Hot-work die steel with good cutting performance and preparation method thereof

A technology of hot working die steel and cutting performance, applied in the field of metal materials, can solve problems such as poor fluidity, hazards, steel breakout, etc., and achieve the effects of excellent performance and green preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below by embodiment the present invention will be further described.

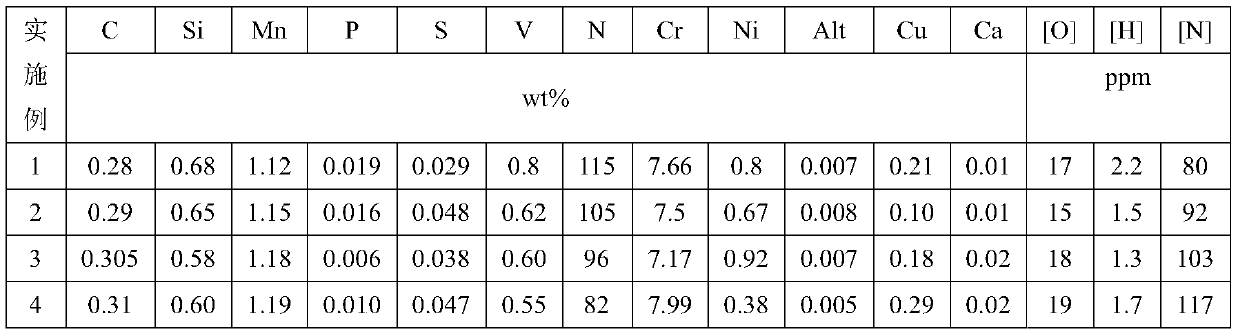

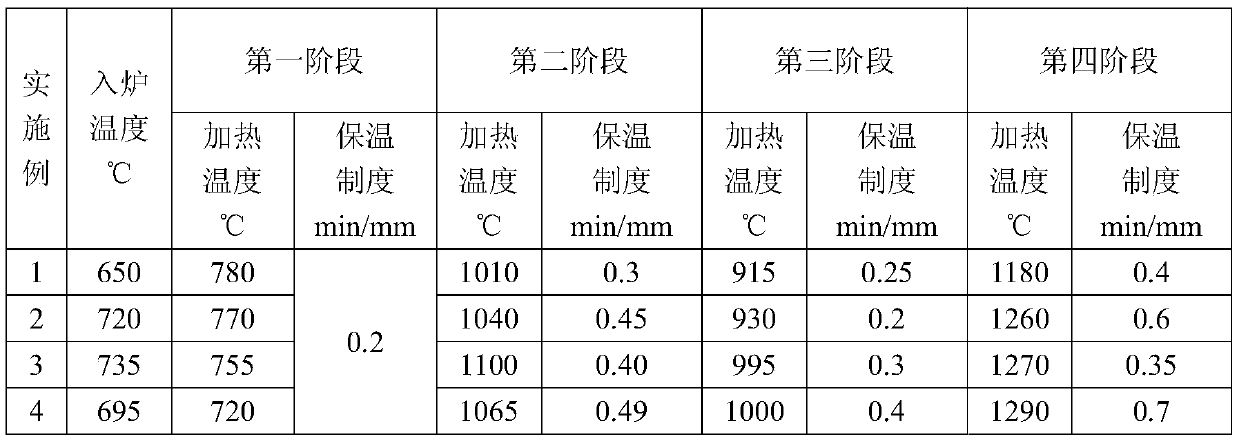

[0041] The embodiments of the present invention carry out smelting-large slab continuous casting-heating-rolling-pretreatment-normalizing+tempering according to the composition ratio of the technical proposal.

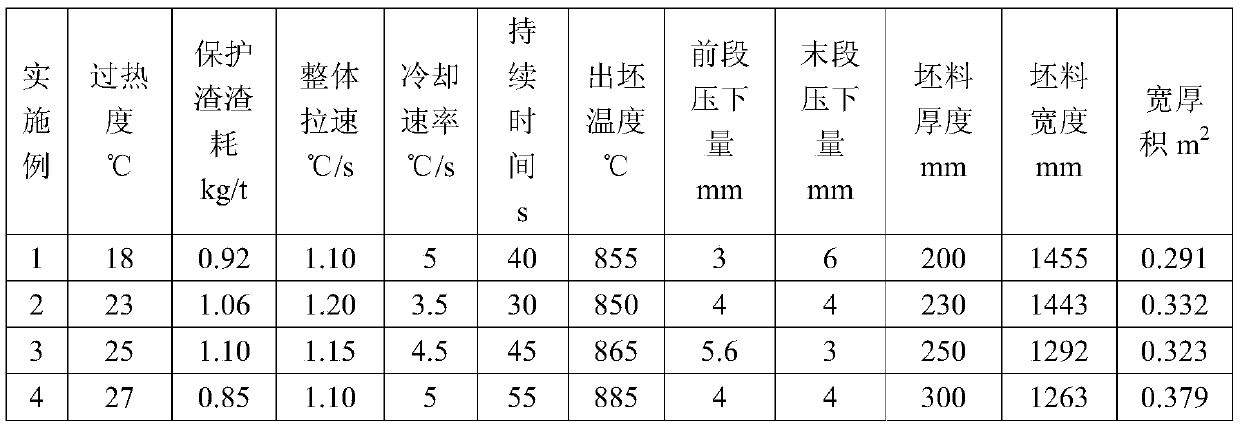

[0042] (1) Large slab continuous casting:

[0043] The continuous casting adopts superheating degree of 18-27℃. After the continuous casting slab exits the continuous casting bending section, the temperature range of the continuous casting slab is controlled at 850-890℃, the cooling rate is controlled at 2-5℃ / s, and the duration is not more than 1min;

[0044] The billet reduction is divided into two sections, the front section and the front section are controlled at 2-5mm, and the rear section is controlled at 3-5mm;

[0045] The thickness H of the large slab is controlled within 100mm≤H≤400mm, the width W of the large slab is controlled within the range of 1200mm≤W≤2000mm, and the size of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com