Metal-based material for preparation of crystallizer or tuyere as well as preparation method of metal-based material

A metal-based and crystallizer technology, applied in the coating process of metal materials, coatings, etc., can solve the problems of reducing the dilution rate of the substrate, high-temperature wear resistance, reducing substrate deformation, and reducing processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

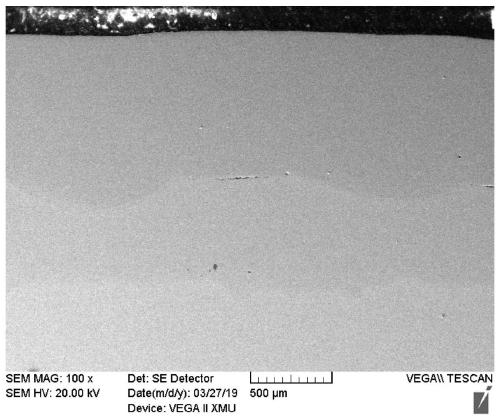

Image

Examples

Embodiment 1

[0033]A metal-based material for preparing crystallizers or tuyeres provided by Embodiment 1 of the present invention includes a copper or copper alloy substrate, a transition layer coated on the surface of the copper or copper alloy substrate, and a high wear-resistant material bonded on the transition layer. The working layer, wherein the material of the transition layer is at least one of pure Co metal, pure Ni metal, pure Cr metal, pure Cu metal, pure Mo metal, pure Ag metal, NiCr or MCrAlY alloy, and M represents Ni, Co or NiCo, the material of the high wear-resistant working layer is at least one of iron-based alloys, nickel-based alloys, cobalt-based alloys, copper-based alloys or cermets, wherein the copper-based alloys include CuMo alloys, copper + chromium carbide, cermets Adding at least one of tungsten carbide, chromium carbide, titanium carbide, tantalum carbide, aluminum oxide, chromium oxide, and titanium oxide ceramics to at least one of iron-based alloys, nicke...

Embodiment 2

[0038] Embodiment 2 of the present invention provides a method for preparing a metal-based material for preparing a crystallizer or a tuyere, the method comprising:

[0039] Step 1: Pretreat and preheat the surface of the copper or copper alloy substrate. The pretreatment at least includes degreasing and sandblasting the surface of the copper or copper alloy substrate. The preheating temperature is 20°C to 400°C. The time is 30 minutes to 120 minutes;

[0040] Step 2: Prepare a transition layer on the surface of the copper or copper alloy substrate by metallurgical bonding. The material of the transition layer is pure Co metal, pure Ni metal, pure Cr metal, pure Cu metal, pure Mo metal, pure Ag metal, NiCr Or at least one of MCrAlY alloys, M represents Ni, Co or NiCo;

[0041] Specifically, a transition layer is prepared on the surface of the copper or copper alloy substrate by laser spraying, the specific parameters of laser spraying are: laser power 1-10kW, laser head scann...

Embodiment 3

[0048] Embodiment 3 of the present invention provides a specific method for preparing metal-based materials for crystallizers or tuyere, the method is as follows:

[0049] Materials used: the powder is Co and Ni45A, the substrate is 10mm thick chrome-zirconium copper plate

[0050] Equipment used: Raycus 4kW semiconductor fiber coupled laser (RFL-A4000D), fiber core diameter is 100μm, circular spot diameter is 0.5-5mm, focal length is 200mm, 6-axis robot system, 5mm coaxial powder feeding head

[0051] The preparation method of wear-resistant coating (high wear-resistant working layer) on 10mm thick chrome-zirconium copper plate comprises the following steps:

[0052] 1) Degreasing and sandblasting the surface of the chrome-zirconium copper plate to increase the absorption rate of the laser;

[0053] 2) Dry the Co and Ni45A powders at 120°C for 1 hour for use;

[0054] 3) Preheat the chrome-zirconium copper plate at 300°C for 30 minutes;

[0055] 4) The transition layer was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com