Polyimide-based traction belt

A technology of polyimide-based traction and polyimide resin, which is applied in the field of traction belts, can solve the problems of restricting the application of composite material traction belts, low heat resistance level, poor mechanical properties and environmental adaptability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Prepare polyimide resin according to the following method

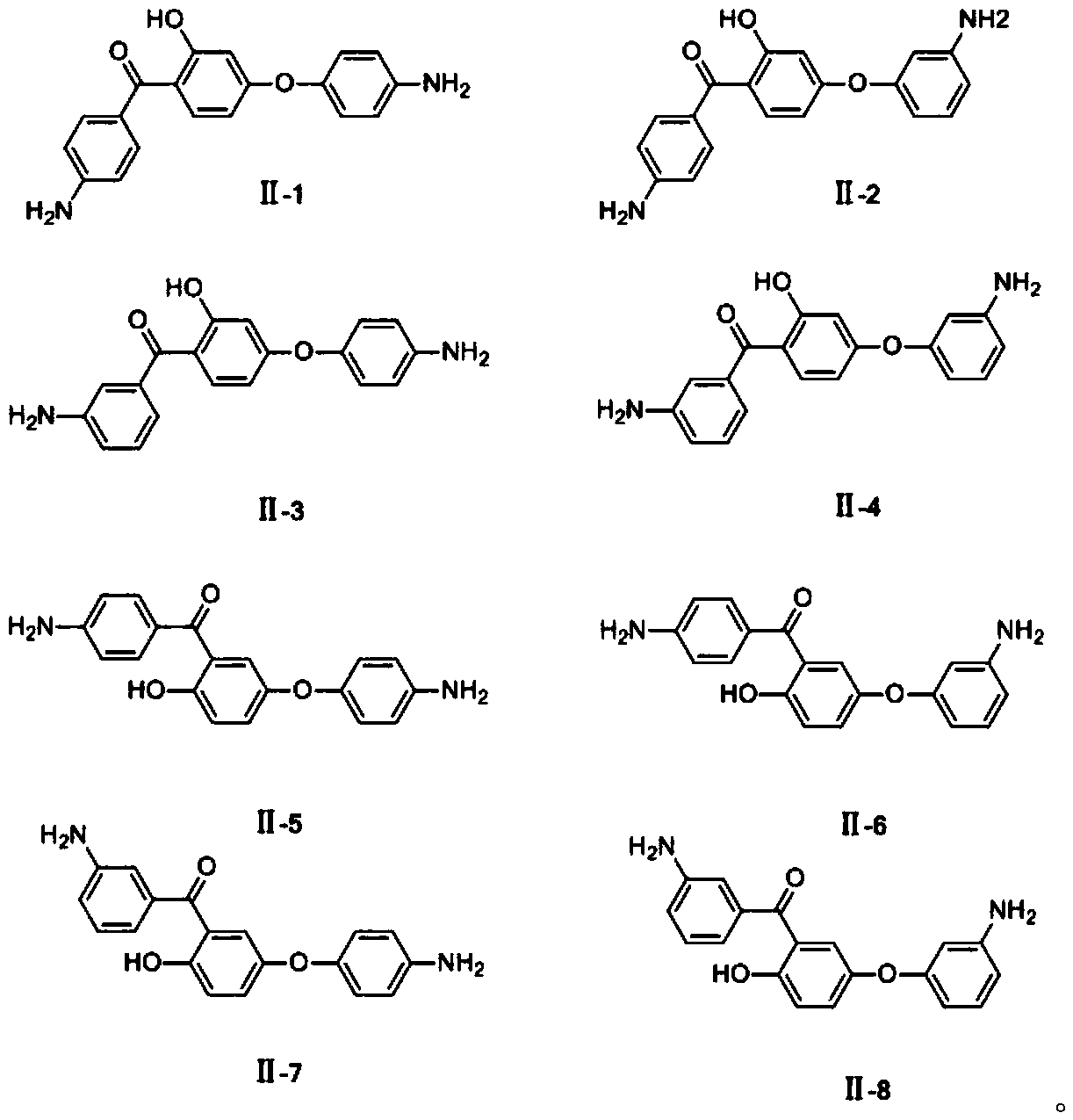

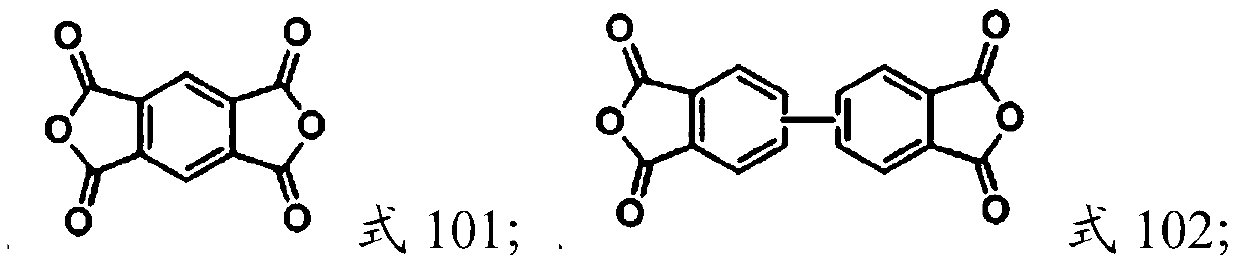

[0075] Add 4.997kg (9.6mol) of bisphenol A diether dianhydride and 0.973kg (9mol) of m-phenylenediamine to a 100-liter reactor equipped with mechanical stirring, nitrogen protection, water and condensing reflux device, formula II- 0.32 kg (1 mol) of diamine with the structure shown in 1, 0.118 kg (0.8 mol) of terephthalic anhydride, and 40 kg of N,N-dimethylacetamide (DMAc), reacted at room temperature for 12 hours to obtain a polyamic acid solution. Add 10 kg of xylene to the obtained polyamic acid solution, reflux at 160° C. with water for 5 hours, filter, wash with ethanol 4 times, and dry at 200° C. for 10 hours to finally obtain polyimide resin powder.

[0076] Composite traction belt is prepared according to the following method

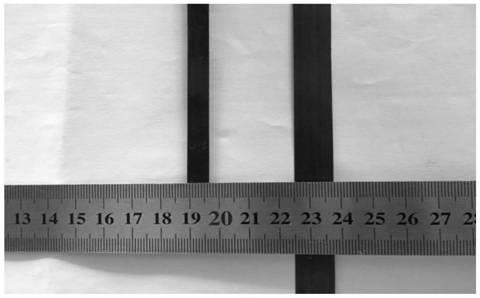

[0077] The 24k carbon fiber is drawn out from the creel shaft by the haul-off machine, spread evenly through the spreading roller, enters the impregnation tank after being preh...

Embodiment 2

[0081] Prepare polyimide resin according to the following method

