Shape memory polymer foam material and preparation method and application thereof

A technology of memory polymer and foam material, which is applied in the field of shape memory polymer foam material and its preparation, can solve the problems of shape memory polymer hardness and shaping temperature unsuitable for human wear, and achieve product experience improvement, not easy to crack, and controllable good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] On the other hand, the embodiment of the present invention provides the preparation method of the shape memory polymer foam material, which includes the following steps:

[0055] S01: heating and mixing polyester diol, polyether diol, crosslinking agent, and foaming agent with a mass ratio of 50: [1-15]: [0.1-1]: [0.4-4];

[0056] S02: Adding a curing agent and a catalyst with a mass ratio of [1.25-4.5]:0.1 to the mixed treatment product for mixed treatment, heating and reacting to obtain the polymer material.

[0057] In the step S01, the cross-linking and foaming processes are carried out synergistically, and the cross-linking process enables the polymer precursor to form a certain strength, so that the foaming process can be controlled. The heating temperature is 50-80° C., and controlling the temperature within an appropriate range can make the cross-linking process controllable on the one hand, taking into account the reaction rate and the stability of the reaction...

Embodiment 1

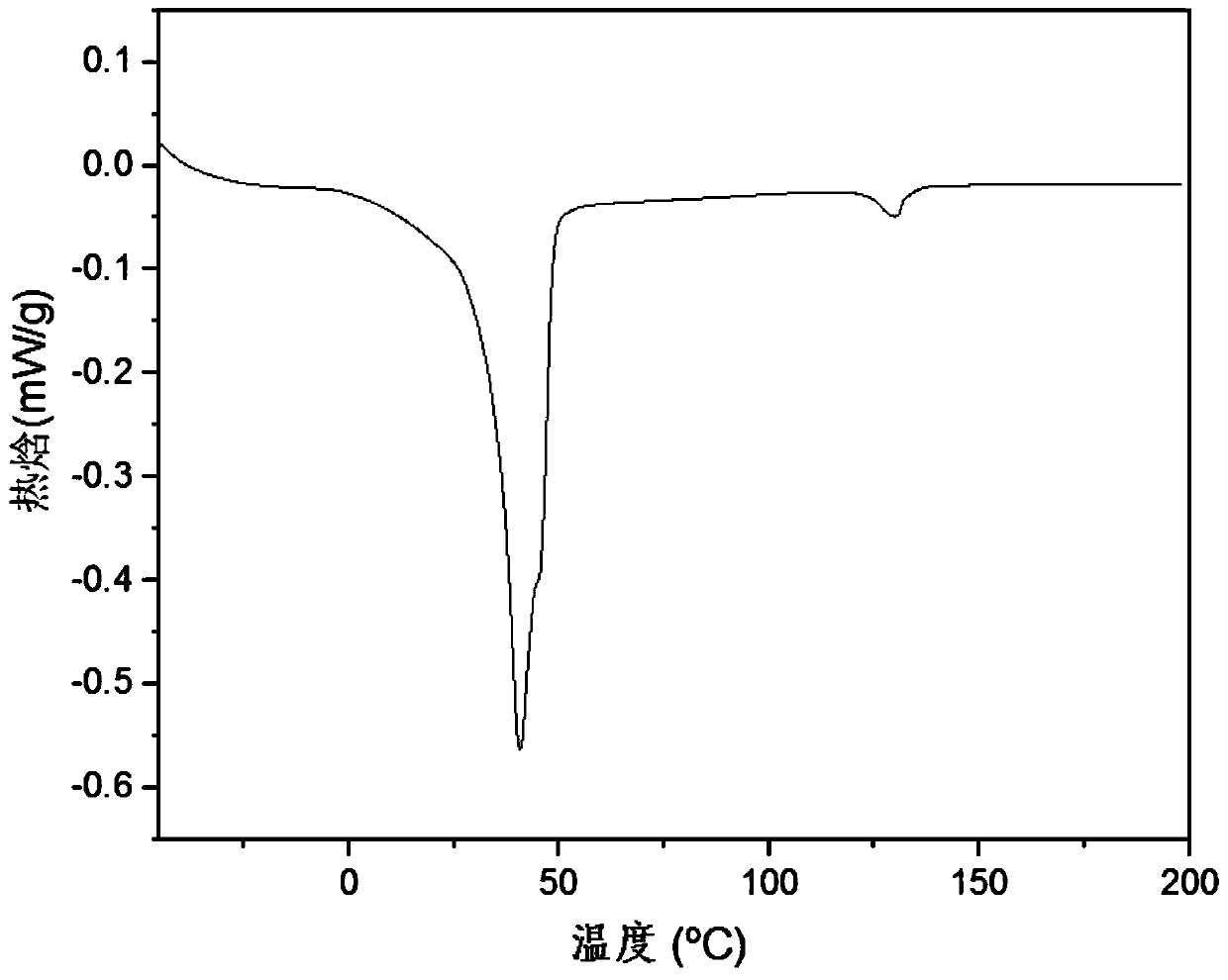

[0064] Select 50 parts of molecular weight 3000 polyhexamethylene adipate diol as the main raw material, 5 parts of polyethylene glycol with a molecular weight of 400 as the secondary raw material, add 0.5 part of pentaerythritol as the crosslinking agent, and 0.5 part of deionized water as the chemical Blowing agent, 0.5 parts of dichloromethane is a chemical blowing agent; The above-mentioned raw materials are heated to 50 ℃ and mixed uniformly; Then adding 8 parts of isocyanate mass fractions is liquefied MDI (trade name Bayer CD-C) of 29 wt% for curing agent and 0.1 part of dibutyltin dilaurate as a catalyst, after rapid stirring for 30 minutes, pour the mixture into a mold, and place the mixture in an oven at 60°C for 10 hours to react to prepare the flexible foam. Such as figure 1 As shown, the prepared flexible polyurethane foam has a crystalline melting peak with low crystallinity at about 45°C, and a crystallization melting peak with relatively complete crystallizatio...

Embodiment 2

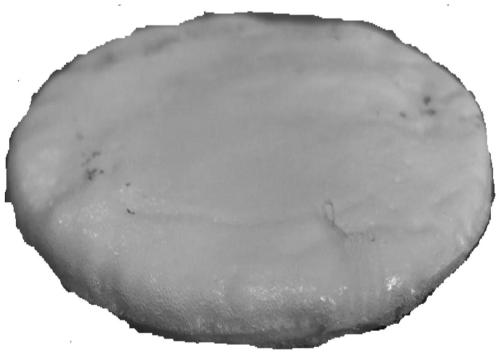

[0066] Select 50 parts of polybutylene adipate diol with a molecular weight of 4000 as the main raw material, 10 parts of polypropylene glycol with a molecular weight of 600 as the secondary raw material, add 1 part of glycerol as a crosslinking agent, and 0.25 parts of deionized water as a chemical Foaming agent, 0.25 parts of n-heptane is a chemical foaming agent; the above raw materials are heated to 70 ° C and mixed uniformly; Butyl tin is used as a catalyst. After stirring rapidly for 30 minutes, the mixture is poured into a mold, and the mixture is placed in an oven at 70° C. for 8 hours to react to prepare the soft foam. Such as image 3 As shown, the prepared flexible polyurethane foam can be easily compressed into a compact material at room temperature (about 25°C); and when placed in an oven at 80°C for 2 minutes, the compressed compact material will gradually return to fluffy The foam structure (such as Figure 4 Shown), the Shao A hardness is about 40, and the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com