Argon arc welding process of a super austenitic stainless steel 254smo steel pipe

A technology of austenitic stainless steel and welding technology, applied in welding equipment, welding equipment, welding accessories, etc., can solve problems affecting the performance of welded joints, intergranular chromium deficiency, intergranular corrosion, etc., and achieve excellent resistance to stress corrosion cracking Effects on performance, churn reduction, improved performance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

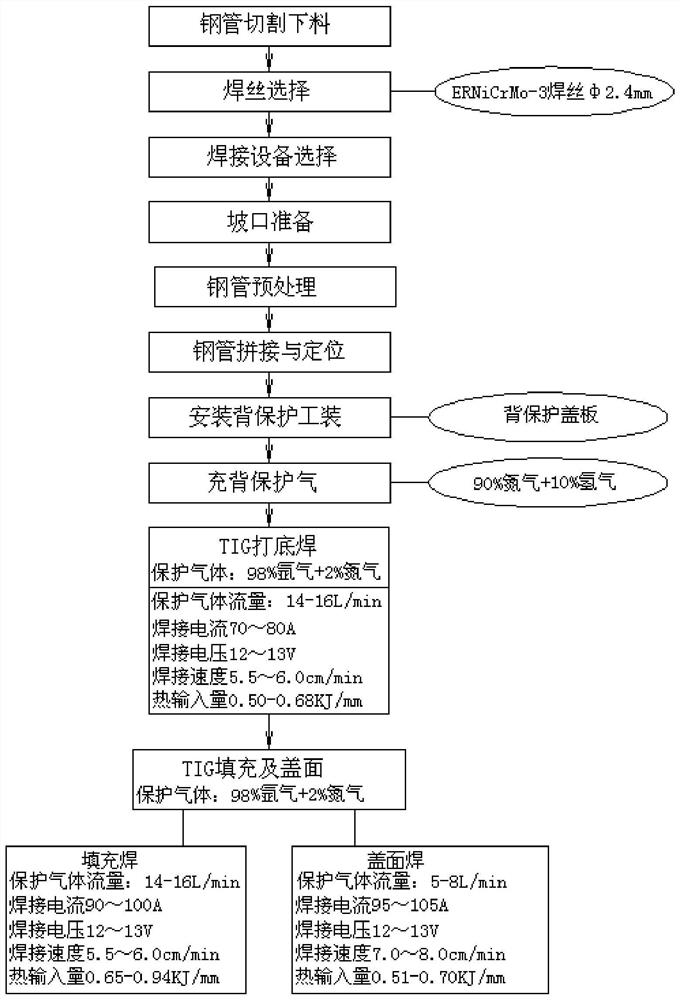

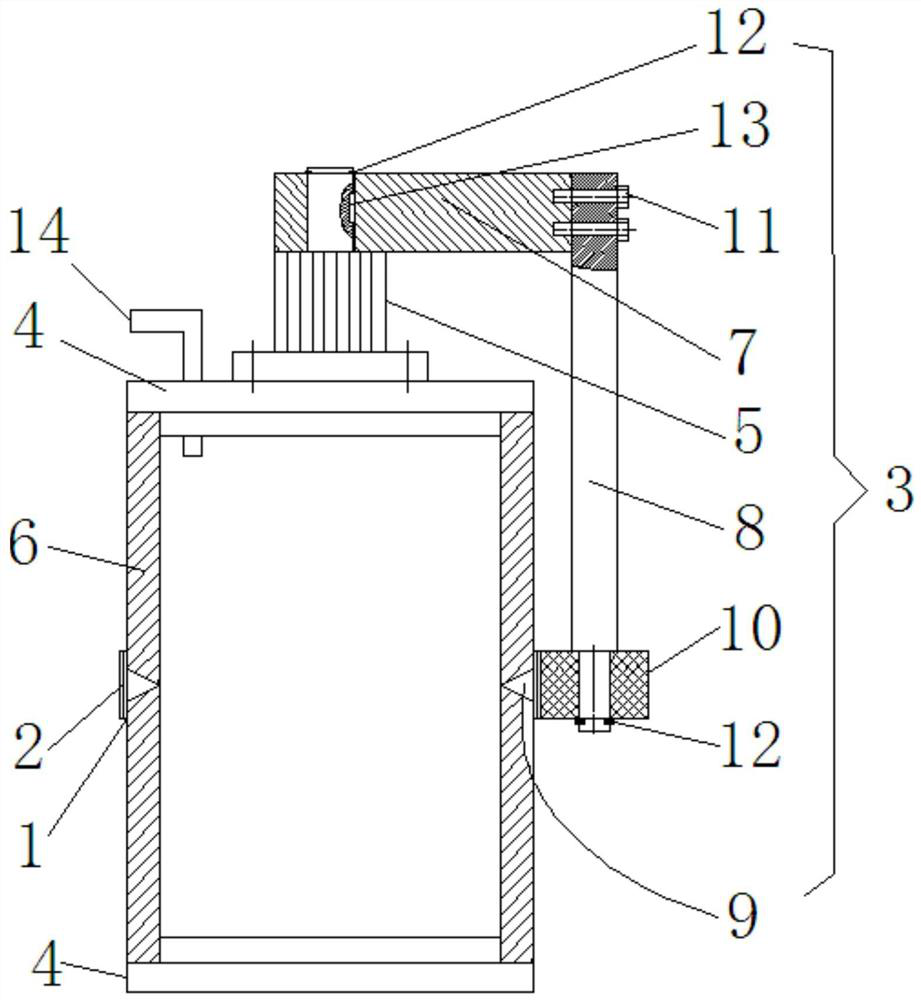

[0048] Such as Figures 1 to 3 Shown is the embodiment of the argon arc welding process of a kind of super austenitic stainless steel 254SMo steel pipe of the present invention, comprises following process steps:

[0049] (1) Steel pipe cutting and blanking: 254SMo stainless steel pipes are used, which are cut and formed according to the design requirements;

[0050] (2) Selection of welding wire: use AWSA5.14: ERNiCrMo-3, welding wire with a diameter of φ2.4mm;