[0082] Add 4.997kg (9.6mol) of bisphenol A diether dianhydride and 0.973kg (9mol) of p-phenylenediamine to a 100-liter reactor equipped with mechanical stirring, nitrogen protection, water and condensing reflux device, formula II- 0.32 kg (1 mol) of diamine with the structure shown in 4, 0.118 kg (0.8 mol) of terephthalic anhydride, and 36 kg of N,N-dimethylacetamide (DMAc) were reacted at room temperature for 12 hours to obtain a polyamic acid solution. Add 10 kg of xylene to the obtained polyamic acid solution, reflux at 165° C. with water for 5 hours, filter, wash with ethanol 4 times, and dry at 200° C. for 10 hours to finally obtain polyimide resin powder.

[0083] Composite traction belt is prepared according to the following method

[0084] The 36k carbon fiber is drawn out from the creel shaft by a haul-off machine, and the fiber is spread evenly through the spreading roller, and enters the impregnatio...

Embodiment 3

[0087] Prepare polyimide resin according to the following method

[0088] Add 4.997kg (9.6mol) of bisphenol A diether dianhydride and 0.757kg (7mol) of m-phenylenediamine to a 100-liter reactor equipped with mechanical stirring, nitrogen protection, water and condensing reflux device, formula II- 0.961 kg (3 mol) of diamine with the structure shown in 8, 0.118 kg (0.8 mol) of terephthalic anhydride, and 36 kg of N,N-dimethylacetamide (DMAc), reacted at room temperature for 12 hours to obtain a polyamic acid solution. Add 8kg of xylene to the obtained polyamic acid solution, reflux at 160°C with water for 5 hours, filter, wash with ethanol 4 times, and dry at 200°C for 10 hours to finally obtain polyimide resin powder.

[0089] Composite traction belt is prepared according to the following method

[0090] The 50k carbon fiber is drawn out from the creel shaft by the haul-off machine, and the fiber is spread evenly through the spreading roller, and enters the impregnation tank ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com