PLGA cytoskeleton for articular cartilage repair and preparation method and application of PLGA cytoskeleton for articular cartilage repair

A technology of cell scaffolds and chondrocytes, applied in the field of medicine, can solve problems such as unsatisfactory treatment results, poor bionic effects, and long treatment cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1: Preparation of PLGA porous scaffold

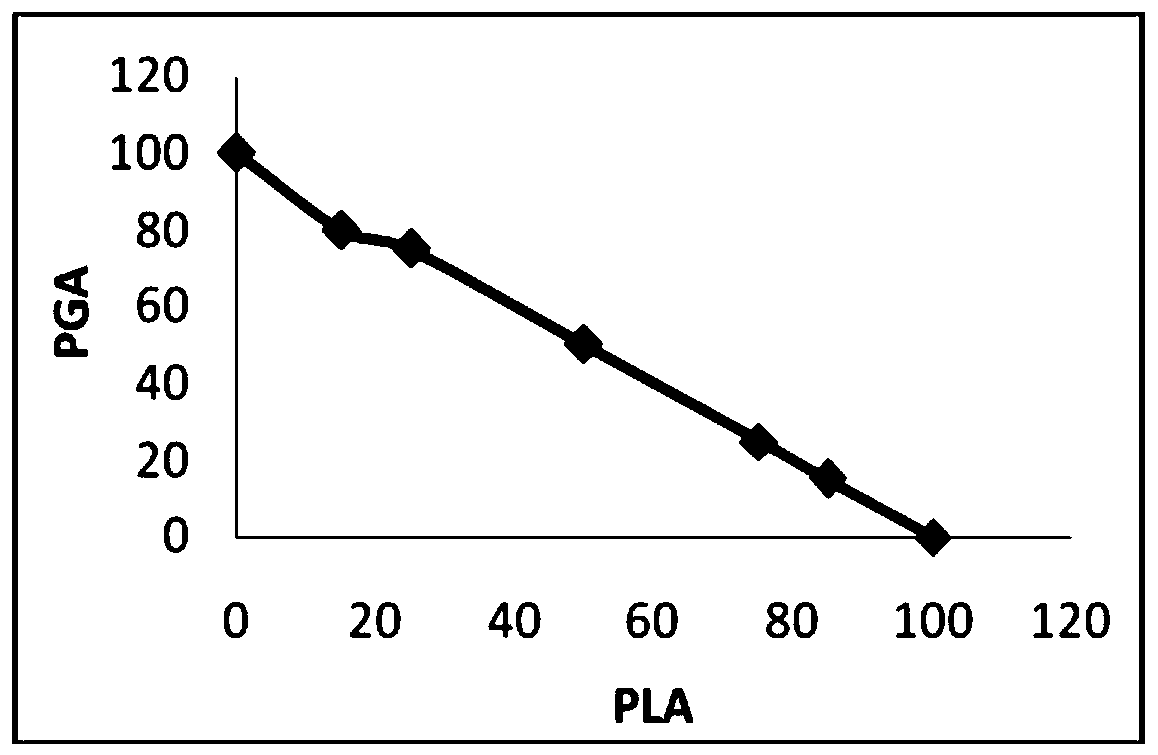

[0078] 1. Preparation of PLGA porous scaffold. The scaffold part of the articular cartilage repair material uses polylactic acid-glycolic acid (PLGA) as the matrix material, which is composed of organic polymer polylactic acid (PLA) and polyglycolic acid (PGA), according to a certain gradient ratio (polylactic acid (PLA): Polyglycolic acid (PGA) = 100:0, 85:15, 75:25, 50:50, 25:75, 15:85, 0:100) polymerization product ( figure 1 ).

[0079] Polylactic acid (PLA), polyglycolic acid (PGA), polylactic acid-glycolic acid (PLGA) monomer chemical structure formula is as follows:

[0080] Polylactic acid [poly(lactic acid), PLA]:

[0081] Polyglycolic acid [poly(glycolic acid), PGA]:

[0082] Polylactic-co-glycolic acid [poly(lactic-co-glycolic acid), PLGA]:

[0083] Prepare the PLGA porous scaffold by freeze-drying technique, the steps are as follows:

[0084] a) PLA / The PGA polymerization product—polylactic ac...

Embodiment 2

[0110] Example 2: Primary culture of adult cells

[0111] 1. Chondrocytes. Adult chondrocytes are derived from articular hyaline cartilage in nonweight-bearing areas.

[0112] a) Cartilage sampling preparation. Items to be prepared include trypsin, type II collagenase, DMEM high-glucose medium, PBS buffer, pipettes, culture dishes or flasks of different capacities, centrifuge tubes, filters, gauze, surgical equipment such as tweezers, scissors, etc. for disinfection after supplies.

[0113] b) Cartilage sampling. After anesthesia, disinfect with povidone iodine and deiodine with 75% alcohol, take about 50-100 mg of articular hyaline cartilage from non-weight-bearing parts, and put it into a petri dish filled with PBS buffer.

[0114] c) Repeated pipetting and washing with cold PBS buffer containing antibiotics 3 times. After the third wash, let stand for 5 minutes, discard the upper liquid and floating tissue, and move the cartilage tissue into a clean sterile vessel.

...

Embodiment 3

[0134] Example 3: Preparation of platelet-rich plasma (PRP) and its release of growth-promoting factors

[0135] 1. Using a 20ml sterile syringe and a vacuum blood collection tube containing ACD-A anticoagulant, draw about 18ml of blood at room temperature (22°C), and put the blood into four 5ml centrifuge tubes, 4ml in each tube. Platelet-rich plasma preparation should be completed within 4 to 6 hours.

[0136] 2. Preparation of platelet-rich plasma. Platelet-rich plasma with effective concentration was prepared by secondary centrifugation, and the activity levels of cytokines PDGF and TGF-β1 in platelet plasma prepared by this method increased significantly (P<0.01).

[0137] a) Place 4ml of each tube symmetrically in a centrifuge, centrifuge for the first time at 200-400g×10min, take 3mm of plasma above and below the buffy coat after centrifugation, and put it in another centrifuge tube,

[0138] b) Perform a second centrifugation at 200-400 g×10 min, remove the supernata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com