A method for measuring weak magnetic la 1-x sr x mno 3 Method for Epitaxial Thin Film Layered Magnetic Structures

A technology of epitaxial thin film and magnetic structure, which is applied in the parts of electromagnetic equipment, the manufacture/processing of electromagnetic devices, and the selection of materials, etc., can solve the problems of time-consuming and laborious, weak sample magnetism, and difficult to guarantee test accuracy, and achieve high efficiency. , the method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

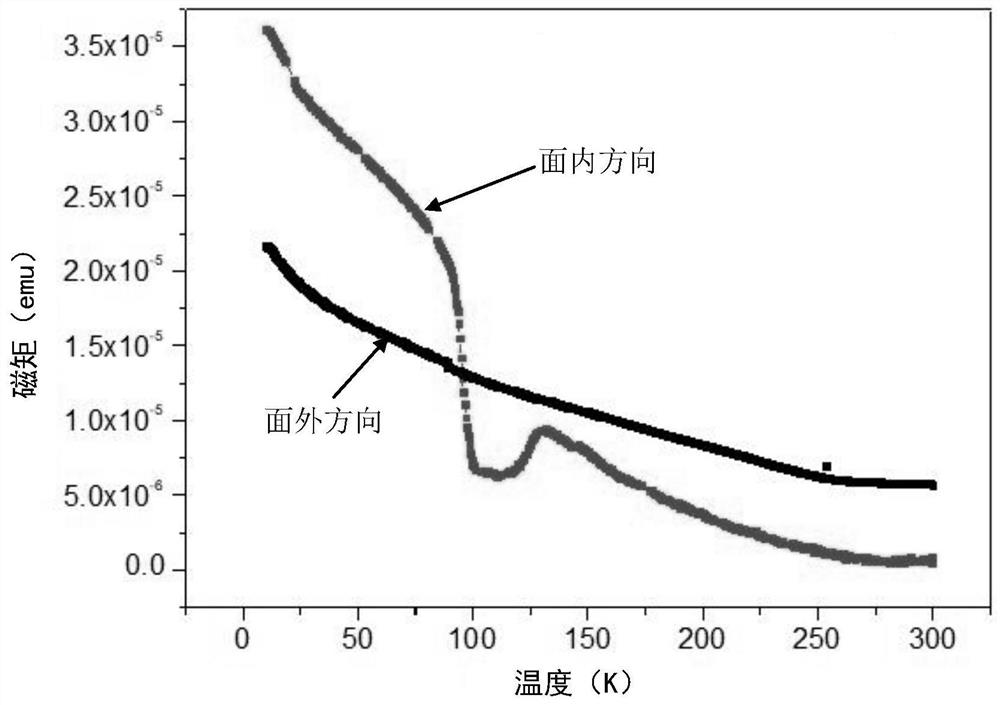

[0024] (1) In order to prepare La with low Sr doping ratio, weak magnetic properties and thickness below 100 nm 1-x Sr x MnO 3 Epitaxial thin film (0≤x≤0.2), first prepared by sintering method L a0.825 Sr 0.175 MnO 3 target material; and then use PLD technology to deposit a thickness of 60 nm La 0.825 Sr 0.175 MnO 3 For the epitaxial thin film, the deposition rate is 2nm / min; after the deposition is completed, the cooling rate of the thin film is 10K / min, down to room temperature.

[0025] (2) Take the above film sample out of the PLD under the protection of inert gas, and then place it in the liquid helium chamber of PPMS. At this time, a magnetic field of 1000Oe is applied to the film sample for magnetization, and under the action of the magnetic field, a 10K / min The cooling rate is to cool the sample down to 10K, at which point the applied magnetic field is reduced to zero.

[0026] (3) Apply a reverse magnetic field of 10Oe to the above-mentioned thin film sample i...

