A microalloy steel billet corner transverse crack control technology and crystallizer

A technology for crystallizer and casting billet, which is used in the control process of transverse cracks at the corners of microalloyed steel billets and the field of crystallizers, can solve problems such as imperfections and transverse cracks, achieve uniform cooling speed, prevent damage, and improve solidification efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

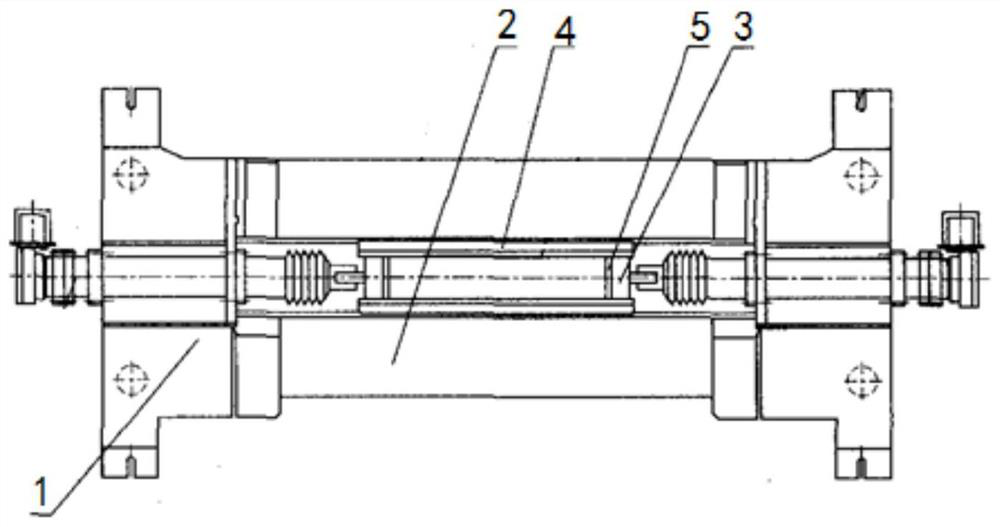

[0045] like figure 1 and figure 2 As shown, a crystallizer is mainly used to cool the high-temperature liquid steel coming out of the tundish, so that the molten steel can be quickly solidified into a billet shell with a certain thickness around it, but the incompletely solidified billet is still liquid steel inside, and then successively After passing through the secondary cooling zone and the air cooling zone at the lower mouth of the crystallizer, until it is completely solidified into a billet of a certain shape. The specific structure of the crystallizer is described in detail below.

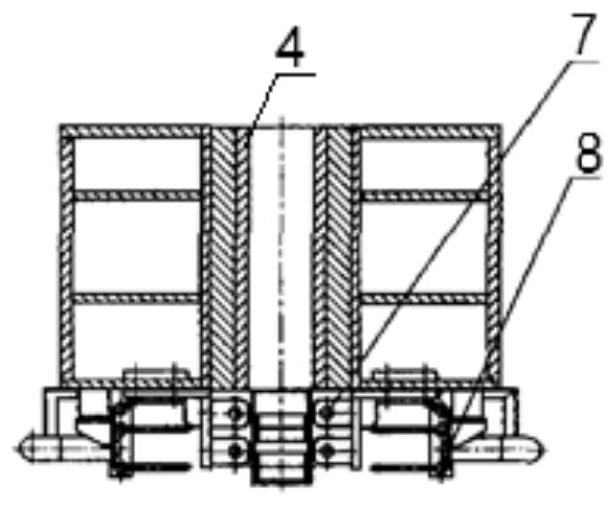

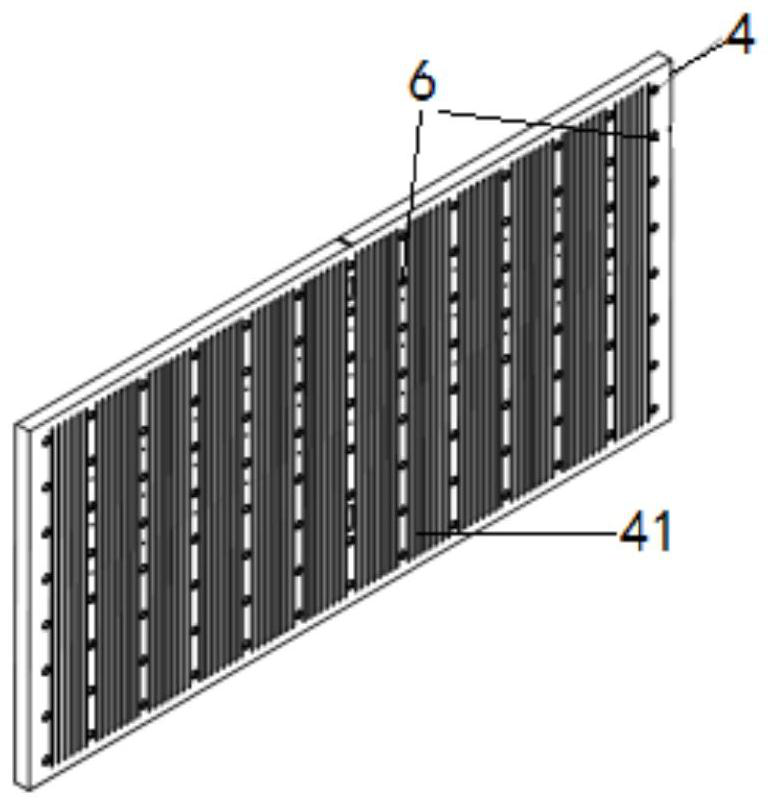

[0046] The crystallizer mainly includes a frame 1 and a wide water tank 2 and a narrow water tank 3 installed vertically on the frame 1. The wide water tank 2 and the narrow water tank 3 are used to provide cooling water to cool molten steel. Wherein, there are two wide-faced water tanks 2, which are arranged symmetrically inside the crystallizer, and a wide-faced copper plate 4 is insta...

Embodiment 2

[0055] A technology for controlling transverse cracks at the corners of microalloy steel slabs, using a crystallizer in Example 1 to produce continuous casting slabs, the main target is continuous casting slabs with a thickness between 210mm and 250mm, including the following step:

[0056] 1. Strong cooling of crystallizer

[0057] Control the cooling water volume of the wide surface of the crystallizer to 4050-4500L / min, and the water volume of the narrow surface to 430-540L / min. The water volume of the wide surface and the narrow surface is set in conjunction with the improved copper plate structure to carry out strong cooling of the molten steel. , in this parameter range. Production of slabs, especially slabs with a thickness ranging from 210mm to 250mm, can greatly improve the solidification efficiency of molten steel in the crystallizer and the high-temperature mechanical properties of the slab shell.

[0058] The reverse taper value of the control mold is 1% to 1.2%....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com