A near-infrared luminescent bismuth-doped strontium chloropentaborate crystal and its preparation method

A near-infrared and pentaboric acid technology, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of bismuth laser output that have not yet been realized, and achieve the effects of convenient large-scale production, long fluorescence lifetime and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

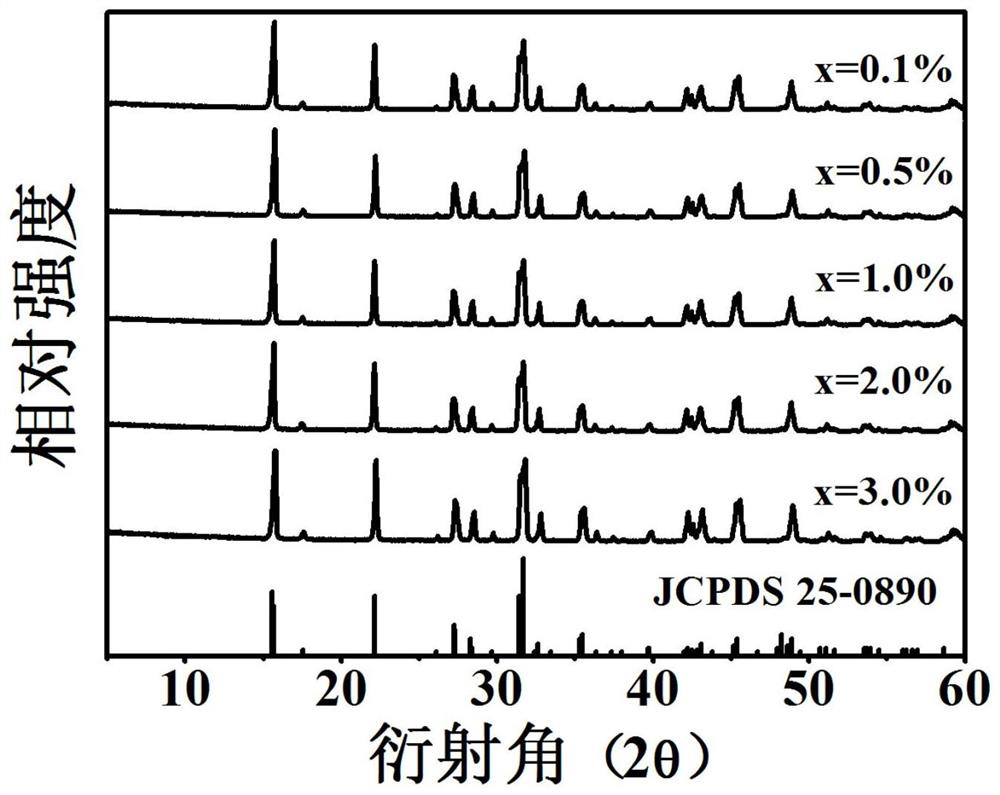

[0031] Select strontium carbonate, boric acid, strontium chloride hexahydrate, and bismuth trioxide as the starting compound raw materials, and weigh the compound raw materials respectively according to the stoichiometric ratio of each element, a total of 5 groups, and the proportion is as follows:

[0032] (1) Sr:B:O:Cl:Bi=1.998:5:9:1:0.002, corresponding to x=0.1%;

[0033] (2) Sr:B:O:Cl:Bi=1.99:5:9:1:0.01, corresponding to x=0.5%;

[0034] (3) Sr:B:O:Cl:Bi=1.98:5:9:1:0.02, corresponding to x=1.0%;

[0035] (4) Sr:B:O:Cl:Bi=1.96:5:9:1:0.04, corresponding to x=2.0%;

[0036] (5) Sr:B:O:Cl:Bi=1.94:5:9:1:0.06, corresponding to x=3.0%;

[0037] After grinding and mixing the raw materials evenly, put them into a corundum crucible; place the corundum crucible in a corundum boat and put it into a high-temperature box-type electric furnace. Strictly control the heating rate, pre-calcined at 773K for 5 hours, cooled to room temperature, and ground and mixed; then calcined at 1173K...

Embodiment 2

[0044] Strontium carbonate, boron trioxide, strontium chloride hexahydrate, and bismuth trioxide are selected as starting compound raw materials, and the molar ratio of each element is Sr:B:O:Cl:Bi=1.98:5:9:1:0.02 , corresponding to x=1.0%, weigh the compound raw materials respectively, after the mixture is ground evenly, put it into a corundum crucible, place the crucible in a corundum boat, and put it into a high-temperature box-type electric furnace. Strictly control the heating rate, pre-burn at 773K for 5 hours, cool to room temperature, grind and mix; then calcinate at 1173K for 10 hours, cool to room temperature with the furnace and grind evenly, the obtained sample is in a reducing atmosphere at 1173K (graphite powder is not completely burned) generated carbon monoxide) for 2.5 hours, cooled to room temperature, and ground to obtain bismuth-doped strontium chloropentaborate crystals. XRD pattern analysis shows that it is Sr 2 B 5 o 9 The Cl phase belongs to the orth...

Embodiment 3

[0046] Strontium carbonate, boric acid, strontium chloride hexahydrate, and bismuth trioxide are selected as starting compound raw materials, and the molar ratio of each element is Sr:B:O:Cl:Bi=1.98:5:9:1:0.02, corresponding to x = 1.0%, the compound raw materials were weighed respectively, and the mixture was ground evenly, and put into a corundum crucible, and the crucible was placed in a corundum boat, and put into a high-temperature box-type electric furnace. Strictly control the heating rate, pre-calcined at 773K for 5 hours, cooled to room temperature, and ground and mixed; then calcined at 1123K for 10 hours, cooled to room temperature with the furnace, and ground evenly. % nitrogen) for 1.5 hours, cooled to room temperature, and ground to obtain bismuth-doped strontium chloropentaborate crystals. XRD pattern analysis shows that it is Sr 2 B 5 o 9 The Cl phase belongs to the orthorhombic crystal system, and the doping of bismuth does not introduce other phases or imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com