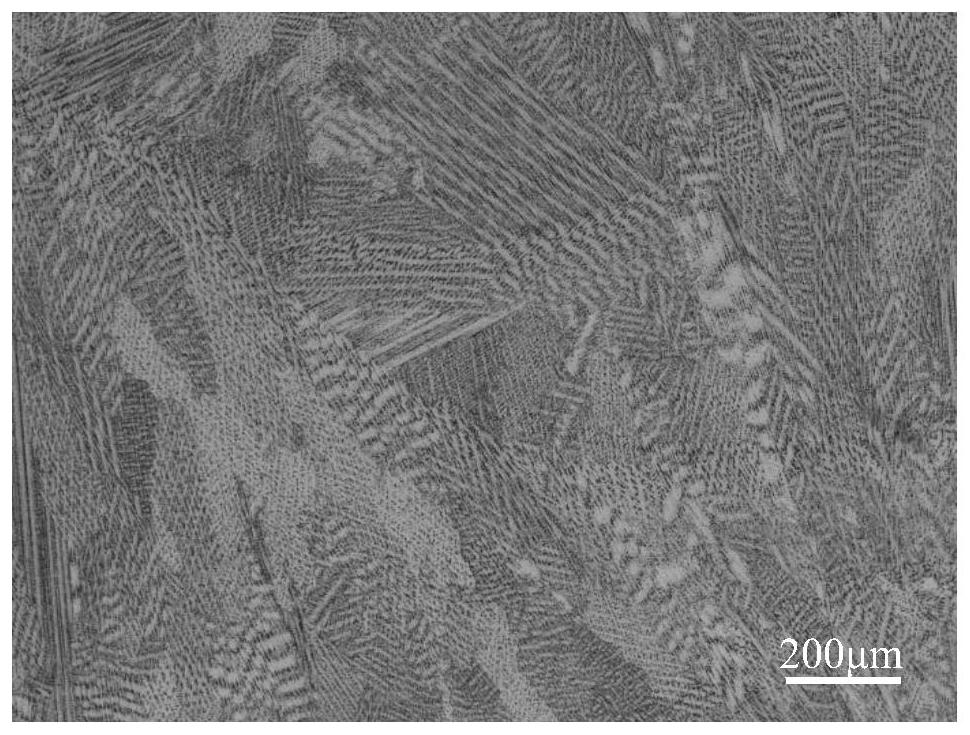

[0060] The process parameters of laser heat treatment are: laser power 200W, spot diameter 1mm, scan rate 20mm / s, laser beam is used to continuously scan the GH4169 superalloy parts with Laves phase for 3min, and the Laves phase volume fraction of the overall sample is 1.36%. Compared with the state, it is 60.58% lower. The microstructural characteristics of the obtained GH4169 superalloy after heat treatment are as follows: Figure 7 , Figure 8 , Figure 9 shown. Figure 7 The grain morphology of its macroscopic morphology has not changed significantly, and the columnar crystals that grow epitaxially along the deposition direction are still the main ones. Figure 8 The Laves phase size and volume fraction are shown to be further reduced. Figure 9 It shows that after laser heat treatment, the strengthening phase γ”+γ’ phase inside the forging base material is diffusely distributed in the matrix without dissolution.

[0061] All the other unrelated steps are the same as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com