A kind of preparation method of high-nickel ternary material coated with lithium cobalt oxide

A high-nickel ternary material, lithium cobalt oxide technology, applied in electrical components, positive electrodes, active material electrodes, etc., can solve problems such as unfavorable ternary material processing performance, deterioration of ternary material cycle and storage performance, etc. Storage and cycle performance, improved rate performance and discharge capacity, and the effect of controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the lithium cobaltate-coated high-nickel ternary material of the present invention comprises the following steps, S1: weighing the precursor Ni of the high-nickel ternary material x co y m 1-x-y (OH) 2 and alkaline solution, where the precursor Ni x co y m 1-x-y (OH) 2 In 0.65≤x<1, 0<y≤0.20, the alkaline solution is an aqueous solution of one or more of the alkaline substances sodium hydroxide, potassium hydroxide or lithium hydroxide, the addition of the alkaline substance The amount is 2 to 5% of the total mass of the precursor of the high-nickel ternary material, and the weighed precursor and the alkaline solution are mixed evenly in a protective gas atmosphere, and the protective gas is nitrogen, helium, neon One or more of gas, argon, krypton and xenon, and then placed in a vacuum oven with a temperature controlled at 80-120°C for 5-12 hours to obtain a dry mixed powder;

[0026] S2: Put the above-mentioned dried mixed powder in the...

Embodiment 1

[0031] 100g high nickel ternary material precursor Ni 0.85 co 0.10 mn 0.05 (OH) 2 Mix with 50mL NaOH solution and stir to form a uniform slurry, wherein the mass of NaOH is 3% of the total mass of the precursor. Then, place the slurry in a vacuum oven at 100°C for 6 hours, and place the dried precursor in an ozone oxidation In the device, ozone gas with a humidity of 40% was introduced at a flow rate of 3 L / min for 1 h; secondly, the oxidized precursor was washed three times with deionized water at 50 ° C, and the precursor obtained after suction filtration was placed in 120 ℃ in a vacuum drying oven for 4 hours; finally, the dried precursor was mixed with lithium hydroxide at a ratio of 1:1.01, placed in a muffle furnace in an oxygen atmosphere, and the heating rate was controlled at 2°C / min. From room temperature to 780°C, heat preservation for 15h, and natural cooling to 100°C to obtain LiCoO 2 Coated high nickel ternary material.

