Copper alloy plate and manufacturing method of copper alloy plate

A technology of copper alloy plate and manufacturing method, applied in the field of copper alloy plate, capable of solving the problems of insufficient electrical conductivity and strength characteristics of Cu-Zn-Sn alloy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

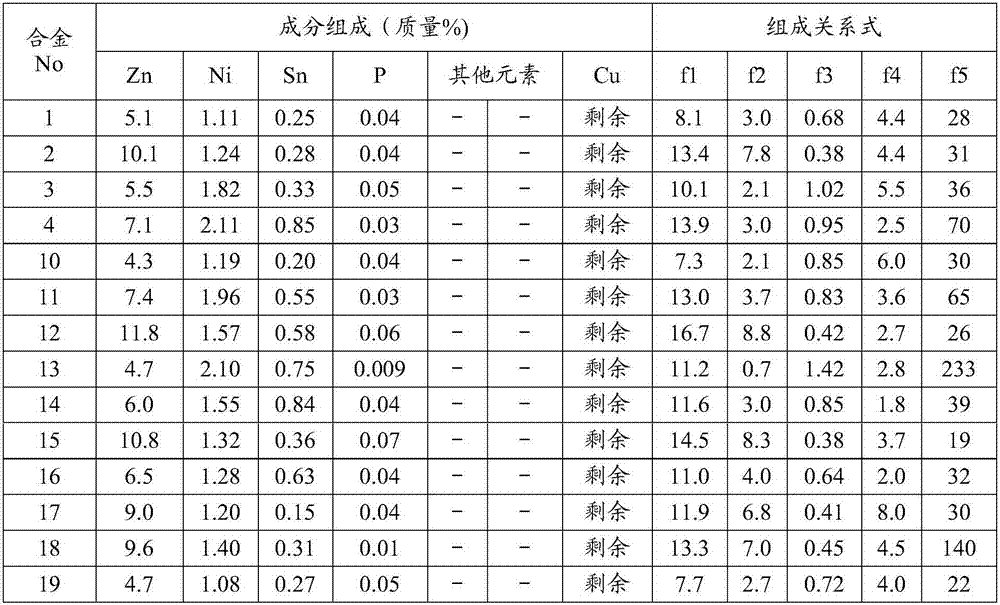

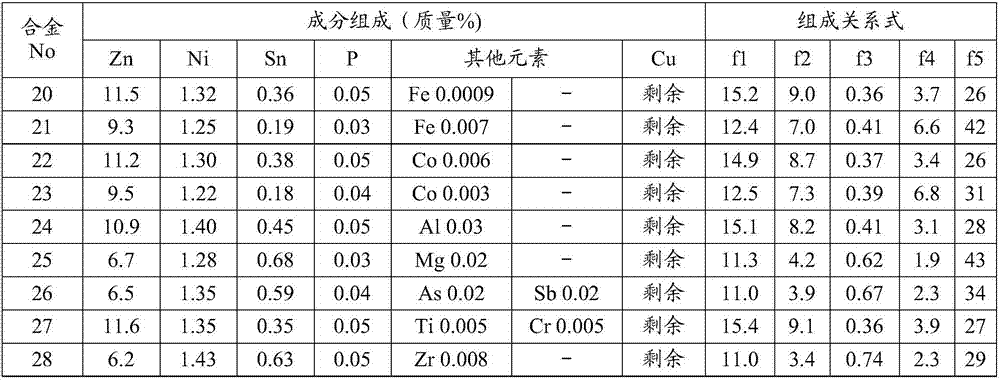

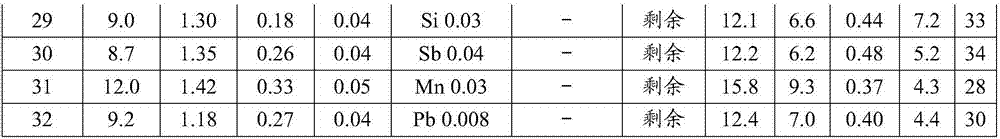

[0160] The results of confirmation experiments conducted to confirm the effects of the present invention are shown below. In addition, the following examples are used to illustrate the effects of the present invention, and the structures, processes and conditions described in the examples do not limit the technical scope of the present invention.

[0161] Using the copper alloy sheets according to the first to fourth embodiments of the present invention and the copper alloy sheets of the comparative composition described above, samples were produced by changing the manufacturing process. The composition of the copper alloy is shown in Tables 1-3. In addition, Tables 1 to 3 show the values of the composition relational expressions f1, f2, f3, f4, and f5 shown in the above-mentioned embodiment.

[0162] The manufacturing steps of the samples were performed in three types, A, B, and C, and the manufacturing conditions were changed for each manufacturing step. Manufacturing pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com