Preparation method of yellow corrosion-resistant ceramic membrane grown in situ on surface of aluminum matrix composite material

An aluminum-based composite material and in-situ growth technology, which is applied in the direction of surface reaction electrolytic coating, electrolytic coating, anodic oxidation, etc., can solve the problems such as the preparation method of corrosion-resistant micro-arc oxidation yellow ceramic film that is not publicly reported in the literature, and achieve improvement The effect of uniform hardness and color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

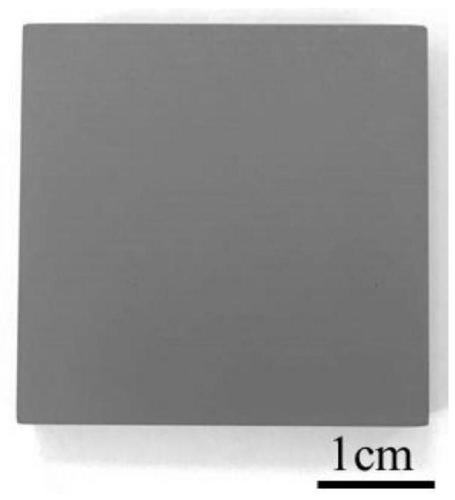

[0036] 1) Choose 7050 aluminum-based composite material (size 30mm×30mm×5mm) and use 180#, 320#, 800#, 1200# metallographic sandpaper to roughly grind and finely grind the aluminum-based composite material matrix to completely remove the surface oxide film , and then put it into acetone for ultrasonic cleaning for 5 minutes, degrease the surface of the polished substrate, and finally clean it with deionized water, and dry the cleaned aluminum-based composite material with a hair dryer for later use.

[0037] 2) Prepare the electrolyte: Use a graduated cylinder to measure 2L of deionized water and pour it into the micro-arc oxidation tank. Weigh 18g of sodium silicate with a concentration of 9g / L, 8g of sodium hydroxide with a concentration of 4g / L, and 4g of sodium hydroxide with a concentration of 2g. / L of disodium edetate and 6 g of potassium permanganate with a concentration of 3 g / L were added to deionized water in sequence, and stirred continuously during the addition to ...

Embodiment 2

[0042] 1) Choose 7050 aluminum-based composite material (size 30mm×30mm×5mm) and use 180#, 320#, 800#, 1200# metallographic sandpaper to roughly grind and finely grind the aluminum-based composite material matrix to completely remove the surface oxide film , and then put it into acetone for ultrasonic cleaning for 5 minutes, degrease the surface of the polished substrate, and finally clean it with deionized water, and dry the cleaned aluminum-based composite material with a hair dryer for later use.

[0043] 2) Prepare the electrolyte: use a graduated cylinder to measure 2L of deionized water and pour it into the micro-arc oxidation tank, weigh 24g of sodium silicate with a concentration of 12g / L, 12g of sodium hydroxide with a concentration of 6g / L, and 8g of sodium hydroxide with a concentration of 4g / L of disodium edetate and 10 g of potassium permanganate with a concentration of 5 g / L were added to deionized water in sequence, and stirred continuously during the addition t...

Embodiment 3

[0049] 1) Choose 7050 aluminum-based composite material (size 30mm×30mm×5mm) and use 180#, 320#, 800#, 1200# metallographic sandpaper to roughly grind and finely grind the aluminum-based composite material matrix to completely remove the surface oxide film , and then put it into acetone for ultrasonic cleaning for 5 minutes, degrease the surface of the polished substrate, and finally clean it with deionized water, and dry the cleaned aluminum-based composite material with a hair dryer for later use.

[0050] 2) Prepare the electrolyte: use a graduated cylinder to measure 2L of deionized water and pour it into the micro-arc oxidation tank, weigh 10g of sodium silicate with a concentration of 5g / L, 4g of sodium hydroxide with a concentration of 2g / L, and 1g of sodium hydroxide with a concentration of 0.5 g / L disodium edetate and 3 g potassium permanganate with a concentration of 1.5 g / L were added to deionized water in sequence, and stirred continuously during the addition to ful...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

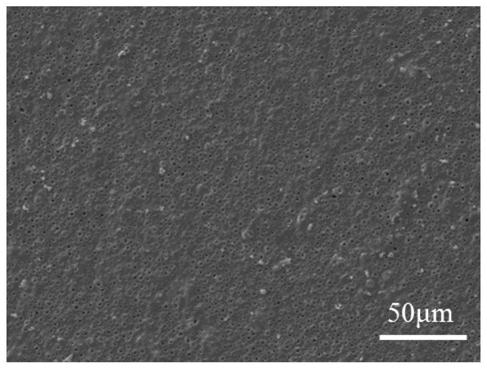

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com