A preparation method of high-density metal azide with arbitrarily regulated packing density

A technology of packing density and azide, which is used in metal azide compositions, azide acid/azide/halide azide, attack equipment, etc. Reduce the detonation power and other problems, and achieve the effects of high detonation power, safe and green preparation process, and low equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

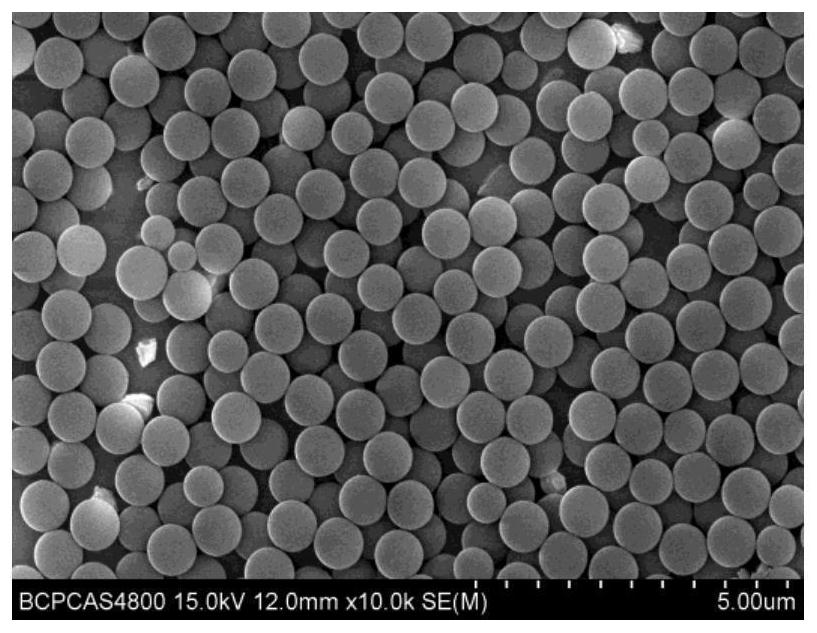

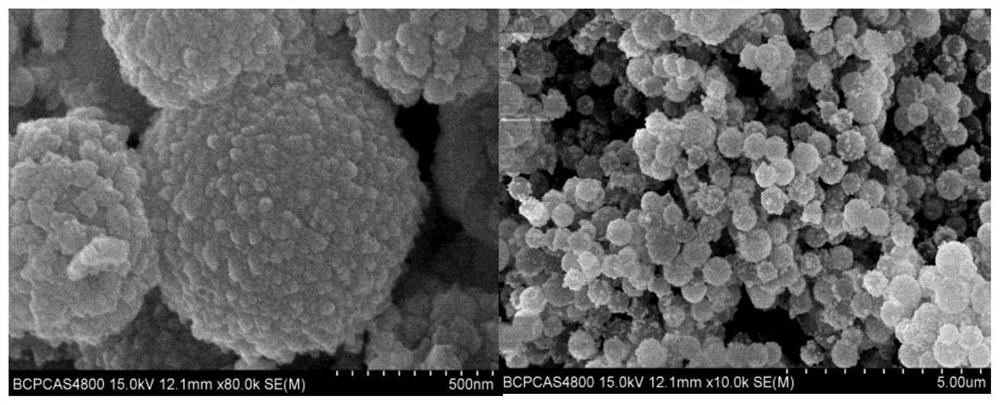

[0090] (1) Take 11 mL of styrene monomer, 40 mL of deionized water, 7 mL of methanol, and 0.08 g of potassium persulfate and stir and mix them. After passing nitrogen gas for about 25 minutes, seal the reaction device and raise the temperature to 75 ° C for 8 hours. After the reaction, the product was separated by centrifugation, washed three times with deionized water, and vacuum-dried at 40° C. to obtain polystyrene microspheres with a particle size of 800 nm. figure 1 It is the SEM characterization figure of the polystyrene microspheres prepared by this method. Depend on figure 1 It can be seen that the particle size of the polystyrene microspheres is about 700nm, the surface is smooth, and the size is basically the same.

[0091] (2) Roughening: Dissolve 6g of potassium dichromate in 100mL of water and add 5mL of concentrated sulfuric acid to make a roughening solution. 1 g of polystyrene microspheres was placed in the roughening solution, stirred and heated to 50°C fo...

Embodiment 2

[0099] (1) Mix 40mL of ethanol, 1% of azobisisobutylcyanide, 5% of polyvinylpyrrolidone and 4mL of styrene monomer, and seal the reaction device after passing nitrogen gas for 30 minutes and raise the temperature to 75°C for 16 hours. After centrifugation, the resulting product was washed three times with ethanol, and vacuum-dried at 70°C to obtain 4.5 μm polystyrene microspheres. Figure 8 It is the SEM characterization figure of the polystyrene microspheres prepared by this method. Depend on Figure 8 It can be seen that the particle size of the polystyrene microspheres is about 4.5 μm, the surface is smooth, and the size is basically the same.

[0100] (2) Roughening: Dissolve 6g of potassium dichromate in 100mL of water and add 5mL of concentrated sulfuric acid to make a roughening solution. Disperse 1 g of polystyrene microspheres in the coarsening solution, stir and heat to 55°C for 30 minutes. Suction filtration, washing with deionized water 3 times.

[0101] (3) Se...

Embodiment 3

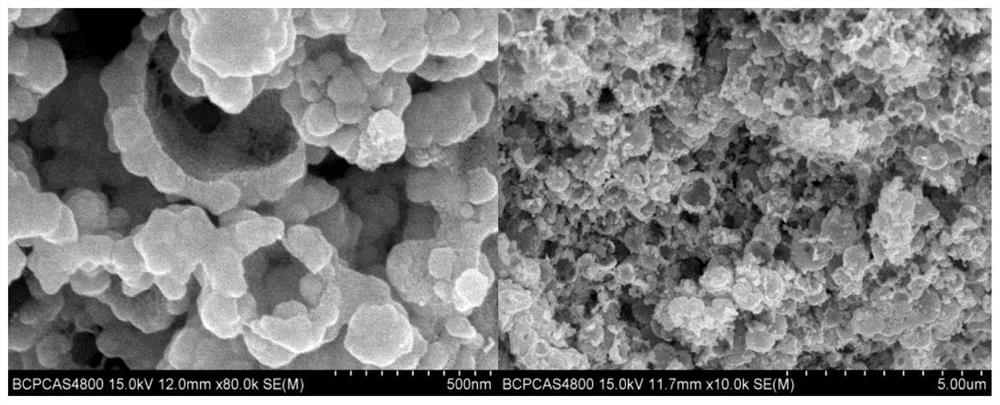

[0109] The micron-sized polystyrene microspheres coated with nano-metallic copper prepared in Example 2 were placed in a tubular sintering furnace and sintered at 450°C for 120 minutes under the protection of nitrogen, and then lowered to room temperature to obtain nanoporous metallic copper-structured polystyrene microspheres. hollow microspheres. The hollow microsphere powder constructed by nanoporous metal copper is transferred into the confinement shell of glass fiber plate with a thickness of 0.4mm and a diameter of 0.8mm, and the available density is about 1.2g / cm 3 The hollow microspheres are constructed of nanoporous copper with constrained shells. The whole constrained shell device is placed in the reactor and azide gas for 12 hours in situ chemical reaction to prepare a packing density of 2.3g / cm 3 The charge mass of the high-density copper azide in a single constrained shell is about 0.46 mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com