A repair preparation method of a trace amount of sn-doped perovskite film and all-inorganic perovskite solar cell

A perovskite and inorganic calcium technology, applied in the manufacture of circuits, electrical components, final products, etc., can solve the problems of perovskite film quality, limitations, and affecting the extraction efficiency of interface charges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment is an all-inorganic perovskite solar cell, which sequentially includes a layered conductive glass layer, an electron transport layer, an all-inorganic perovskite layer and a carbon electrode layer.

[0036] Use the sol-gel method to coat a layer of dense titanium dioxide film on the conductive glass as an electron transport layer. After heat treatment at 400-450°C, perform titanium tetrachloride hydrolysis reaction treatment on the dense titanium dioxide film, and place it in a box-type resistance furnace after drying. Sintering at 450-500°C for later use.

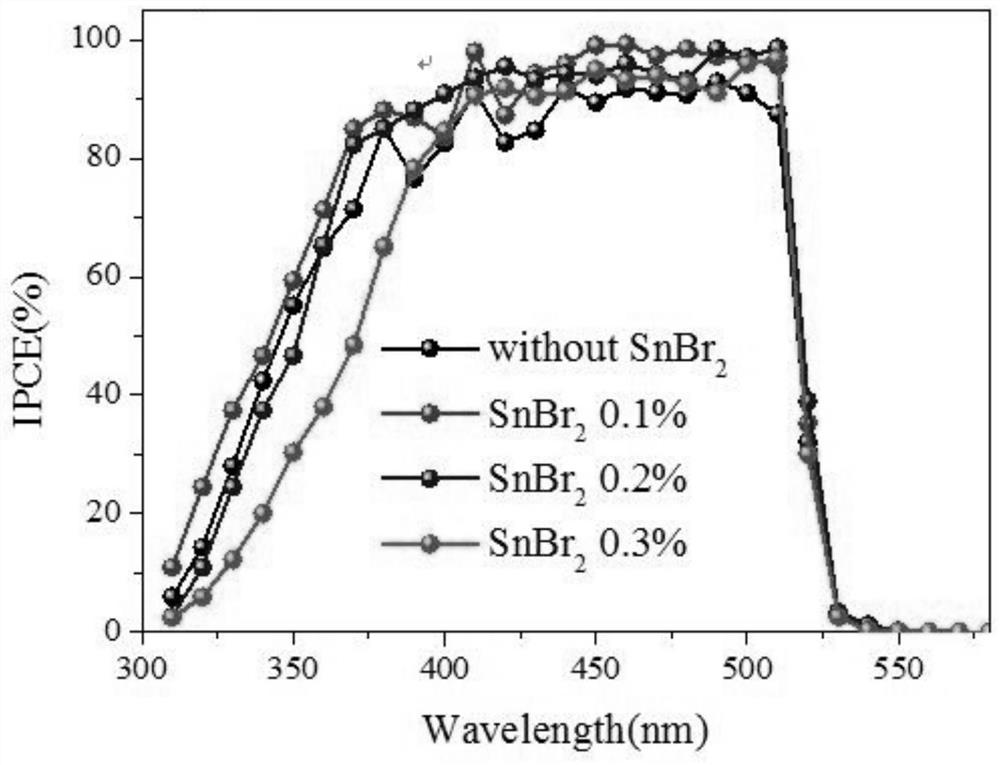

[0037] Dissolve lead bromide and tin bromide in DMF solution to form base solution, the molar concentration of lead bromide is 1mol / L, and the molar concentration of tin bromide is 0.001mol / L. Cesium bromide was dissolved in DMSO to form a modification solution, and the molar concentration of cesium bromide was 1mol / L. The substrate solution was spin-coated onto the electron transport layer to form ...

Embodiment 2

[0041]This embodiment is an all-inorganic perovskite solar cell, which sequentially includes a layered conductive glass layer, an electron transport layer, an all-inorganic perovskite layer and a carbon electrode layer.

[0042] Use the sol-gel method to coat a layer of dense titanium dioxide film on the conductive glass as an electron transport layer. After heat treatment at 400-450°C, perform titanium tetrachloride hydrolysis reaction treatment on the dense titanium dioxide film, and place it in a box-type resistance furnace after drying. Sintering at 450-500°C for later use.

[0043] Dissolve lead bromide and tin bromide in the DMF solution to form a base solution, the molar concentration of lead bromide is 1mol / L, and the molar concentration of tin bromide is 0.002mol / L. Cesium bromide was dissolved in DMSO to form a modification solution, and the molar concentration of cesium bromide was 1mol / L. The substrate solution was spin-coated onto the electron transport layer to ...

Embodiment 3

[0047] This embodiment is an all-inorganic perovskite solar cell, which sequentially includes a layered conductive glass layer, an electron transport layer, an all-inorganic perovskite layer and a carbon electrode layer.

[0048] Use the sol-gel method to coat a layer of dense titanium dioxide film on the conductive glass as an electron transport layer. After heat treatment at 400-450°C, perform titanium tetrachloride hydrolysis reaction treatment on the dense titanium dioxide film, and place it in a box-type resistance furnace after drying. Sintering at 450-500°C for later use.

[0049] Dissolve lead bromide and tin bromide in DMF solution to form base solution, the molar concentration of lead bromide is 1mol / L, and the molar concentration of tin bromide is 0.003mol / L. Cesium bromide was dissolved in DMSO to form a modification solution, and the molar concentration of cesium bromide was 1mol / L. The substrate solution was spin-coated onto the electron transport layer to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com