A nanoframe material for the adsorption of hydrogen sulfide gas

A frame material, hydrogen sulfide technology, applied in the direction of gas fuel, fuel, other chemical processes, etc., can solve the problems of low adsorption capacity, complicated process, secondary pollution, etc., and achieve the effect of high adsorption efficiency, simple operation, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

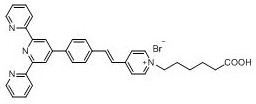

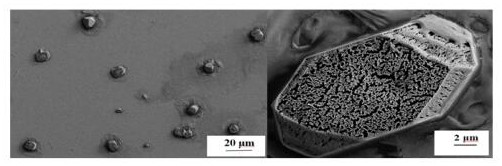

[0030] Example 1: A nano-frame material used to adsorb hydrogen sulfide gas is prepared by the following method: firstly, concentrated nitric acid or concentrated hydrochloric acid is dissolved in water to prepare an acidic aqueous solution with a pH value of 3; then the structural formula is as attached figure 1 Add the compound Z shown in the acidic aqueous solution, and then add mercuric perchlorate or mercuric chloride into the acidic aqueous solution according to the molar ratio of compound Z: mercuric perchlorate or mercuric chloride as 1:2 until the precipitation does not occur again, and then Filter and freeze-dry the precipitate at -80°C for 3 hours.

Embodiment 2

[0031] Example 2: A nano-frame material used to adsorb hydrogen sulfide gas is prepared by the following method: firstly, concentrated nitric acid or concentrated hydrochloric acid is dissolved in water to prepare an acidic aqueous solution with a pH value of 2; then the structural formula is as attached figure 1 The shown compound Z is added in the acidic aqueous solution, and then mercuric perchlorate or mercuric chloride is added in the acidic aqueous solution at a molar ratio of 1:1 by compound Z: mercuric perchlorate or mercuric chloride until the precipitation does not occur again, and then Filter and freeze-dry the precipitate at -70°C for 1 h.

Embodiment 3

[0032] Example 3: A nano-frame material used to adsorb hydrogen sulfide gas is prepared by the following method: firstly, concentrated nitric acid or concentrated hydrochloric acid is dissolved in water to prepare an acidic aqueous solution with a pH value of 4; then the structural formula is as attached figure 1 The shown compound Z is added in the acidic aqueous solution, and then mercuric perchlorate or mercuric chloride is added in the acidic aqueous solution at a molar ratio of 1:3 of compound Z: mercuric perchlorate or mercuric chloride until the precipitation does not occur again, and then Filter and freeze-dry the precipitate at -90°C for 5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com