Abrasion-resistant steel plate excellent in stress corrosion cracking resistance and manufacturing method thereof

一种制造方法、耐磨损的技术,应用在耐应力腐蚀断裂性优异的耐磨损钢板及其制造领域,能够解决耐磨损特性差、机械、装置发生故障、无法维持强度危险性等问题,达到优异耐应力腐蚀断裂性、寿命提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

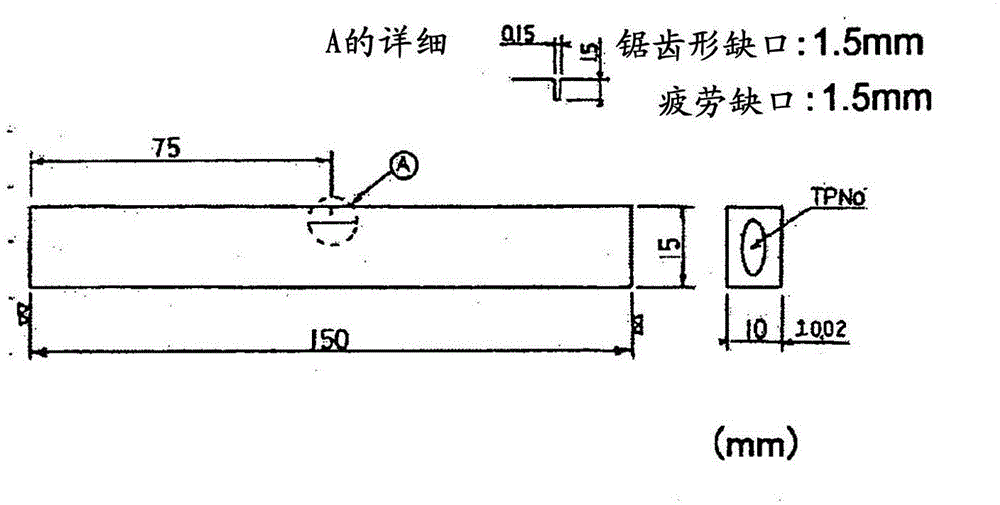

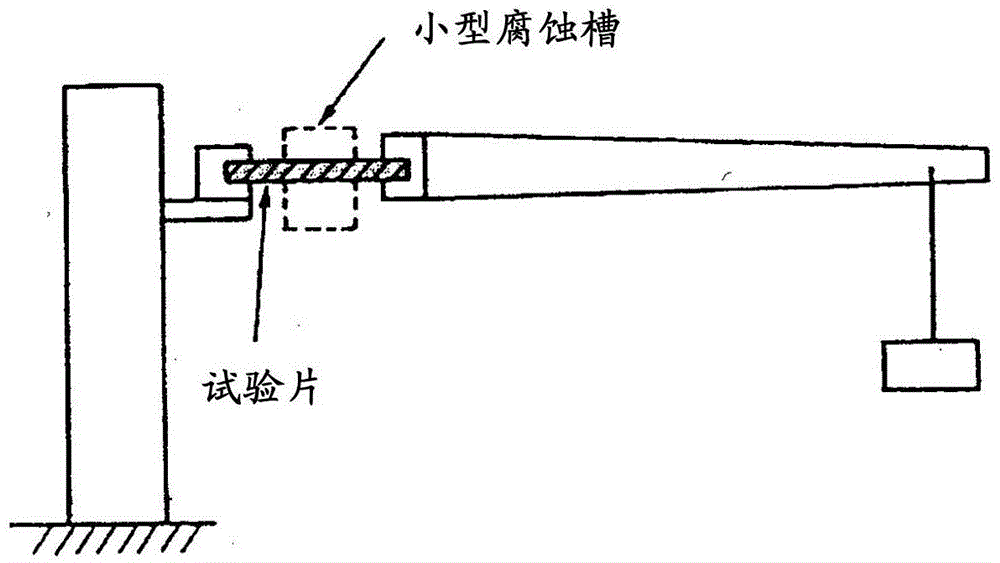

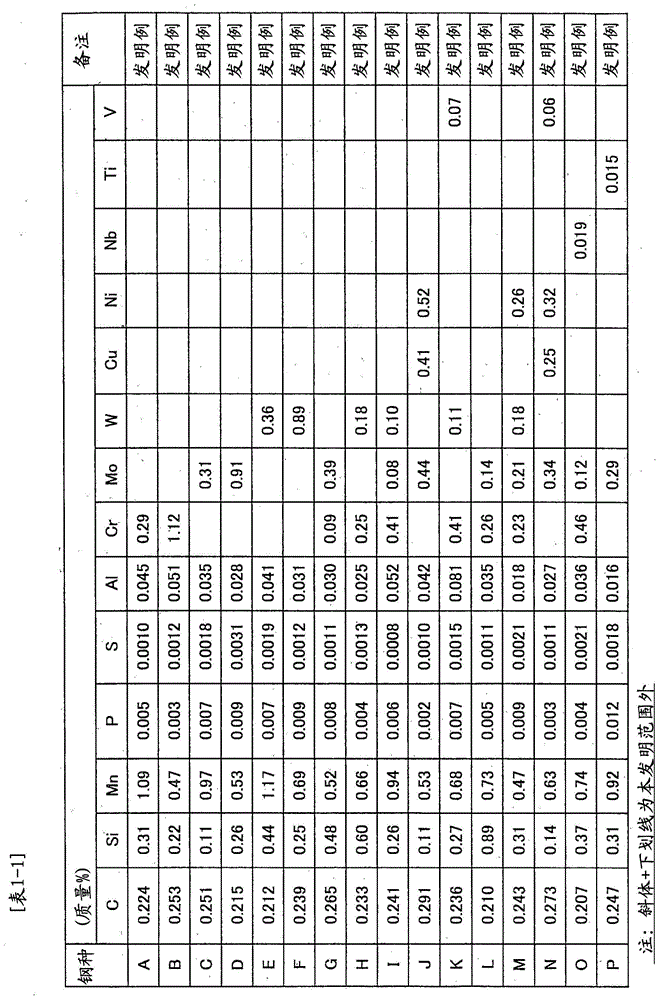

[0104] Prepare steel slabs (steelslab) with various composition shown in Table 1-1 to Table 1-4 by using a converter-ladle refining-continuous casting method, and heat it to 950 to 1250°C After that, hot rolling is performed, and some steel plates are subjected to accelerated cooling immediately after rolling, and other steel plates are subjected to air cooling after rolling. Furthermore, some steel plates are subjected to accelerated cooling and tempering after reheating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com