Preparation method of hydrophobic polymer film material

A hydrophobic polymer and membrane material technology, applied in flat products, applications, household appliances, etc., can solve problems such as long process flow, unsuitable for large-scale production, complicated process, etc., and achieve simple and controllable process and high product quality Simple and controllable, with good prospects for industrialization

Active Publication Date: 2019-09-10

EAST CHINA UNIV OF SCI & TECH

View PDF6 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Obviously, this method not only has a long and complicated process, but also needs to use a large amount of organic solvents to prepare LDPE solution and prepare LDPE film by casting method, which involves many problems such as high organic solvent recovery cost, and the size of the film is restricted by the size of the template, so it is not suitable for large-scale production.

[0012] Chinese patent CN105346146B discloses a high-density polyethylene superhydrophobic sheet / container with controllable rolling angle and its preparation method. The method first uses a press and a mold to prepare an HDPE sheet, and then puts the same two HDPE sheets on the mold Middle lamination, after cooling to room temperature, peel off the two HDPE sheets with iron tongs to obtain a super-hydrophobic HDPE sheet. Although this method is simple and easy to manufacture, and it is solvent-free, it cannot be prepared due to the size limitations of the mold and the flat vulcanizer. Continuous film or sheet, and the sheet is easily damaged when the two pieces are peeled off, which deteriorates the mechanical properties and limits the application field of this method

[0013] Chinese patent CN103341437B discloses a method for preparing a functional superhydrophobic polypropylene coating. The method is to dissolve polypropylene and other polymers in toluene organic solvent at 120-140 °C, and then add functional particles such as silicon dioxide. , it is coated on the substrate by coating method to form a superhydrophobic polypropylene coating. Although the superhydrophobic coating prepared by this method has a stable structure and good adhesion, it uses a large amount of harmful organic solvents such as toluene, which is subject to Environmental constraints, not suitable for promotion and application