[0051] (3) Selection and setting of welding equipment: use TIG welding machine and matching TIG welding torch, set the polarity of the power supply to DC positive connection, the type of tungsten electrode of the TIG welding torch is cerium tungsten electrode WCe-20, and the diameter is φ2.4mm; TIG welding torch The nozzle uses a nozzle with an inner diameter of 16mm;

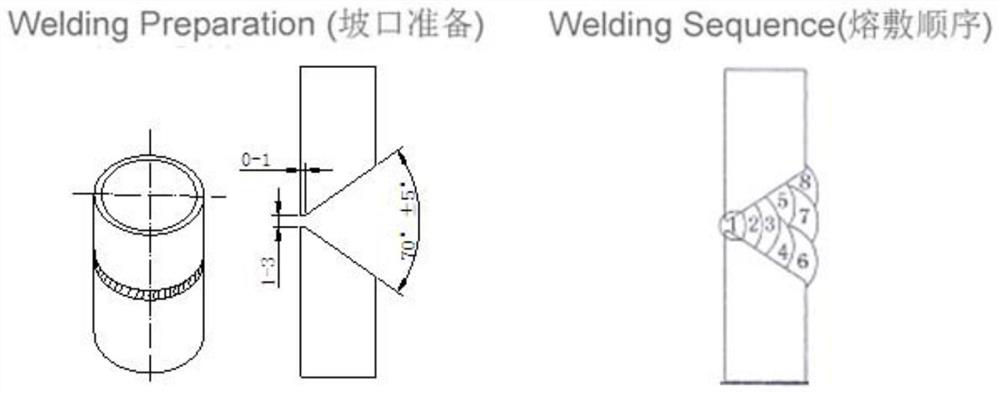

[0052] (4) Groove preparation: make a welding groove at the butt joint of the stainless steel pipe, the welding groove adopts a butt V-shaped groov...

Embodiment 2

[0077] Adopt the welding process of embodiment 1, carry out the butt welding test of super austenitic stainless steel 254SMo steel pipe, the welding sample is processed according to the sample size requirement of corresponding inspection standard, with American Bureau of Shipping (ABS) material and welding specification as guidance Documents, the following items are tested, see the table below:

[0078]

[0079]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com