Embodiment 2

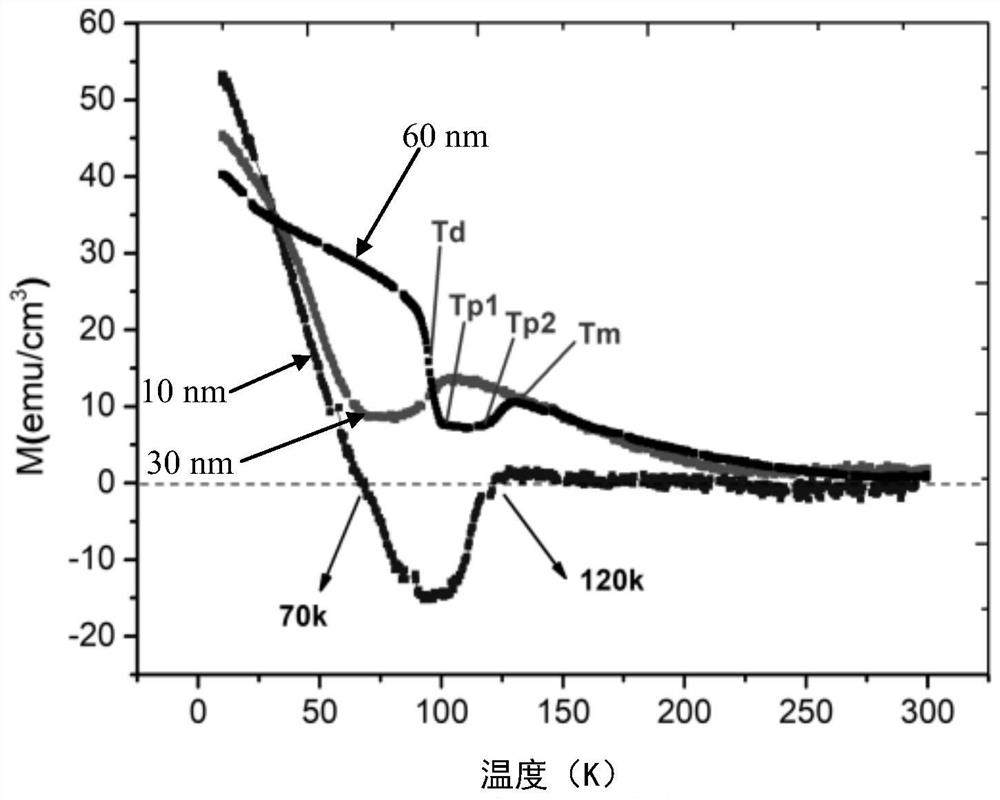

[0029] (1) In order to prepare La with low Sr doping ratio, weak magnetic properties and thickness below 100 nm 1-x Sr x MnO 3 Epitaxial thin films (0≤x≤0.2), first prepared by sintering La 0.825 Sr 0.175 MnO 3 The target material; then using PLD technology, under the conditions of laser energy of 118mJ, frequency of 2Hz, oxygen pressure of 10Pa and substrate temperature of 570°C, the thicknesses of 10, 30 and 60 nanometers were respectively deposited on the STO (001) substrate. La 0.825 Sr 0.175 MnO 3 For the epitaxial thin film, the deposition rate is 2nm / min; after the deposition is completed, the cooling rate of the thin film is 10K / min, down to room temperature.

[0030] (2) The above thin film sample is taken out from the PLD under the protection of inert gas, and then placed in the liquid helium chamber of PPMS. At 300K, a magnetic field of 1000Oe is applied to the thin film sample for magnetization, and under the action of the magnetic field, a 10K / min The cool...

Embodiment 3

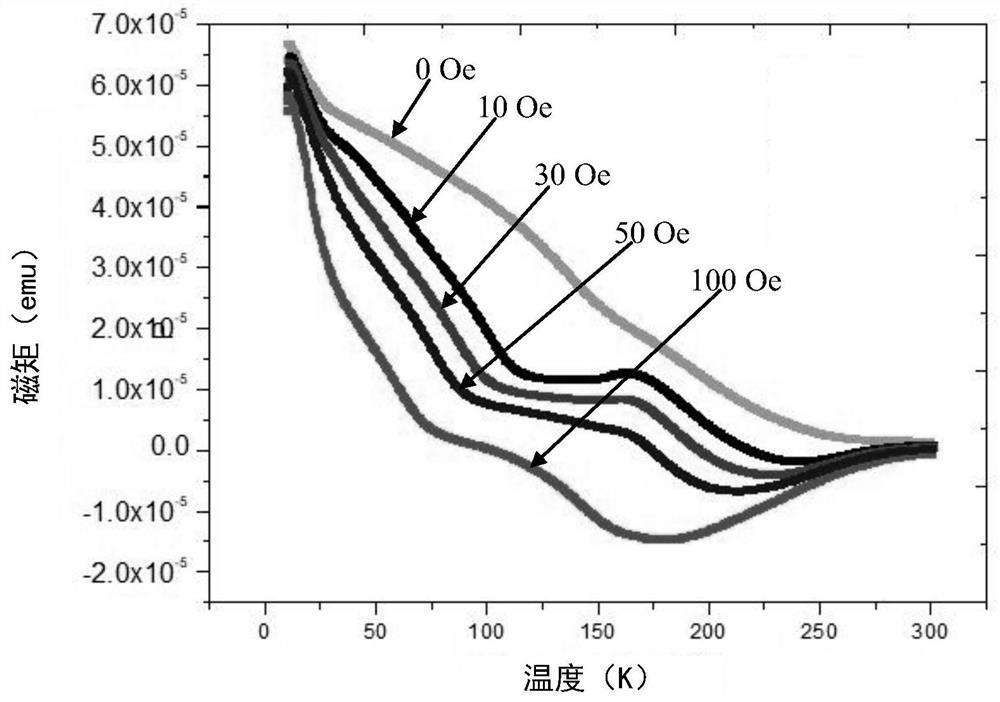

[0034] (1) In order to prepare La with low Sr doping ratio, weak magnetic properties and thickness below 100 nm 1-x Sr x MnO 3 Epitaxial thin films (0≤x≤0.2), first prepared by sintering La 0.825 Sr 0.175 MnO 3 target material; and then use PLD technology to deposit a thickness of 60 nm La 0.825 Sr 0.175 MnO 3 For the epitaxial thin film, the deposition rate is 2nm / min; after the deposition is completed, the cooling rate of the thin film is 10K / min, down to room temperature.

[0035] (2) The above-mentioned thin film sample is taken out from the PLD under the protection of an inert gas, and then placed in the liquid helium chamber of PPMS. At this time, a magnetic field of 1000Oe is applied to the thin film sample for magnetization, and under the action of the magnetic field, a 5K / min The cooling rate is to cool the sample down to 10K, at which point the applied magnetic field is reduced to zero.

[0036] (3) Apply reverse magnetic fields of 10, 30, 50 and 100 Oe to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com