Glass fiber reinforcement polypropylene composite material and preparation method thereof

A glass fiber and composite material technology, applied in the field of glass fiber reinforced polypropylene composite material and its preparation, can solve the problems of low tensile strength, flexural strength and impact strength, unsatisfactory mechanical properties, and high cost, and can achieve Enhanced controllability, enhanced mechanical properties, enhanced effect of interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

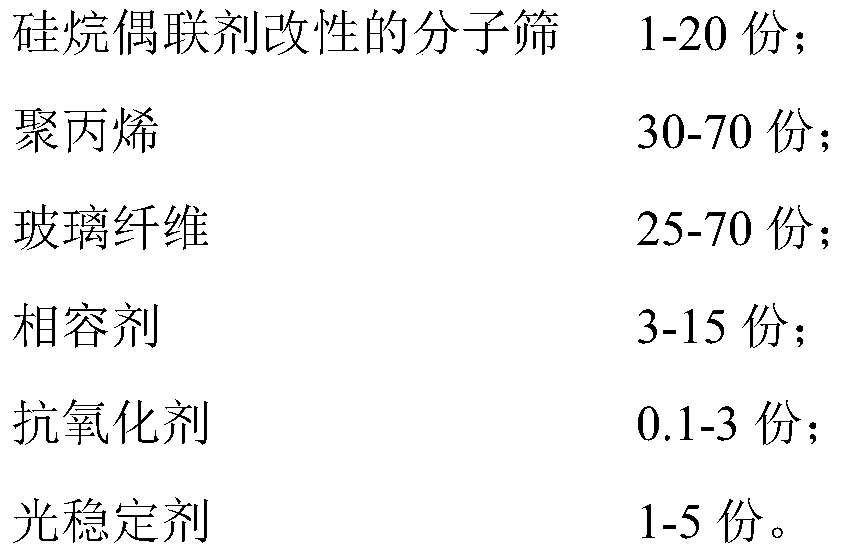

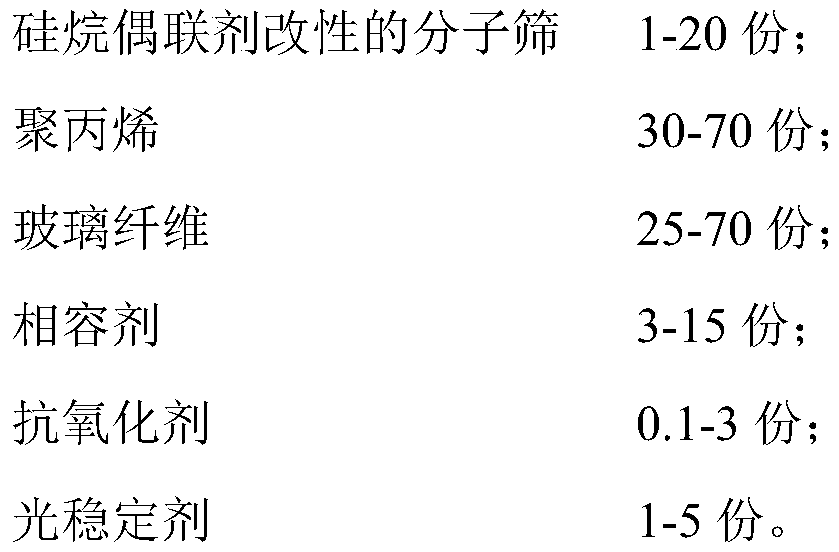

Method used

Image

Examples

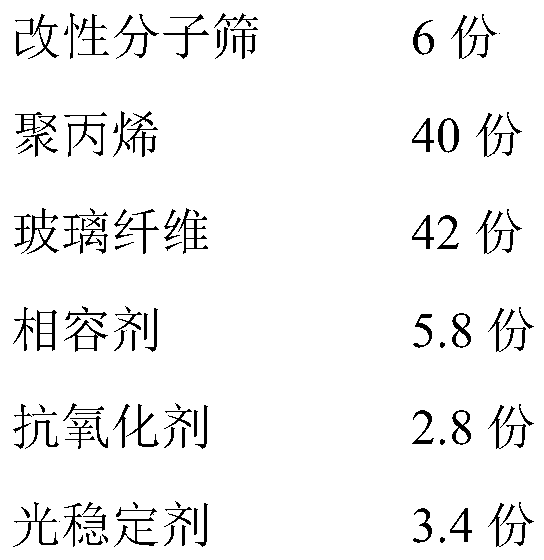

Embodiment 1

[0058]

[0059] Molecular sieves are made of 20 parts of deionized water, 1.2 parts of sodium hydroxide, 0.3 parts of sodium metaaluminate, 16 parts of organic template, 30 parts of boric acid, and 32.5 parts of silica sol, and then react in a homogeneous reactor at 170 ° C for 7 days , prepared under the condition that the rotational speed is 10 rpm. Afterwards, it was calcined at 560°C for 20 hours, and put into a desiccator for use. The molecular sieve prepared in this example is a MWW type molecular sieve.

[0060] The modified molecular sieve is prepared by refluxing the toluene solution of the above-mentioned dried molecular sieve with a silane coupling agent γ-aminopropyltriethoxysilane (KH550) at 120° C. for 10 hours, washing and drying.

[0061] Polypropylene is copolymerized polypropylene, the melt flow rate is 40g / 10min, the test condition is 230°C, 2.16kg

[0062] The glass fiber is continuous alkali-free glass fiber with a fiber diameter of 17 microns and a l...

Embodiment 2

[0068]

[0069] Molecular sieve is composed of 19 parts of deionized water, 1 part of sodium hydroxide, 1.2 parts of sodium metaaluminate, 18.8 parts of organic template, 25 parts of boric acid, and 35 parts of silica sol, and then react in a homogeneous reactor at 150 ° C for 5 days , prepared under the condition that the rotational speed is 15 rpm. After that, it was calcined at 580°C for 10 hours, and put into a desiccator for use. The molecular sieve prepared in this example is an MFI type molecular sieve.

[0070] The modified molecular sieve is prepared by refluxing the toluene solution of the above-mentioned dried molecular sieve with a silane coupling agent γ-aminopropyltriethoxysilane (KH550) at 120° C. for 10 hours, washing and drying.

[0071] Polypropylene is copolymerized polypropylene, the melt flow rate is 40g / 10min, the test condition is 230°C, 2.16kg

[0072] The glass fiber is continuous alkali-free glass fiber with a fiber diameter of 17 microns and a l...

Embodiment 3

[0078]

[0079] Molecular sieves are made of 30 parts of deionized water, 1.2 parts of sodium hydroxide, 1.4 parts of sodium metaaluminate, 13.8 parts of organic template, 13.6 parts of boric acid, and 40 parts of silica sol, and then react in a homogeneous reactor at 170 ° C for 7 days , prepared under the condition that the rotational speed is 10 rpm. After that, it was calcined at 580°C for 20 hours, and put into a desiccator for use. The molecular sieve prepared in this example is mordenite molecular sieve.

[0080] The modified molecular sieve is prepared from the toluene solution of the dried molecular sieve using silane coupling agent γ-aminopropyltriethoxysilane (KH550) at 125° C. for 12 hours, washed and dried.

[0081] Polypropylene is copolymerized polypropylene, the melt flow rate is 40g / 10min, the test condition is 230°C, 2.16kg

[0082] The glass fiber is continuous alkali-free glass fiber with a fiber diameter of 0.17 microns and a linear density of 1200tex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com