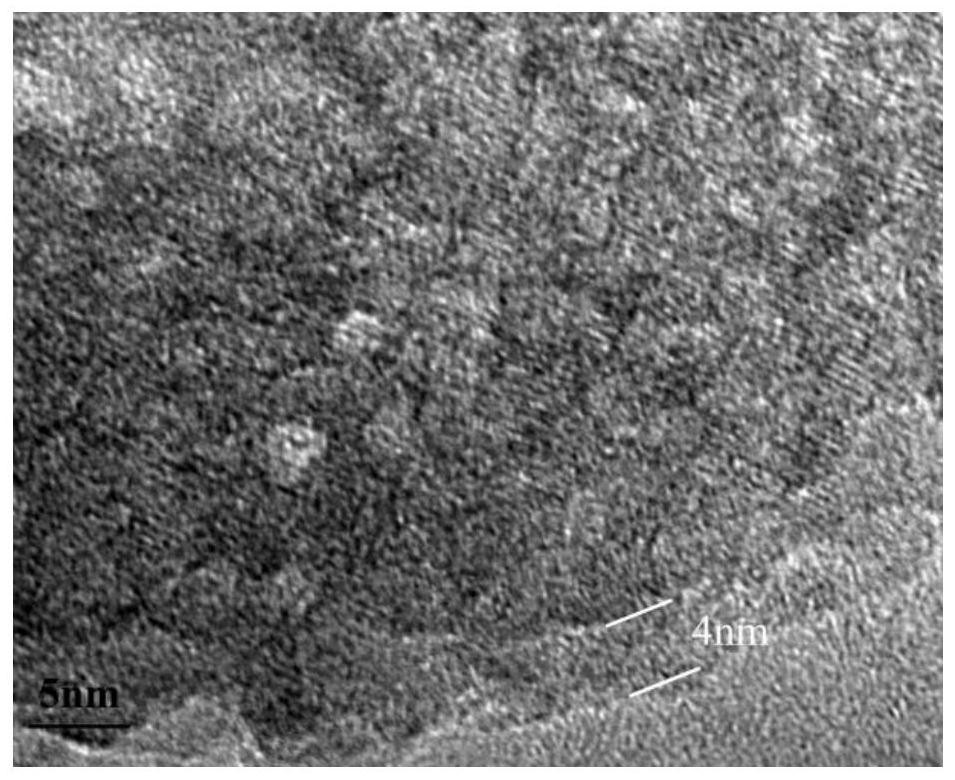

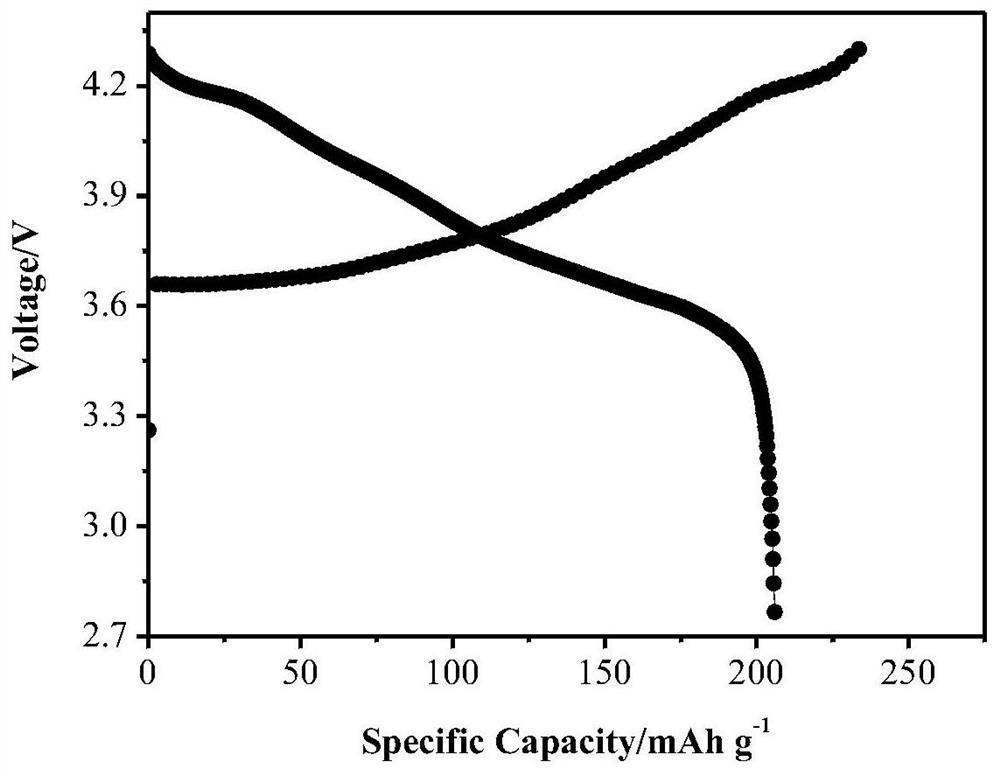

[0032] LiCoO obtained above 2 Coate...

Embodiment 2

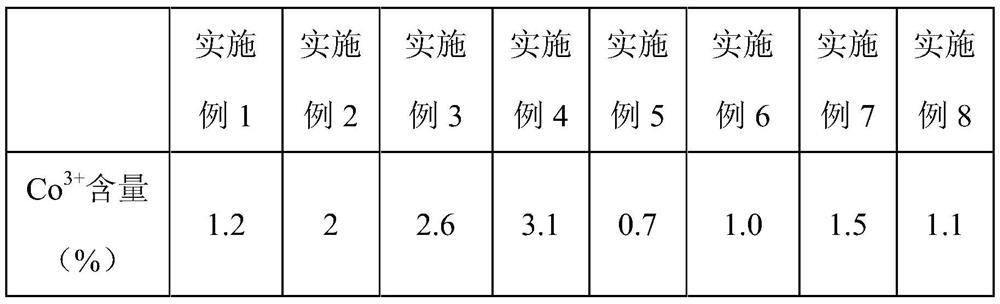

[0034] The precursor Ni of the mixed NaOH dried in embodiment 1 0.85 co 0.10 mn 0.05 (OH) 2 Placed in the ozone oxidation reaction device, with the flow rate of 3L / min, the ozone gas with a humidity of 40% was introduced for 2h, and the other steps were the same as in Example 1 to obtain LiCoO 2 Coated high nickel ternary material.

[0035] The positive electrode of the battery was produced and tested in the same steps as in Example 1. The electrochemical performance, moisture and residual alkali content of the product are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com