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

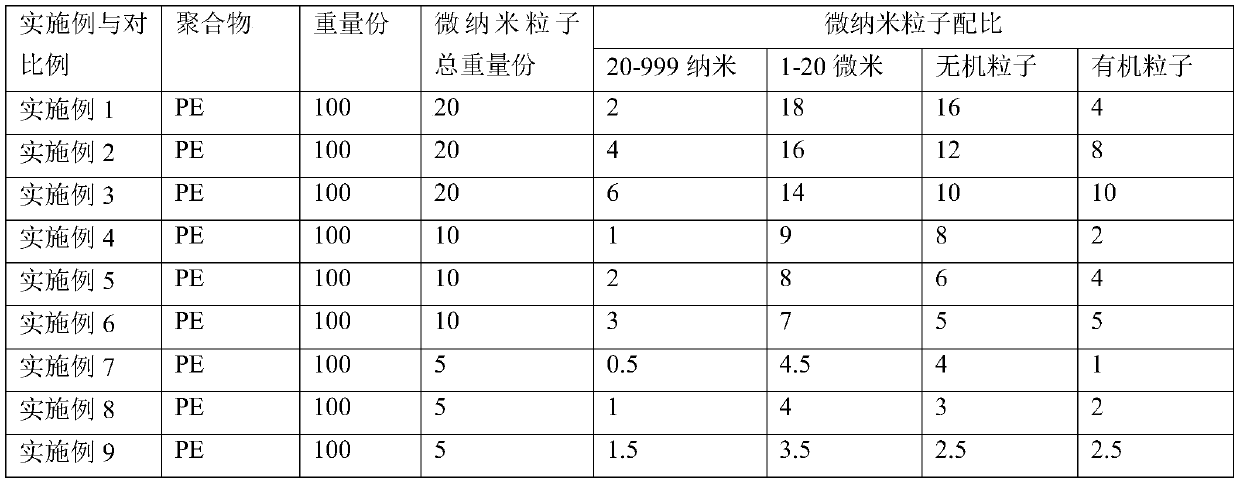

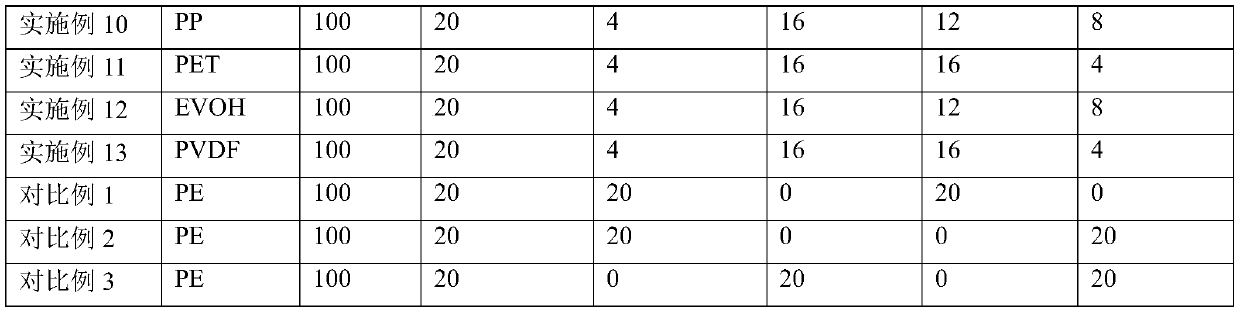

Embodiment 1-13 and comparative example 1-3

[0041] Table 1: Proportions for preparing hydrophobic polymer membrane materials

[0042]

[0043]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

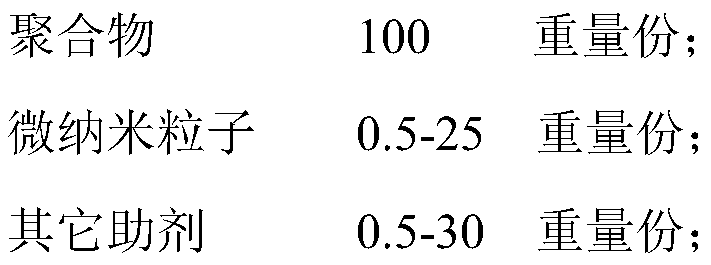

The invention provides a preparation method of a hydrophobic polymer film material. The material comprises the following components in parts by weight: 100 parts of a polymer; 0.5-25 parts of micro-nano particles; and 0.5-30 parts of other auxiliary agents. The preparation step comprises: melt-mixing the polymer, the micro-nano particles and the other auxiliary agents, performing extrusion, calendering or tape casting to form a film blank, and then performing stretching; and forming micro-nano protrusions and cavity rough surface structures after stretching to obtain the hydrophobic polymer film material. The water contact angle of the material is 120 degrees or more, and the rolling angle is 15 degrees or less.

Description

technical field [0001] The invention relates to the field of hydrophobic materials, in particular to a hydrophobic polymer membrane material. Background technique [0002] The hydrophobicity of a solid surface refers to the physical property that its surface and water repel each other. When the liquid drop contacts the solid surface to achieve a three-phase equilibrium of solid, liquid, and gas, the angle between the contact line of the solid and the droplet interface is called the contact angle. ; The lower the solid surface energy, the larger the water contact angle. When the contact angle of water droplets on the solid surface is greater than 90°, the solid surface is hydrophobic, and the water contact angle of the superhydrophobic material is greater than or equal to 150°. [0003] For example, the surface energy of PE in the polymer is 31-33mN / m, and the water contact angle of the smooth HDPE film surface is between 90-100°, which is a weakly hydrophobic material. In ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08J5/18C08L23/06C08L23/12C08L67/02C08L27/16C08L27/18C08L83/04C08L33/04C08K3/26C08K3/22C08K3/36C08K3/30C08K3/34B29D7/01

CPCC08J5/18B29D7/01C08K2201/011C08K2201/003C08J2323/06C08J2323/12C08J2367/02C08J2327/16C08J2427/18C08J2483/04C08J2433/04C08K2003/265C08K2003/2227C08K2003/2224C08K2003/2241C08K2003/2296C08K2003/222C08K2003/3045C08K3/36C08K3/346C08K2003/267

Inventor 陆冲祁若轩陈昊唐涛屠沁玮

Owner EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com